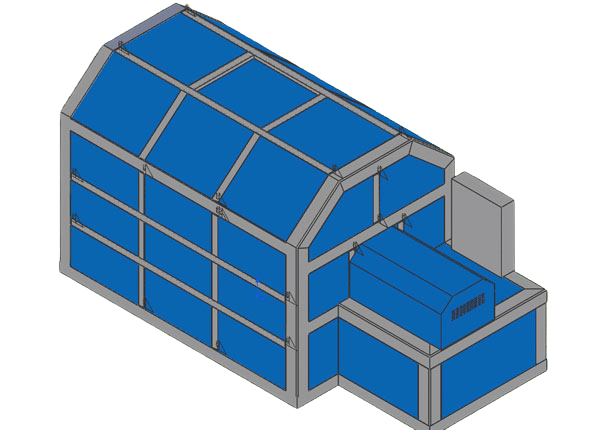

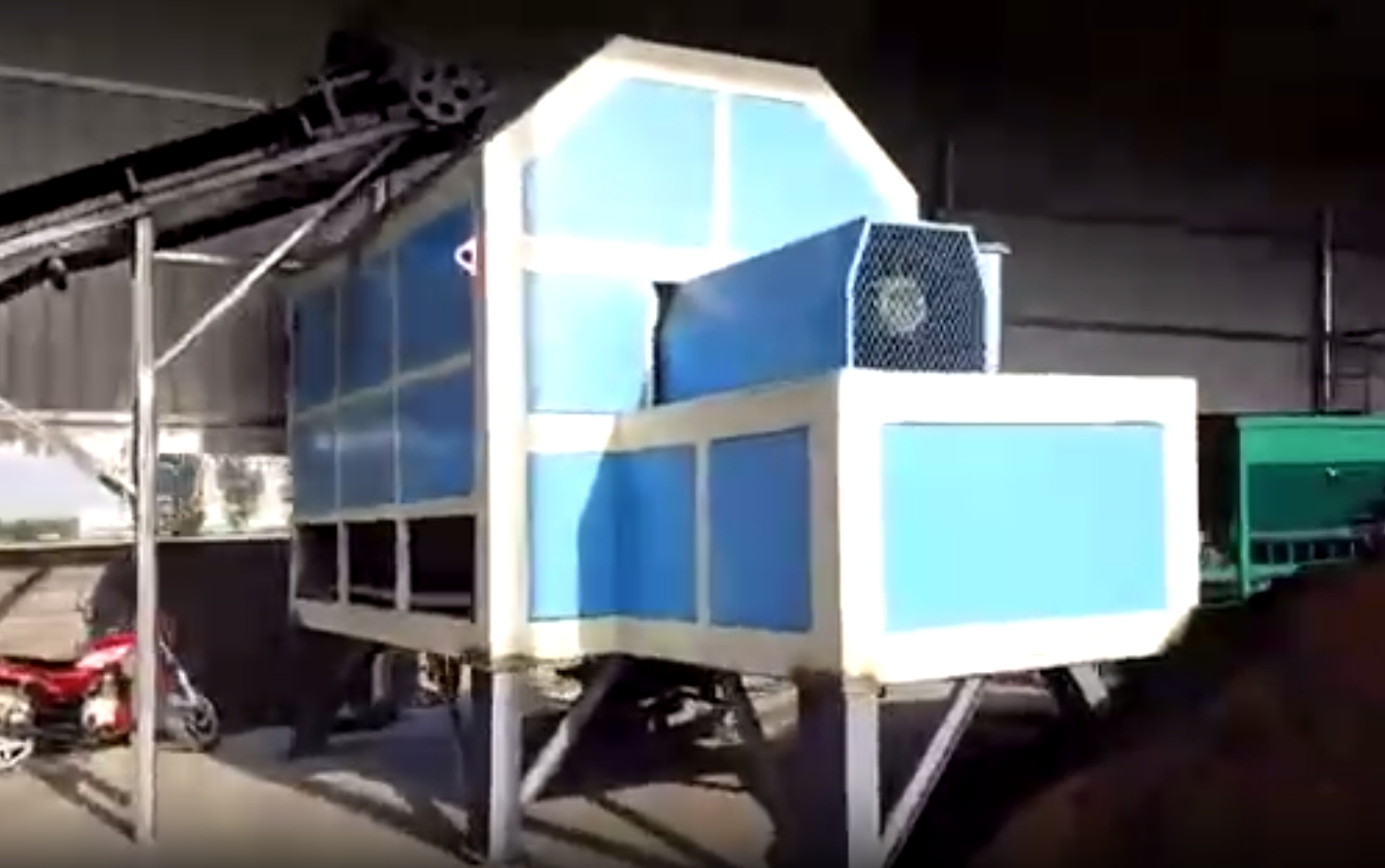

Horizontal fermenter

High temperature aerobic fermentation, the use of high temperature biological bacteria technology, low energy consumption, low operating cost; The equipment covers a small area, high degree of automation, one person can complete the fermentation process; Through biological deodorization equipment to achieve gas standard emission, no secondary pollution; The main thermal insulation design, auxiliary heating to ensure the normal operation of equipment in low temperature environment.

The horizontal fermenter is mainly an integrated sludge treatment equipment for high temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, for biological decomposition, so that it can achieve resource utilization. The horizontal fermenter is mainly used for high temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, and uses the activity of microorganisms to biodecompose the organic matter in the waste, so that it can achieve harmless, stable, reduced and resource utilization

The horizontal fermenter is mainly an integrated sludge treatment equipment for high temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, for biological decomposition, so that it can achieve resource utilization.

How it works:

The waste (livestock and poultry manure, kitchen waste, domestic sludge, etc.), biomass (straw and sawdust, etc.) and reflux materials are mixed evenly according to a certain proportion, so that the moisture content reaches the design requirements of 60-65% into the three-dimensional aerobic system, by adjusting the moisture and oxygen content of raw materials and temperature changes, so that the material is fully aerobic fermentation decomposition. The organic fertilizer fermenter controls the temperature between 55 and 60℃ through ventilation, oxygenation, stirring and other functions to achieve the temperature of material fermentation treatment. At this temperature, a large number of pathogens and parasites in the pile can be killed. At the same time, the deodorization system is used to carry out biological odor of the discharged gas to achieve the purpose of harmless treatment.