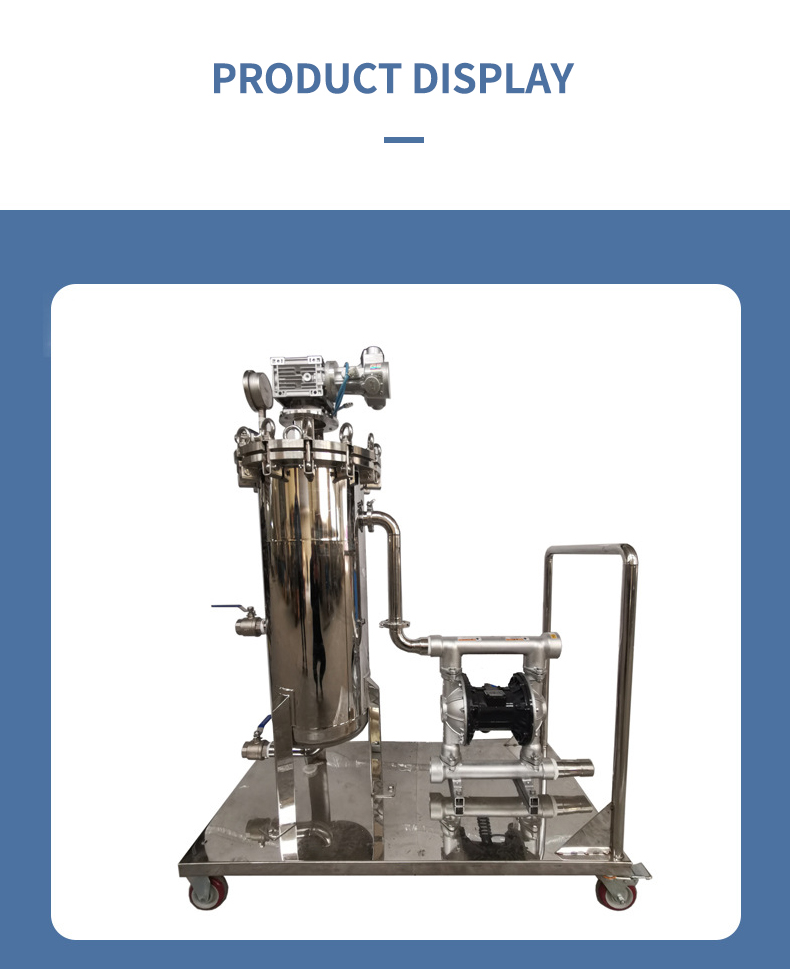

Organic fertilizer filter

1. High filtration precision: The organic fertilizer filter can accurately remove impurities, and its filtration precision can reach the micron level.

2. Large processing capacity: The equipment has strong processing capacity and can process several tons or even dozens of tons of organic fertilizer per hour.

3. Combination of multiple filtration methods: Some filters use multi-layer filtration or a combination of multiple filter media.

4. Improve the quality of organic fertilizer: By removing impurities, organic fertilizer filters can significantly improve the quality of organic fertilizer. Pure organic fertilizer has higher nutrient content and more uniform texture, which is beneficial to the absorption and growth of crops.

5. Comply with product standards: This filter can help organic fertilizer manufacturers ensure that products comply with national standards and industry specifications, and avoid product quality failures caused by excessive impurities and other issues.

6. Strong continuous working ability: The organic fertilizer filter is designed to operate continuously for a long time and can adapt to the continuous needs of organic fertilizer production.

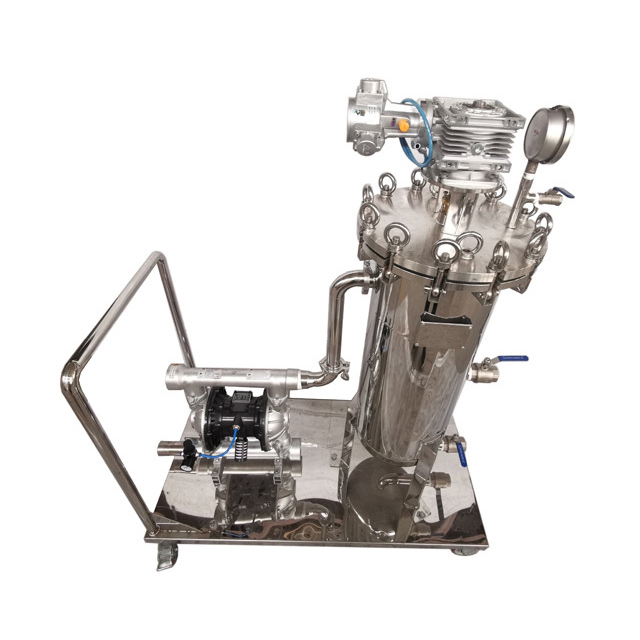

7. Durable components and structure: The key components of the equipment, such as filters, casings, motors, etc., are made of high-quality materials. The filter is usually made of corrosion-resistant, high-strength stainless steel or special fiber materials. The shell has good sealing and sturdiness, and the motor performance is stable and reliable.

The organic fertilizer filter is a high-efficiency filtration equipment specially designed for the organic fertilizer production industry. It plays a vital role in the production process of organic fertilizer, ensuring that the quality and purity of organic fertilizer meet high standards.

