Organic fertilizer production line

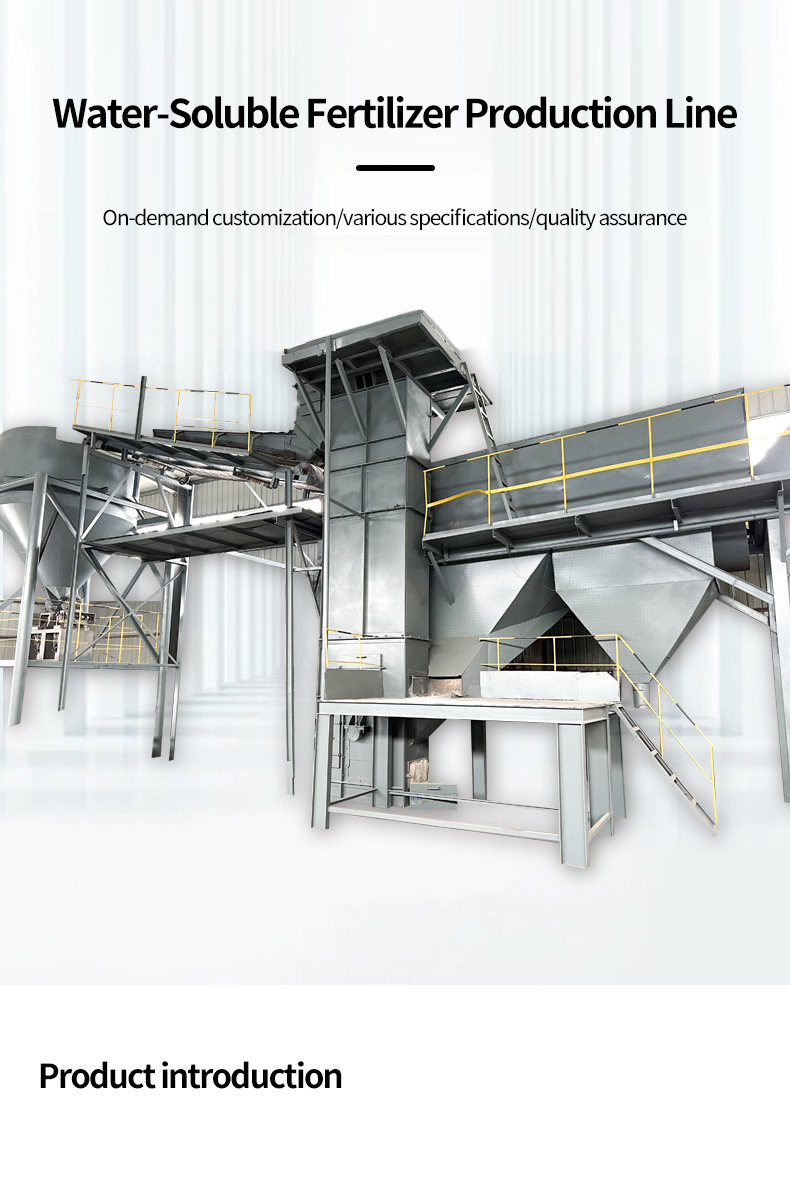

1. High-yield output: Equipped with high-performance equipment components, it has a large production scale capacity. Whether it is a small regional fertilizer production plant or a large industrial production base, there are suitable production line configurations to choose from.

