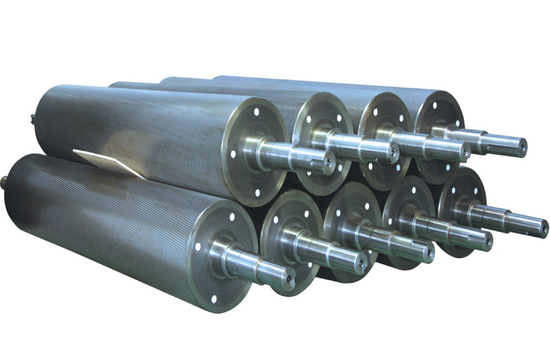

Crushing roller for crusher and shell peeling machine

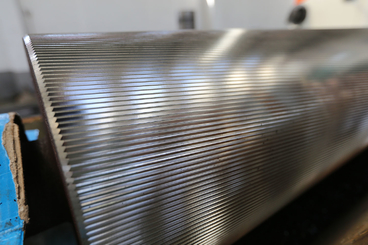

Crusher and shell peeling machine using crusher tooth roller has the following advantages: high efficiency crushing: Crusher tooth roller design is reasonable, can effectively break or peel the raw materials, improve production efficiency. Wear-resistant and durable: The crushing gear roller is made of wear-resistant material, which can withstand high intensity crushing work and extend service life. Precision machining: The crushing tooth roller has been precision machined, with good processing accuracy and stability, to ensure the crushing effect and product quality. Versatility: The crusher roller can be customized according to different raw materials and processing requirements, suitable for a variety of crushing and stripping processes. Low energy consumption: Crusher roller adopts advanced design and manufacturing technology, which can reduce energy consumption and save production costs. Easy maintenance: The crusher roller is simple in structure, easy to maintain and clean, reducing equipment failure and downtime.

Crusher roller is suitable for crusher and sheller and other equipment, with different specifications and models to choose from. The crushing gear roller is made of wear-resistant material, which can withstand high intensity crushing work and extend service life. After reasonable design, the crushing tooth roller can effectively break or peel raw materials and improve production efficiency. After precision machining, the crushing gear roller has good processing accuracy and stability to ensure the crushing effect and product quality. Crusher rollers can be customized for different raw materials and processing requirements and are suitable for a variety of crushing and stripping processes. The crusher roller is simple in structure, easy to maintain and clean, reducing equipment failure and downtime. Crusher and sheller using crusher roller products have the advantages of high efficiency, wear resistance, precision, multi-function, low energy consumption and easy maintenance, which can meet different industrial production needs and improve production efficiency.

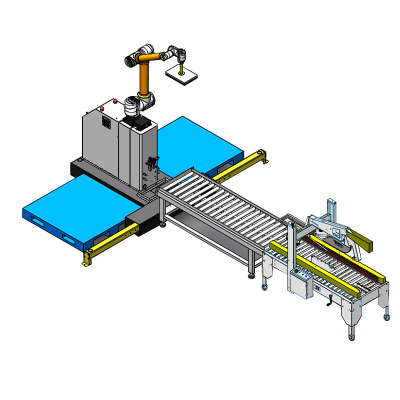

How it works:

The raw material enters the crushing tooth roll area of the crusher or sheller through the feed port. The crushing roller begins to rotate, trapping the material between the two rolls. When the tooth roll is turned, the material is squeezed, torn and broken, or the shell is stripped. Due to the design and movement of the crushing tooth roller, the raw material is broken or stripped to obtain the required particle size or remove the shell to achieve the desired processing effect. The material after crushing or stripping is discharged through the discharge port and goes to the next processing link or collection. The working principle of the crushing tooth roller is through the rotation of the tooth roller and the design shape, the raw material is sandwiched between the two tooth rollers, and after extrusion, tearing and crushing, or stripping the shell, the crushing or stripping of the raw material is achieved. This working principle can efficiently handle raw materials, improve production efficiency, and is suitable for a variety of industrial production scenarios.