Organic fertilizer filters mainly work based on the principle of physical filtration. The core is to filter organic fertilizer through filter media with specific pore sizes, such as filter screens, filter cloths, etc. When organic fertilizer materials pass through the filter, impurities are intercepted on the surface of the filter media, while pure organic fertilizer passes smoothly, thus achieving the separation of impurities and organic fertilizer.

High-precision filtration: Organic fertilizer filters have amazing filtration accuracy, which can be accurate to the micron level. Some of our high-end models can effectively filter out impurities with a diameter of less than 50 microns, ensuring that the purity of organic fertilizer reaches an extremely high level. Whether it is tiny sand particles or imperceptible fibers, nothing can escape its sophisticated filtration system.

High throughput capacity: It excels in production efficiency, with an hourly processing capacity of several tons or even tens of tons. Whether it is a small organic fertilizer processing plant or a large industrial production base, it can easily cope with large-scale organic fertilizer filtration needs and ensure the efficiency and smoothness of the production process.

Application areas: organic fertilizer factories, bio-organic fertilizer manufacturing, urban organic waste treatment plants, industrial organic waste treatment centers, flower planting bases, gardening landscape companies, mine reclamation.

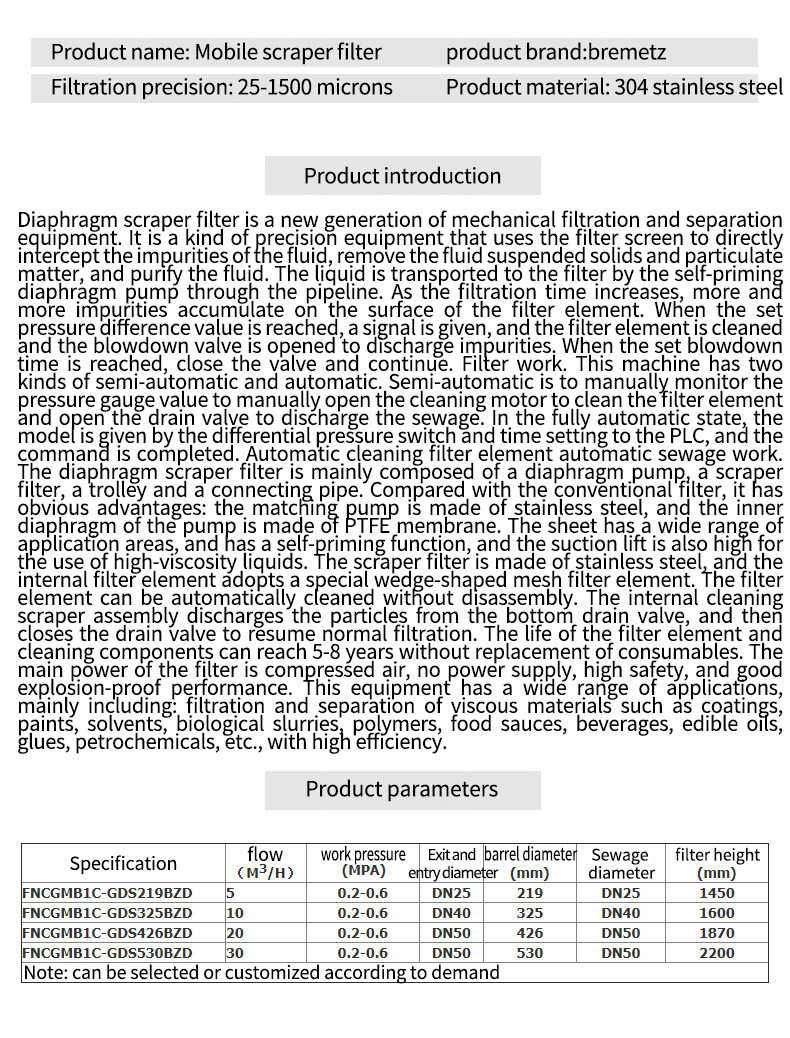

Product name: Organic fertilizer filter

Filtration precision: 25-1500 microns

product brand:bremetz

Product material: 304 stainless steel

Specification:FNCGMB1C-GDS219BZD

flow (M³/H):5

work pressure (MPA):0.2-0.6

Exit and barrel diameter entry diameter (mm):DN25,219

Sewage diameter:DN25

filter height(mm):1450

Continuous operation capability: Designed for long-term continuous operation, it can perfectly adapt to the continuity characteristics of organic fertilizer production. On large production lines, it can filter organic fertilizer continuously and stably, effectively reducing the number of production interruptions, greatly improving the overall production efficiency, and saving time and cost for enterprises.

Durable structure and components: The key components of the equipment are made of high-quality materials. The filter is usually made of corrosion-resistant, high-strength stainless steel or special fiber material to ensure that it will not be corroded by the chemicals in the organic fertilizer during long-term use, and can withstand the pressure and friction of the material. The outer shell has good sealing and firmness, which can effectively prevent material leakage and the intrusion of external impurities. The performance of power components such as motors is stable and reliable, providing a strong guarantee for the long-term stable operation of the equipment.

In short, organic fertilizer filters have become an indispensable key equipment in the organic fertilizer production industry due to their efficient filtration performance, stable operating characteristics, convenient operation and maintenance, and wide applicability. They have played an important role in improving the quality of organic fertilizers and promoting the sustainable development of agriculture.