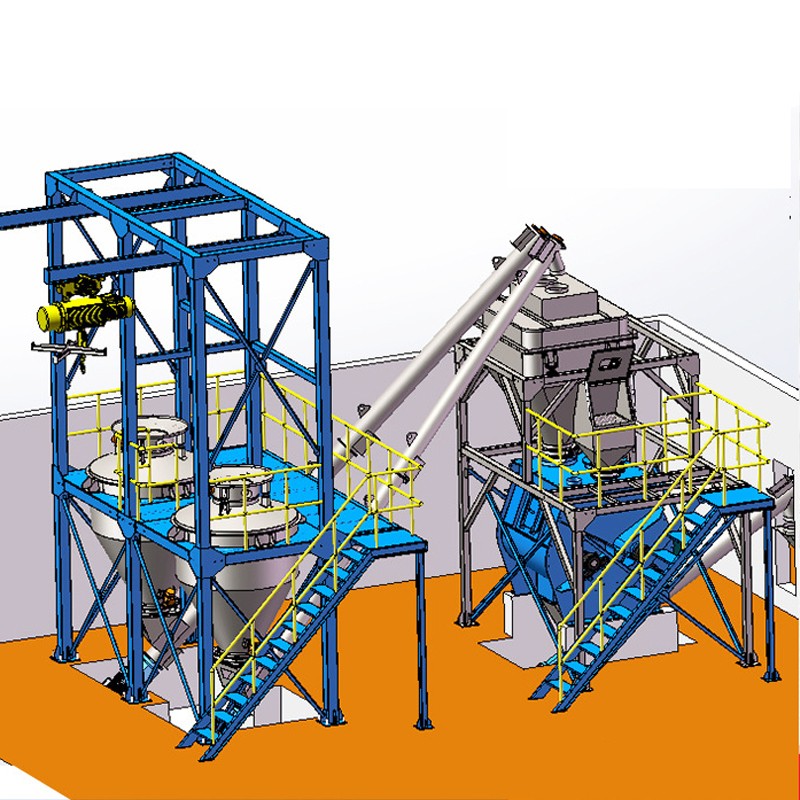

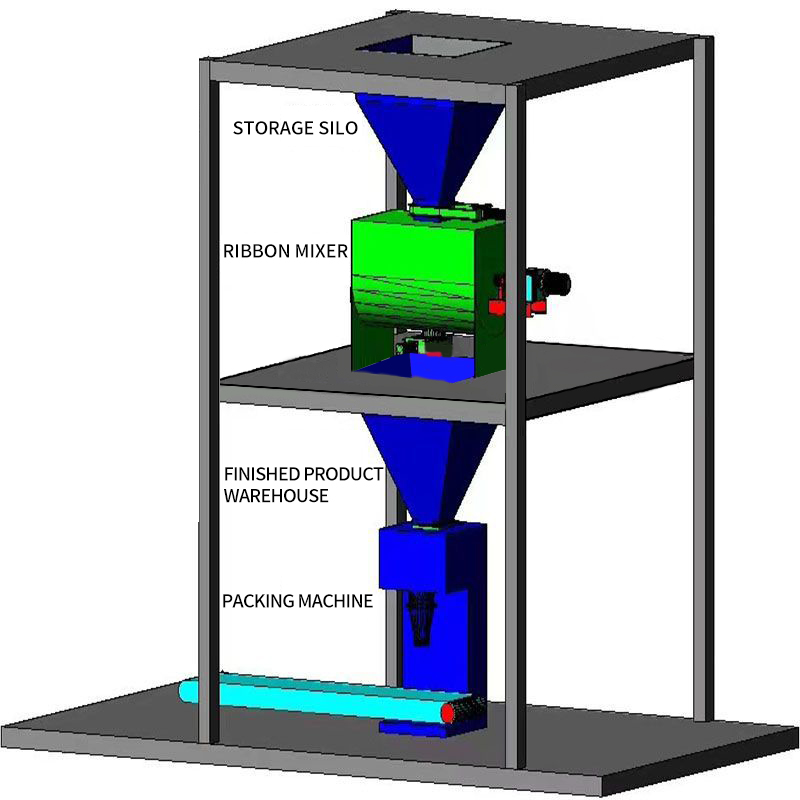

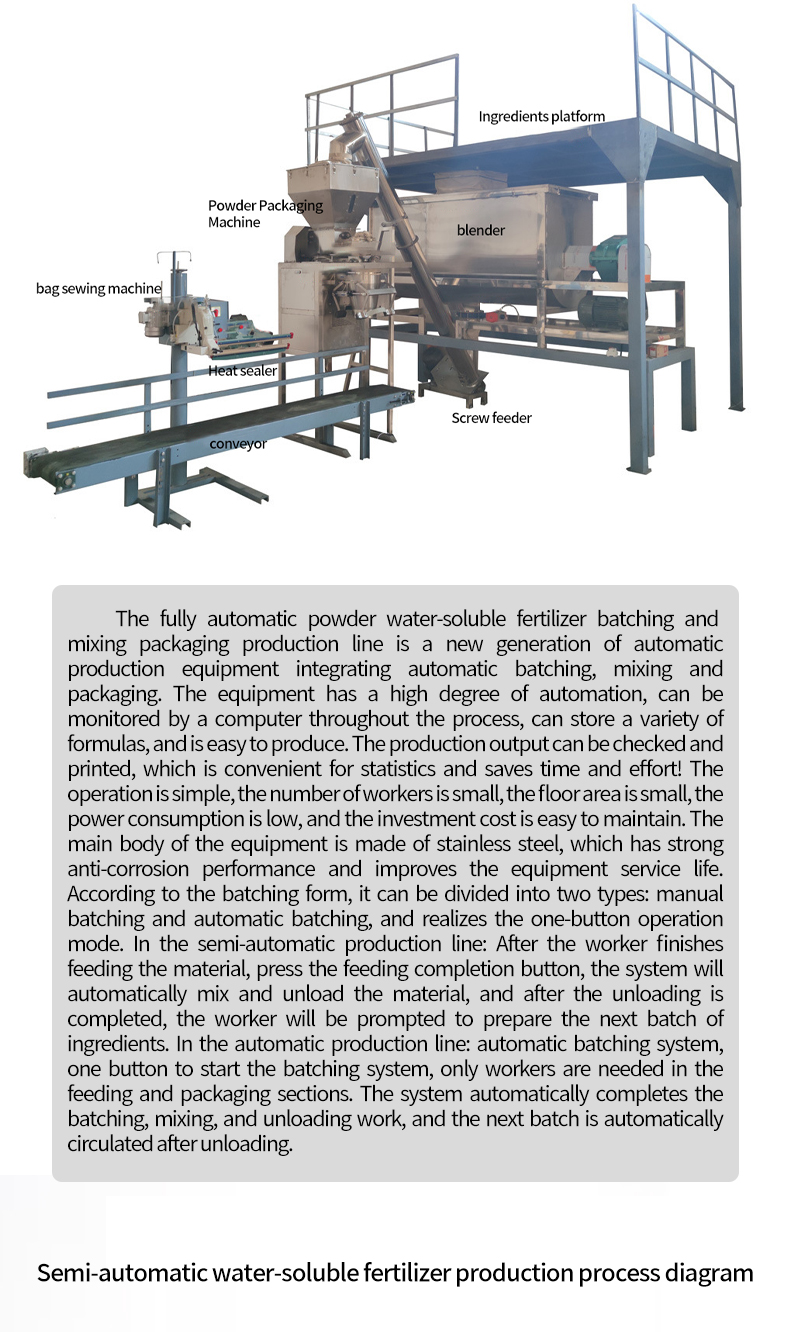

2. Precise batching and mixing: The production line has a precise batching system that can accurately control the proportion of various organic raw materials according to different fertilizer formula requirements. In the mixing and mixing process, an efficient mixer is used to ensure that the materials are fully and evenly mixed, ensuring the balance of organic fertilizer nutrients, and laying the foundation for the production of high-quality organic fertilizers.

3. Scientific fermentation process: It integrates advanced fermentation technology, including aerobic fermentation or anaerobic fermentation and other modes. Through the precise control of fermentation temperature, humidity, ventilation and other conditions, the role of microorganisms is used to make the organic materials fully decomposed.

4. Diverse granulation process selection: It has a variety of granulation processes, such as disc granulation, extrusion granulation, drum granulation, spray granulation, etc. The most suitable granulation method can be selected according to the different raw material characteristics and the market requirements for the shape, size and strength of fertilizer particles.

5. Automated production process: A highly automated operation is achieved, from the automatic delivery of raw materials, automatic metering of ingredients, to the automatic start and stop of each production link, without excessive human intervention.

6. High-quality equipment materials and processes: The equipment of the organic fertilizer production line is made of high-quality materials with good corrosion resistance, wear resistance and strength.

The organic fertilizer production line is a comprehensive production system that integrates a variety of advanced processes and equipment and is specifically used to produce organic fertilizers. It converts various organic wastes, such as livestock and poultry manure, crop straw, urban sludge, kitchen waste, etc., into nutrient-rich, safe and environmentally friendly organic fertilizers through a series of scientific processing steps to meet the needs of modern agricultural production for green and efficient fertilizers.

