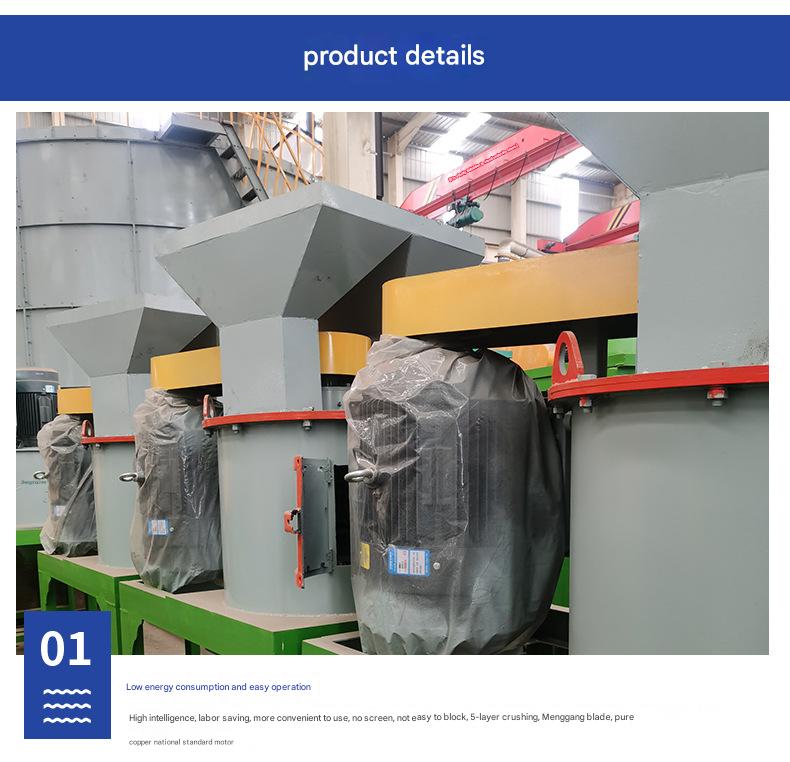

Customized organic fertilizer vertical crusher

Advantages of organic fertilizer vertical crusher: The inner wall of the machine casing is lined with polypropylene board, which alleviates the problem of sticking to the wall and difficult cleaning. The chain cutter head is made of special steel, which can effectively improve production efficiency. This machine has the characteristics of reasonable structure, easy operation and strong applicability.

The advantages of organic fertilizer vertical chain crusher are mainly reflected in the following aspects:

1. Made of high-strength materials, it has strong wear resistance and long service life;

2. The unique crushing tool design can achieve rapid crushing effect;

3. It is equipped with an advanced air circulation system to ensure that the temperature of urea raw materials is effectively controlled during the crushing process;

4. It adopts an automated control system, which is simple and convenient to operate and maintain;

5. It has complete environmental protection measures to meet national and regional environmental protection requirements.

The advantages of organic fertilizer chip crusher are mainly reflected in the following aspects: (1) Simple and reasonable structure, low operating cost. Utilizing the principle of stone hitting stone, wear is small.

(2) High crushing rate and energy saving.

(3) With fine crushing and coarse grinding functions.

(4) Little influence by the moisture content of the material, the moisture content can reach about 8%.

(5) The working noise is lower than 75 decibels (db level), and there is less dust pollution.

(6) Suitable for crushing medium-hard and extra-hard materials.

(7) The product is cubic, with high stacking density and minimal iron pollution.

(8) The impeller self-lining has little wear and easy maintenance

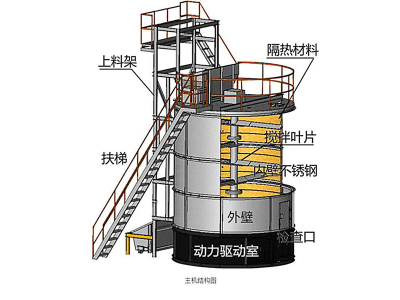

Vertical crusher is a kind of non-screen, adjustable fine crushing equipment, which is optimized and designed based on the advanced fine crushing equipment at home and abroad. It is one of the mainstream equipment widely used in mineral processing equipment. It can be used for final crushing of various materials such as limestone, cement clinker, mixture, gypsum, coal gangue, slag, copper ore, iron ore, etc. It is also one of the most commonly used crushing equipment in the compound fertilizer industry. It is suitable for crushing raw materials and return materials. It has strong adaptability to materials with high moisture content, is not easy to be blocked, and has smooth material discharge.

Our company produces vertical chain crusher. After technical improvement, the configuration and quantity of hammers have been improved to achieve better material crushing effect, the angle setting of the feed port has been improved to prevent material sticking at the feed port, the outlet setting has been improved, and the air outlet has been increased. When the dust is large, the dust can be pumped away to reduce dust pollution in the production workshop. The vertical chain crusher has an allowable moisture value of 25-50 for biological fermentation organic fertilizer materials, and the crushing particle size meets the granulation requirements. The crushing degree can also be adjusted within a certain range according to user needs.

The permissible moisture content of the bio-fermented organic fertilizer material in this pulverizer is 25-50, and the crushing particle size meets the granulation requirements. Through the reverse rotation of the two shafts, the material is sandwiched between the two rotating shafts, and the material is crushed under the action of axial force and extrusion force. At the same time, due to the reverse rotation of the two shafts, the material generates eddy currents in the equipment, thereby improving the crushing efficiency of the material. There are two levels of crushing, upper and lower, and two sets of rotors connected in series. The material crushed by the hammer of the upper rotor is immediately crushed again by the hammer of the lower rotor rotating at high speed, and the crushing effect is achieved by mutual crushing. There is no screen grate bottom, and there is no strict requirement for the moisture content of the material. There is no problem of sticking to the screen plate, and there is no problem of fine powder not being removed in time and repeated crushing; the crushing efficiency is high, and there is no ineffective wear of the hammer; the high-alloy wear-resistant hammer does not need to be repaired after wear, and can be moved and used repeatedly, and one pair of hammers can be used as three pairs. The crushing particle size can also be adjusted within a certain range according to user needs. Chicken manure crusher, cow dung crusher, organic fertilizer crusher are ideal machines for fertilizer production and processing units. Our company's products: organic fertilizer equipment, organic fertilizer production line, biological organic fertilizer equipment and other complete sets of compound fertilizer equipment, since the launch, have been well received by customers.

The products produced by the organic fertilizer vertical crusher are made of chicken, pig, cow dung, organic matter, urban garbage, and sludge as raw materials, without any chemical components, and chickens and pigs have poor digestion ability and can only consume 25 of the nutrients, while the other 75 nutrients in the feed are discharged with feces, so that the dry finished product contains nitrogen, phosphorus, potassium, organic matter, amino acids, protein and other components. The organic fertilizer granulator has created economic benefits for the enterprise and contributed to human environmental protection projects. It has a grinding effect on hard materials such as glass, ceramics, bricks, gravel, sludge, straw, rice husks, etc. in urban domestic garbage organic fertilizer to achieve the effect of use. The whole machine has a reasonable structure, easy installation and high energy saving. It is widely used in urban domestic waste, wine lees, mushroom residue, Chinese medicine residue, etc. It is the crusher model you choose. This machine shortens the process flow, reduces equipment investment, and saves operating costs for organic fertilizer and compost production. It is an ideal machine for fertilizer production and processing units.