Organic fertilizer crusher

1. Uniform drying: ensure that all parts of the material can be dried evenly, improve the quality stability of the product, improve production efficiency, and meet the needs of large-scale production.

2. Efficient energy utilization: the use of efficient heat source equipment and heat recovery technology can maximize the use of energy, reduce energy consumption, and save operating costs.

3. Strong material adaptability: suitable for various types of organic fertilizer materials, as well as other organic waste, can be effectively dried through this equipment.

4. Flexible production scale: whether it is a small organic fertilizer production workshop or a large organic fertilizer production enterprise, you can choose an organic fertilizer dryer of appropriate specifications and models according to actual needs to meet the requirements of different production scales.

5. Simple operation: the equipment has a high degree of automation and a friendly operating interface. The operator can master the operation method of the equipment after simple training.

6. Convenient maintenance: the structure is relatively simple, and the main components are durable and not easy to damage. The daily maintenance work is relatively small and the maintenance cost is low.

7. Retain nutrients: the use of appropriate drying temperature and process can retain the nutrients and trace elements in the organic fertilizer to the greatest extent, ensuring the fertilizer efficiency and value of the organic fertilizer.

As a key equipment in the production process of organic fertilizer, organic fertilizer dryer plays an indispensable role. With its excellent performance, advanced technology and wide applicability, our organic fertilizer dryer provides customers with efficient, environmentally friendly and reliable drying solutions.

The advanced drying process can quickly dry high-humidity organic fertilizer materials to the ideal moisture content. Whether it is a large-scale production operation or a small-scale processing demand, the drying task can be completed in a short time, greatly improving production efficiency.

The unique drum structure design ensures that the material is fully tumbled and evenly heated during the drying process, avoiding local overheating or uneven drying, thereby ensuring the stability and consistency of product quality.

Equipped with high-precision temperature sensors and intelligent control systems, it can monitor and accurately control the temperature during the drying process in real time. Ensure that the drying operation is carried out under the best temperature conditions to retain the nutrients and microbial activity in the organic fertilizer to the greatest extent.

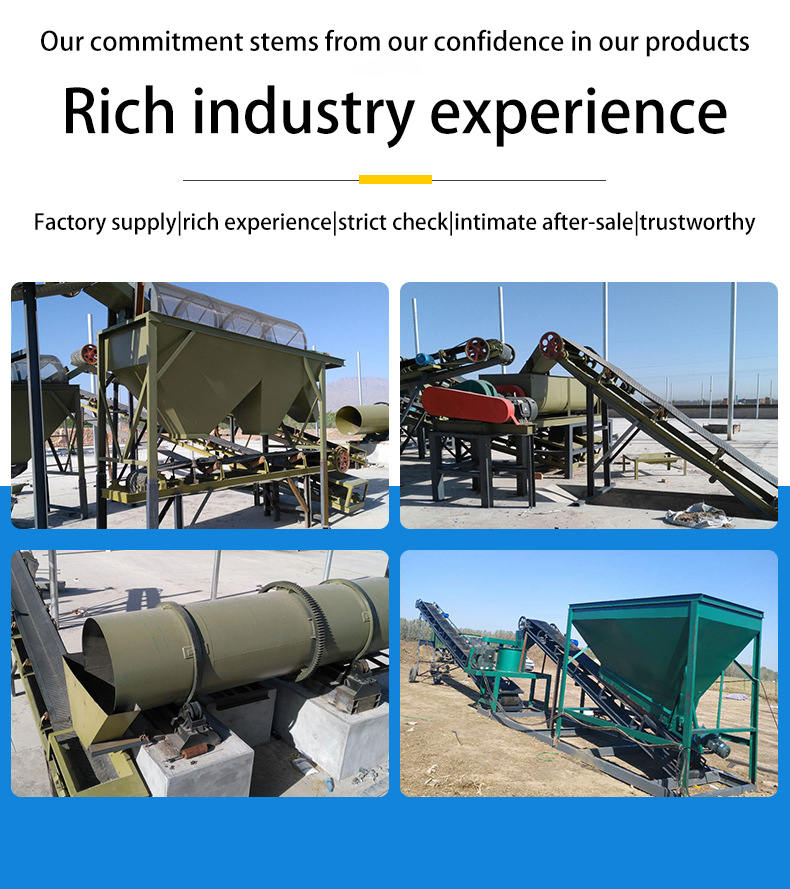

Our commitment stems from our confidence in our products Rich industry experience.Factory supply rich experience strict check intimate after-sale trustworthy.We have a professional technical team composed of senior engineers, who can provide customers with a full range of technical support and services. In terms of equipment installation and commissioning, operation training, maintenance and other aspects, our technicians will provide customers with timely, professional and thoughtful guidance and assistance to ensure that customers can correctly use and maintain the equipment and keep it in good operating condition at all times.

Our organic fertilizer dryer provides customers with a one-stop drying solution with its excellent performance, advanced technology, wide application fields and perfect after-sales service. Choosing our organic fertilizer dryer means choosing an efficient, environmentally friendly and reliable production method, which will add a strong impetus to the development of your business.

