Fully automatic integrated grinding machine

1. Continuous work: It can run continuously for a long time without being disturbed by human factors, and maintain stable working efficiency and grinding quality. This is especially important for large-scale production or scenarios that require long-term continuous processing, which can significantly improve production efficiency and output.

2. Accurate setting of grinding parameters: Equipped with an advanced control system, it can accurately set and adjust the speed, time, strength and other parameters of grinding. This enables the machine to perform precise processing according to different materials and grinding requirements to ensure the consistency and high quality of the grinding results.

3. Intelligent monitoring and feedback: It has an intelligent monitoring function that can monitor the operating status of the machine and various parameters during the grinding process in real time. Once an abnormal situation occurs, the machine will automatically alarm and stop running to avoid further damage.

4. Compact structure: The grinding system, feeding system, discharging system, control system and other functional modules are integrated into an overall device with a compact structure and a small footprint.

5. Efficient collaborative work: The various functional modules cooperate with each other and work together to achieve fast and smooth transmission and grinding of materials. The integrated design also reduces the connection and debugging links between equipment, and improves the reliability and stability of the equipment.

6. Powerful grinding ability: It adopts high-performance grinding components and drive system, has strong grinding power and high speed, and can quickly and effectively grind materials into the required particle size.

7. High-fineness grinding: It can achieve high-fineness grinding effect, and can grind materials into very fine particles or powders, meeting the production process with high requirements for material fineness.

The fully automatic integrated grinding machine is a high-performance grinding equipment that integrates advanced technology, and is designed to provide efficient, accurate and convenient material grinding solutions for many industries. It perfectly combines automation technology, precision grinding technology and integrated design concepts, and can be widely used in mining, chemical industry, pharmaceutical, food processing and other fields to meet the grinding needs of different materials.

The use of high-quality grinding materials and advanced manufacturing technology makes the grinding parts have extremely high hardness, wear resistance and corrosion resistance. Whether grinding hard ores and metal materials, or soft food, medicinal materials and other materials, they can maintain good grinding effects and long service life. The special design and precise processing of the grinding wheel ensure that the material is subjected to uniform pressure and friction during the grinding process, so as to obtain high-quality ground products.

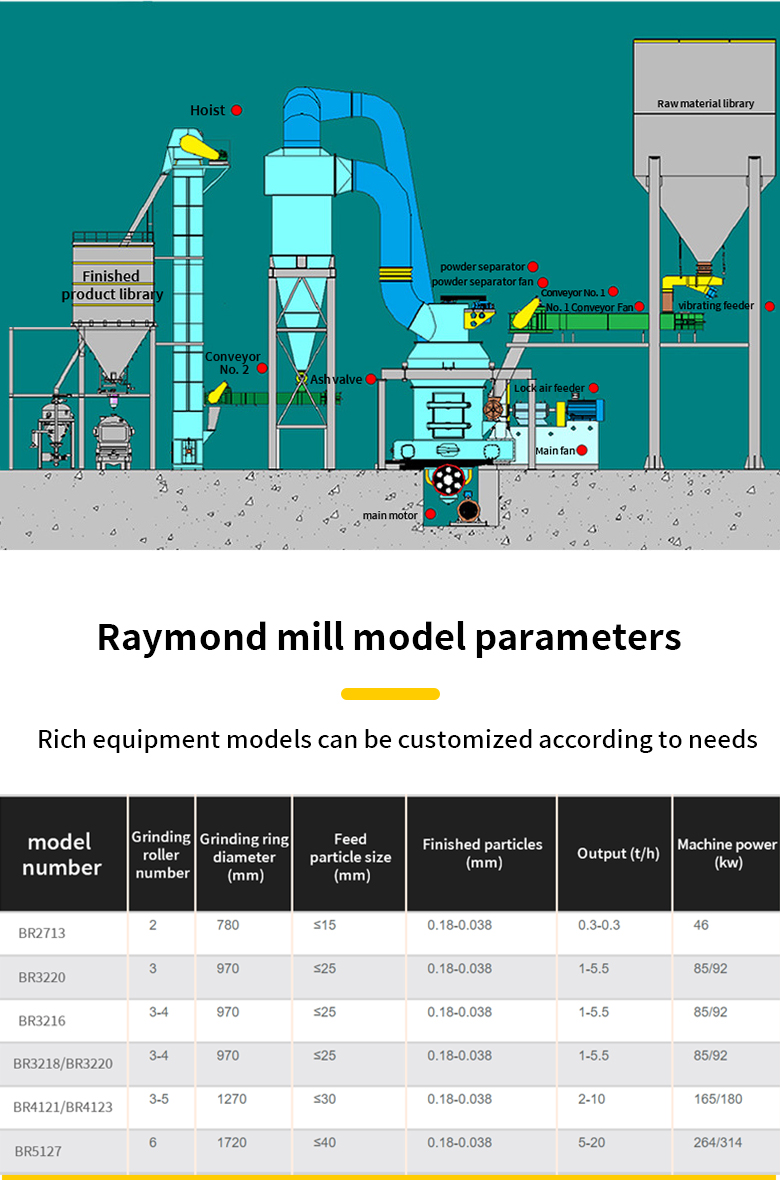

Model, number of grinding rollers, grinding ring diameter (mm), feed particle size (mm), finished particle size (mm), output (tons/hour), machine power (kw).

BR2713, 2,780, ≤15, 0.18-0.038, 0.3-0.3, 46.

BR3220, 3,970, ≤25, 0.18-0.038, 1-5.5, 85/92.

BR3216, 3-4,970, ≤25, 0.18-0.038, 1-5.5, 85/92.

BR3218/BR3220, 3-4,970, ≤25, 0.18-0.038, 1-5.5, 85/92.

BR4121/BR4123, 3-5, 1270, ≤30, 0.18-0.038, 2-10, 165/180.

BR5127, 6, 1720, ≤40, 0.18-0.038, 5-20, 264/314.

The equipment is equipped with complete safety protection devices, such as emergency stop button, overload protection device, protective door interlock, etc. The emergency stop button is located in an easy-to-operate position on the equipment. Once an emergency occurs, the operator can quickly press the button to stop the equipment immediately to ensure the safety of personnel and equipment. The overload protection device can monitor the load of the motor and grinding parts in real time, and automatically cut off the power supply when overload occurs to prevent the equipment from being damaged due to excessive load. The protective door interlock ensures that the protective door is closed when the equipment is running to prevent the operator from accidentally contacting the moving parts.

Application areas: In the mining industry, it is used for crushing and grinding of ores, and grinding the mined large pieces of ore into a particle size suitable for subsequent mineral processing, smelting and other processes.

In the chemical industry, in the processing of chemical raw materials, various plastics, rubbers, pigments, coatings and other raw materials are ground and refined. By accurately controlling the grinding fineness, the requirements of raw material particle size for the production of different chemical products can be met, and the product quality and performance can be improved.

In the pharmaceutical industry, it plays an important role in the crushing of Chinese medicinal materials and the grinding of Western medicine raw materials.

In the food processing industry, it is widely used in grain processing, spice grinding, coffee bean grinding and other links. In grain processing, wheat, corn, etc. can be ground into flour or other particle sizes required for processing.