The production line first pre-treats the organic raw materials. For large pieces of materials, such as straw and branches, there are special crushers to crush them into suitable particle sizes for subsequent processing. For raw materials with high humidity, such as livestock and poultry manure, sludge, etc., drying equipment or moisture regulating devices can be used to make their moisture content reach an appropriate range to ensure that the materials can be smoothly processed in subsequent mixing, fermentation and other links.

Equipped with a high-precision batching system, the amount of various organic raw materials and additives can be accurately weighed according to different organic fertilizer formulas. Then these materials are fully mixed by a powerful mixer to ensure the uniform distribution of nutrients in the fertilizer. This precise batching and mixing process is a key step in producing high-quality organic fertilizers.

The entire production line adopts an automated control system with a programmable logic controller (PLC) as the core. Automated operation can be achieved in all links, from raw material transportation, batching, mixing, fermentation, granulation to packaging. The operator only needs to set the production parameters on the control interface, and the production line can automatically run according to the preset program. Automated control not only improves production efficiency, but also reduces human operation errors and ensures the stability of product quality.

In order to meet the production scale and needs of different users, the production line provides a variety of models and specifications of equipment to choose from. Whether it is a small organic fertilizer production workshop or a large industrial production enterprise, you can find the right equipment configuration. At the same time, the production line can also be customized according to the special requirements of the user, such as adjusting the production capacity of the equipment, changing the specifications of the fertilizer particles, adding special processing technology, etc.

We provide customers with comprehensive training services, including equipment operation methods, daily maintenance points, troubleshooting and handling, etc. The training methods include on-site training and online training. On-site training is carried out by professional technicians to demonstrate and explain the operation at the customer's site to ensure that the customer's operators can master the use and maintenance skills of the production line. Online training makes it convenient for customers to learn and review at any time by producing detailed training videos and tutorials.