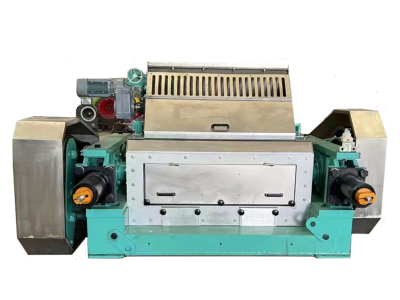

Biomass grinder

1. Significant economic benefits: Biomass pulverizers can convert biomass waste into valuable products, bringing considerable economic benefits to users. By recycling biomass, it can also reduce dependence on traditional energy and resources, reduce production costs, and improve the competitiveness of enterprises.

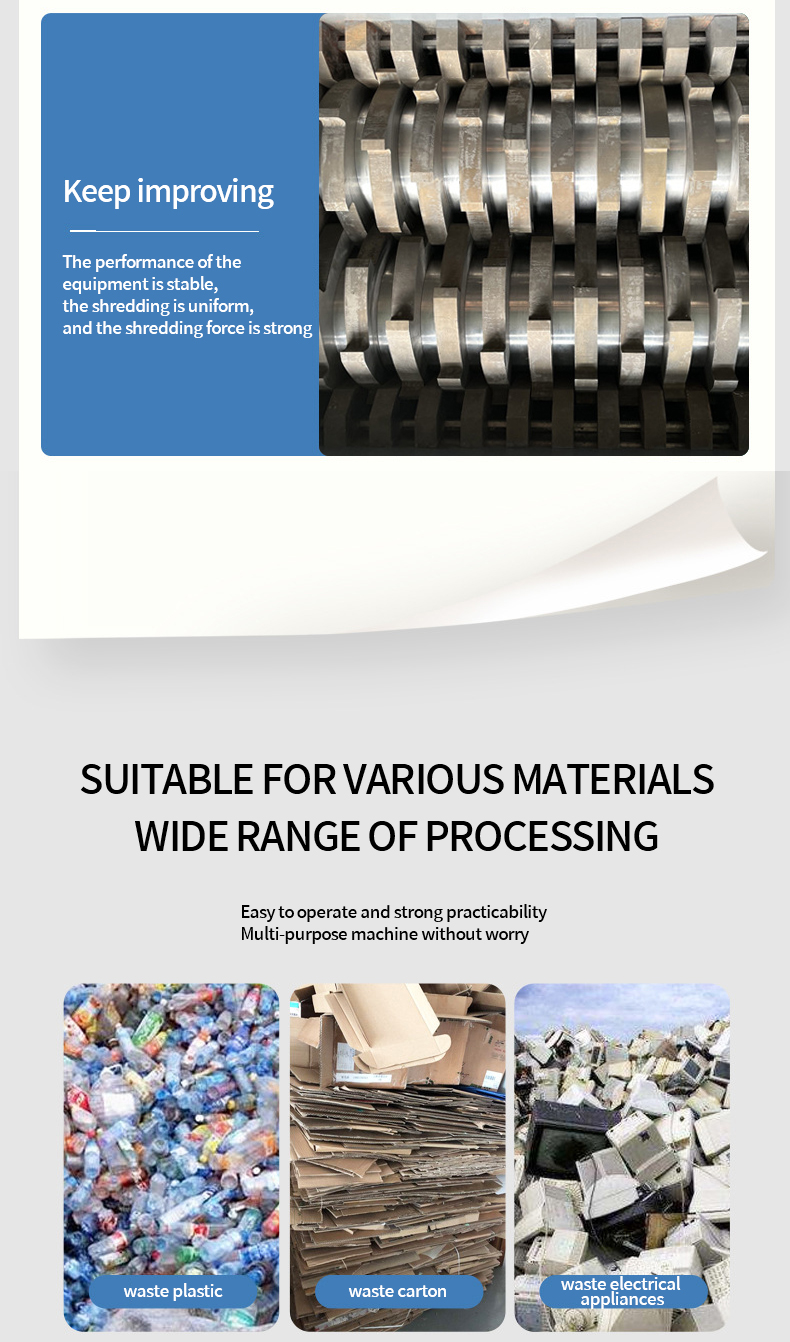

2. Diverse types of materials: It can handle various types of biomass materials, whether it is waste generated in agricultural production or branches and wood chips left over from forestry processing, which can be crushed by biomass pulverizers to achieve resource recycling.

