Organic fertilizer large heater

1. Rapid heating: It can quickly raise the temperature of the organic fertilizer processing environment in a short time to meet the temperature requirements of the organic fertilizer production process.

2. Good temperature uniformity: A good hot air circulation system or uniform distribution of heating elements can ensure uniform temperature distribution during the heating process to avoid local overheating or overcooling.

3. Intelligent temperature control system: Equipped with advanced temperature sensors and intelligent control systems, it can monitor and accurately control the heating temperature in real time. When the temperature reaches the set value, the heater automatically maintains a constant temperature state to avoid the impact of excessively high or low temperatures on the quality of organic fertilizer.

4. Flexible temperature adjustment: The temperature can be flexibly adjusted according to the actual production situation to meet the needs of temperature changes at different stages in the production of organic fertilizer.

5. Dust-proof design: A certain amount of dust will be generated during the production of organic fertilizer. The design of the heater will take into account dust prevention issues and take measures such as sealing or filtering to prevent dust from entering the equipment and affecting the normal operation and service life of the equipment.

6. High energy utilization: The use of efficient heating elements and optimized heating structures can maximize energy utilization efficiency, reduce energy consumption, and save operating costs.

7. High safety performance: Equipped with a variety of safety protection devices, such as overheat protection, overload protection, leakage protection, etc. When the equipment has an abnormal situation, it can automatically shut down and alarm in time to ensure the safety of the operator and the normal operation of the equipment.

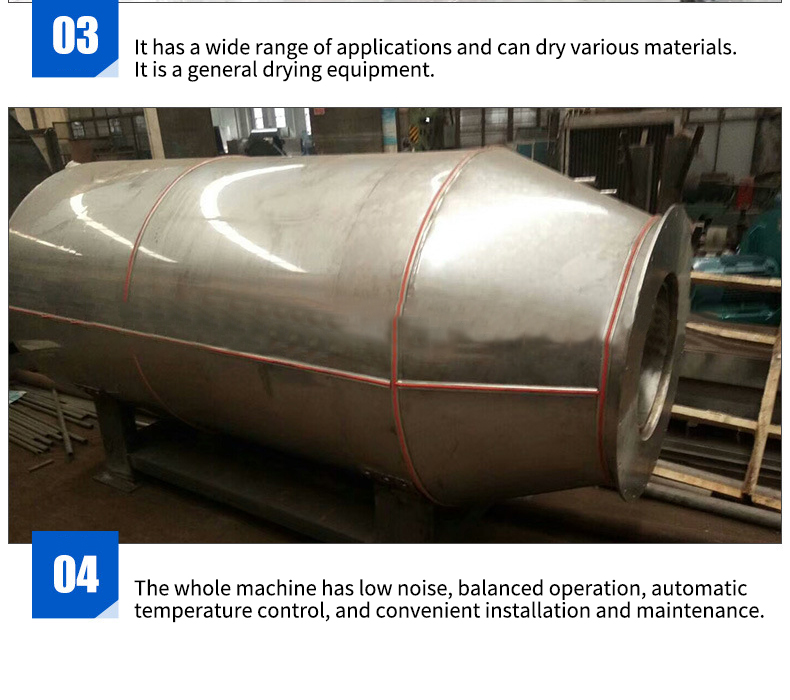

The large organic fertilizer heater is an advanced heating equipment specially designed for the field of organic fertilizer production. It combines multiple advantages such as high efficiency, precision, environmental protection, and safety, and provides reliable temperature guarantee for the processing of organic fertilizer.