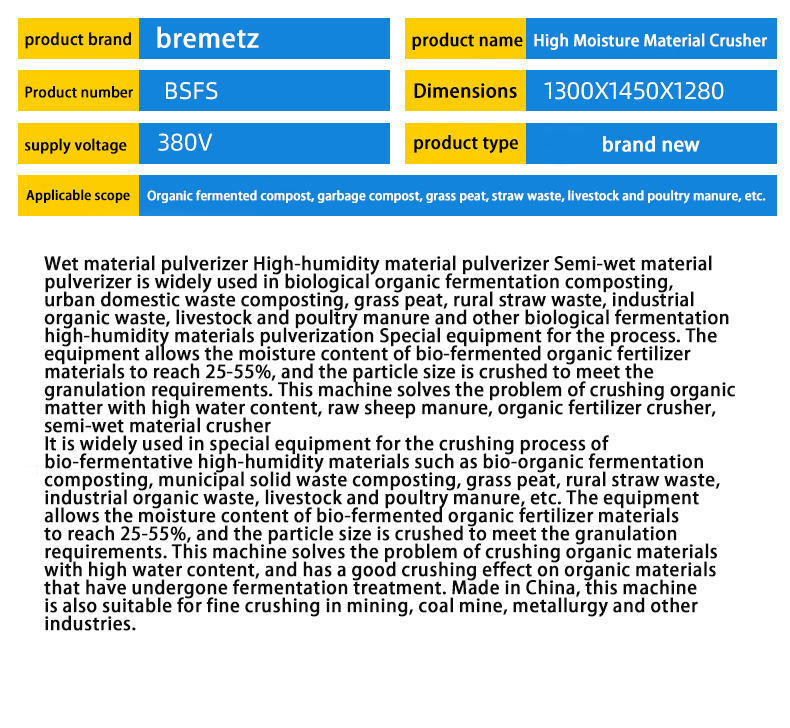

product name:High Moisture Material Crusher

Product number;BSFS

Dimensions:1300×1450×1280

supply voltage:380V

product type:brand new

Applicable scope:Organic fermented compost, garbage compost, grass peat, straw waste, livestock and poultry manure, etc.

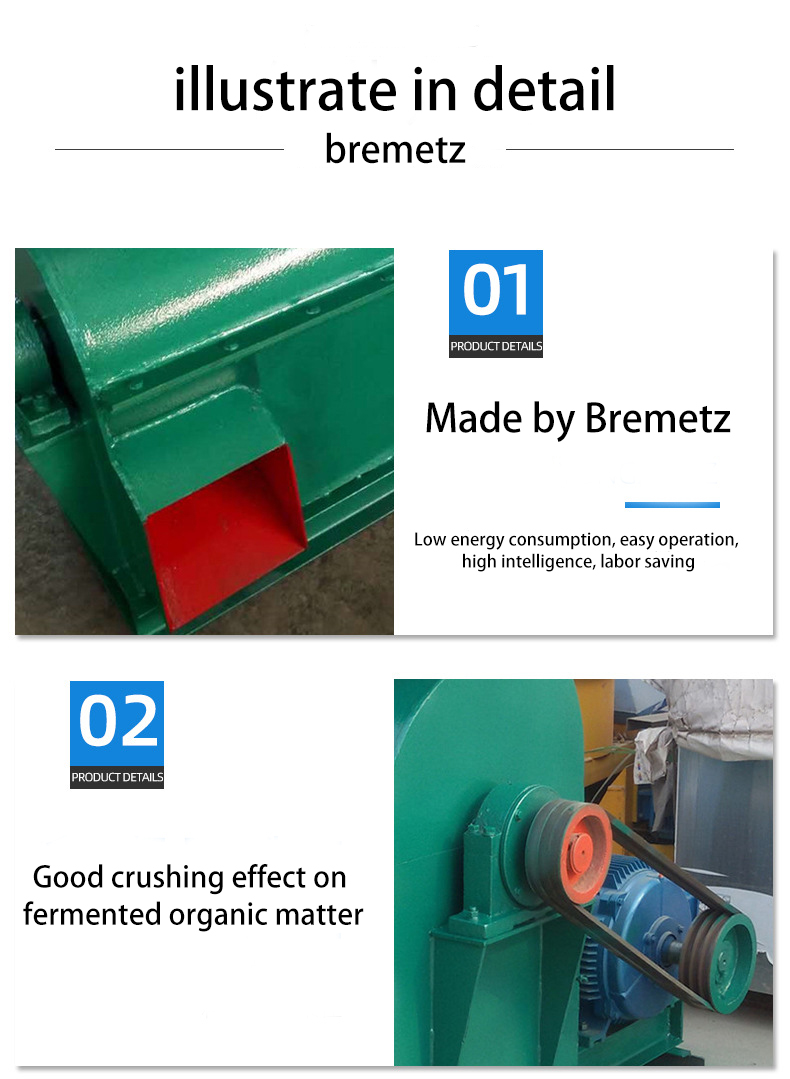

Wet material pulverizer High-humidity material pulverizer Semi-wet material pulverizer is widely used in biological organic fermentation composting, urban domestic waste composting, grass peat, rural straw waste, industrial organic waste, livestock and poultry manure and other biological fermentation high-humidity materials pulverization Special equipment for the process.This machine solves the problem of crushing organic materials with high water content, and has a good crushing effect on organic materials that have undergone fermentation treatment. Made in China, this machine is also suitable for fine crushing in mining, coal mine, metallurgy and other industries.