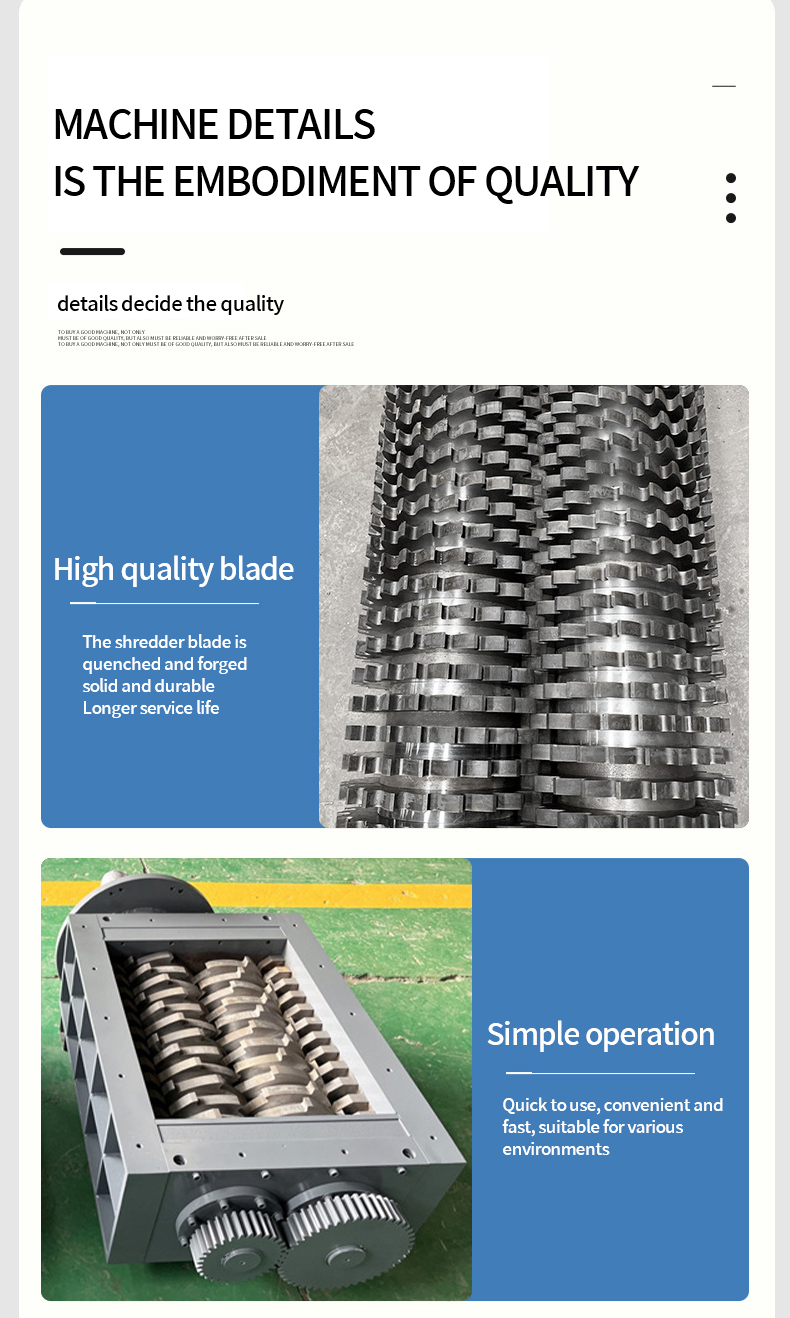

3. High crushing efficiency: With advanced crushing technology and structural design, a large amount of biomass materials can be crushed into the required particle size in a short time

4. Continuous operation capability: It has good stability and reliability, can run continuously for a long time, and meet the needs of large-scale production.

5. Large crushing ratio: It can crush larger-sized biomass materials into smaller particles, with a high crushing ratio, which can fully meet the requirements of biomass particle size in different application scenarios.