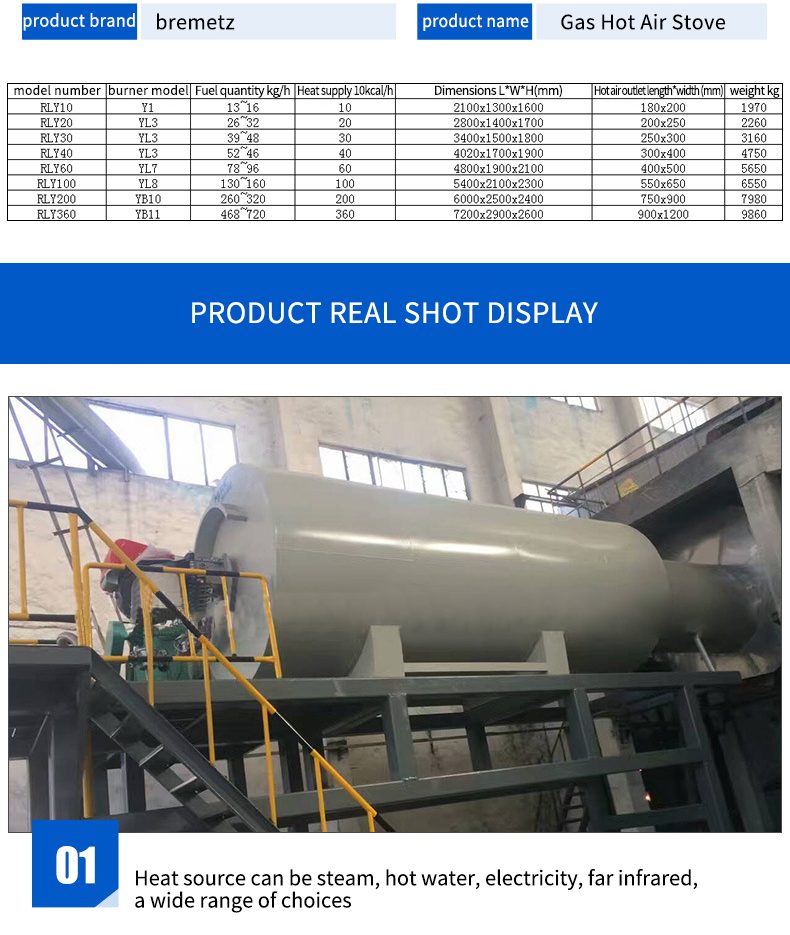

Product name: Gas hot air furnace

Model: RLY10, RLY20, RLY30, RLY40, RLY60, RLY100, RLY200, RLY360.

Burner model: Y1, YL3, YL3, YL3, YL7, YL8, YB10, YB11.

Fuel volume kg/h: 13~16, 26~32, 39~48, 52~66, 78~96, 130~160, 260~320, 468~720

Heat supply 10kcal/h: 10, 20, 30, 40, 60, 100, 200, 360

Dimensions length * width * height (mm): 2100x1300x1 600, 2800x1400x1700, 3400x1500x1800, 4020x1700x1900, 4800x1900x2100, 5400x2100x2300, 6000x2500x2400, 7200x2900x2600

Hot air outlet length and width (mm): 180x200, 200x250, 250x300, 300x400, 400x500, 550x650, 750x900, 900x1200

Weight (kg): 1970, 2260, 3160, 4750, 5650, 6550, 7980, 9860

High power output: This heater has a large power and can generate strong hot air, which can quickly increase the temperature of the organic fertilizer processing space. Whether in a large-scale organic fertilizer production workshop or in an environment where a large amount of organic fertilizer is piled up, it can show excellent heating effect, ensure that the heating speed meets production needs, and effectively shorten the production cycle.

Efficient hot air circulation system: The equipment is equipped with a well-designed hot air circulation mechanism. Through the special air duct and fan layout, the hot air can evenly cover the entire target area to achieve uniform temperature distribution. This is crucial for the drying and fermentation process of organic fertilizer, which can ensure that each part of organic fertilizer can be processed at a suitable temperature, thereby improving the overall quality of organic fertilizer.

Intelligent temperature control system: built-in high-precision temperature sensor and advanced intelligent controller. The temperature sensor can monitor the ambient temperature in real time and accurately, and feed the data back to the controller. The controller accurately adjusts the heating power of the heater according to the preset temperature parameters to ensure that the temperature is always stable within the ideal range. At various stages of organic fertilizer fermentation, users can easily set and adjust the temperature according to the optimal temperature requirements of microbial activity to ensure the smooth progress of the fermentation process.

Wide range temperature adjustment: It has a wide range of temperature adjustment functions to meet the diverse temperature requirements of different links in the organic fertilizer production process. From the preheating of organic fertilizer in the early stage, the constant temperature control during the fermentation process, to the temperature adjustment in the later drying stage, precise control can be achieved through simple operation, providing great flexibility for organic fertilizer production.