6. High degree of automation: Many biomass pulverizers are equipped with automatic control systems, which can realize automatic feeding, crushing, discharging and other operations, greatly reducing the labor intensity of operators. The operator only needs to perform simple settings and monitoring to ensure the normal operation of the crusher.

7. Low energy consumption: The use of efficient power system and optimized crushing structure can reduce energy consumption while ensuring the crushing effect. Compared with traditional crushing equipment, the biomass crusher has lower energy consumption, meets the requirements of energy conservation and environmental protection, and can save energy costs for users.

Biomass grinder is an advanced mechanical equipment specially designed for crushing various types of biomass materials. It plays a key role in many fields such as biomass energy utilization, organic fertilizer production, feed processing, etc. It can convert biomass raw materials of various shapes and large volumes into finely crushed materials with uniform particle size that meet the requirements of subsequent processing, providing a strong guarantee for the efficient utilization of biomass resources.

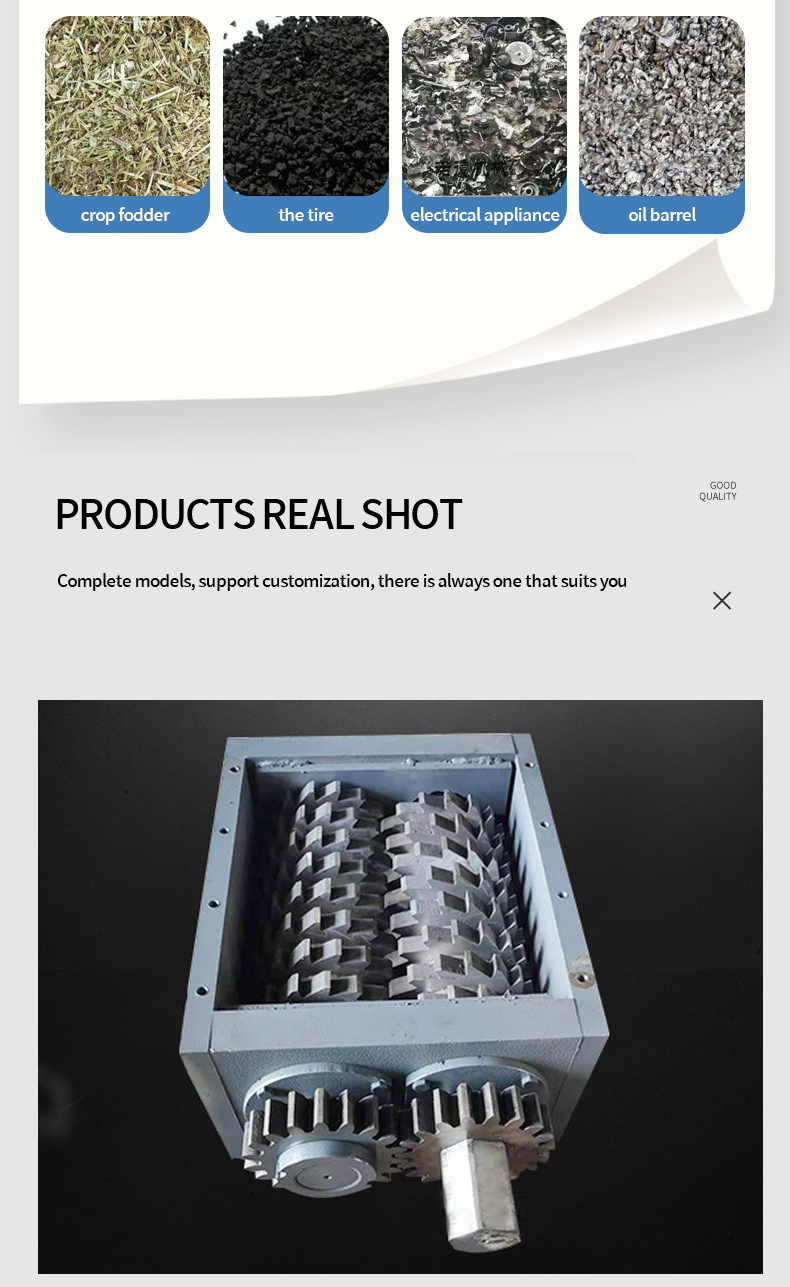

model number: EB300*200, EB400*200, EB500*250

motor: 3KW-4, 4KW-4, 7.5KW-4

reducer: JKA77, JKA87, JKA97

electric control cabinet: PLC protection system, PLC protection system, PLC protection system

input rotational speed: 16 rev/min, 17 rev/min, 15 rev/min

input torque: 1696Nm, 2176Nm, 4574Nm

input shaft diameter: Ф50, Φ60, Φ70

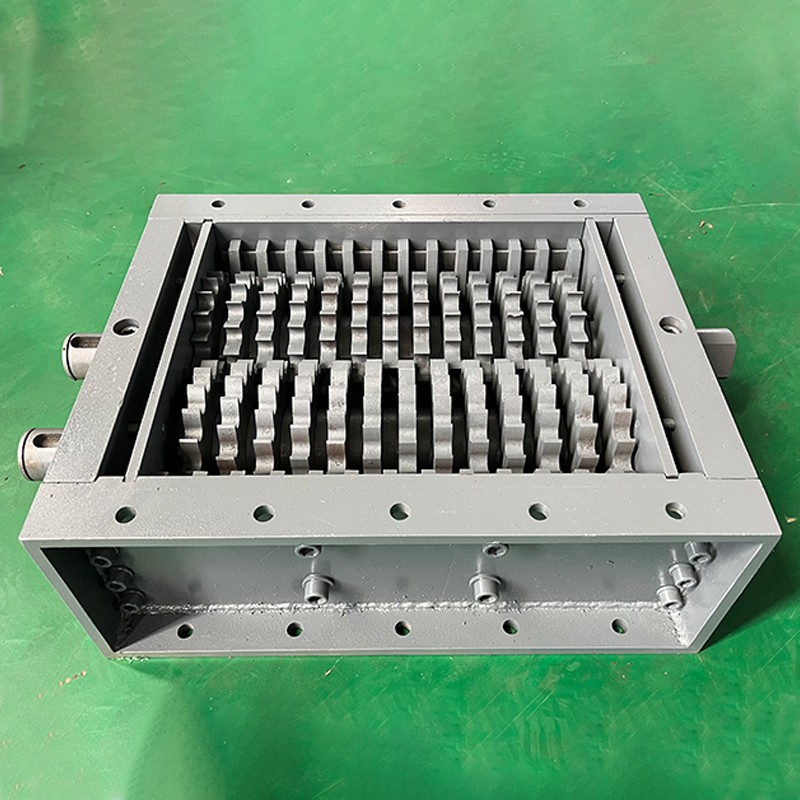

blade specifications: Φ180*12, Φ180*15, Φ200*20

blade quantity: 24 tablets, 26 tablets, 25 tablets

Feeding mouth size: 500*500*300, 500*600*300, 600*700*400

Machine Dimensions (L*W*H): 850*500*1300, 1000*500*1450, 1200*600*1550

Application scope: Light and thin metal products, plastic products, kitchen waste, etc.

This biomass pulverizer adopts advanced mechanical structure and power system, and has efficient pulverizing ability. Its unique tool design and rotor structure enable the material to be quickly cut, torn and impacted after entering the pulverizing chamber, thereby achieving rapid pulverization. Whether it is a large amount of crop straw, branches or other biomass waste, it can be pulverized in a short time, effectively improving production efficiency. Different models of equipment can produce from several cubic meters to dozens of cubic meters per hour, meeting the needs of production of different scales.

Application areas: Biomass energy production. In the production process of biomass pellet fuel and biomass briquette fuel, Biomass grinder is an indispensable equipment. It crushes biomass raw materials into suitable particle sizes, which is convenient for subsequent molding and drying. The produced biomass fuel can replace traditional fossil fuels.

Organic fertilizer processing. For organic fertilizer production enterprises, this grinder can crush and mix organic waste such as crop straw, livestock and poultry manure, and urban sludge to accelerate the fermentation process and improve the quality and production efficiency of fertilizers.

Feed industry. In the feed processing industry, Biomass grinder can be used to crush various grasses, crop straws and other roughage raw materials to make them easier for animals to digest and absorb. At the same time, some wood fiber raw materials such as fruit shells and branches can also be crushed and added to the feed after further processing to increase the nutritional value and taste of the feed and meet the feeding needs of different animals.

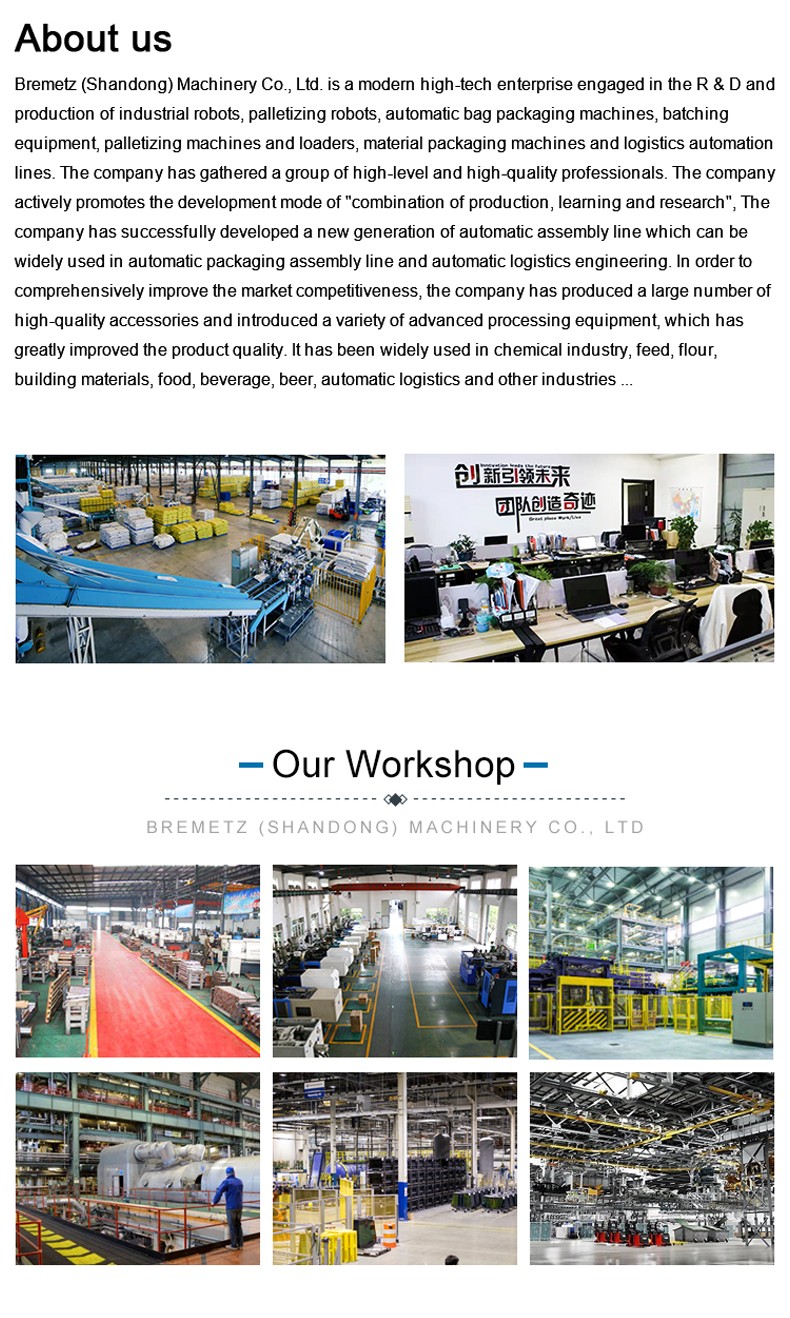

We have a professional installation team to provide door-to-door installation services for customers. During the installation process, we conduct comprehensive debugging of the equipment to ensure that all parameters of the equipment meet the requirements and can be well connected with upstream and downstream production equipment. At the same time, we provide on-site training for customers' operators, explain the operation methods, precautions and daily maintenance points of the equipment, and ensure that the operators can master the use of the equipment.