Organic feed production line

1. Extensive raw material processing capabilities: The organic feed production line can process a variety of organic raw materials, whether plant or animal raw materials, the production line can convert them into high-quality organic feed through reasonable pretreatment and processing.

2. Resource recovery and recycling: Some agricultural and animal husbandry by-products that might have been discarded can be effectively recycled. The recycling of resources is realized, the pressure of waste on the environment is reduced, and the economic benefits of the entire agricultural and animal husbandry industry chain are improved.

3. Nutritional balance and stable quality: The production line is equipped with a precise batching system, which can accurately control the proportion of various raw materials according to the nutritional needs of different animals. In the mixing process, advanced mixing technology is used to ensure that various nutrients are evenly distributed in the feed, thereby ensuring the nutritional balance of the feed.

4. Improve feed digestibility and palatability: Through the optimized crushing process, the raw materials can be crushed to a suitable particle size, increasing the surface area of the feed, which is conducive to animal digestion and absorption.

5. Hygienic quality assurance: The organic feed production line pays attention to the hygienic quality of the feed. During the production process, multiple impurity removal and cleaning processes are set up to effectively remove impurities, foreign matter and harmful substances in the raw materials.

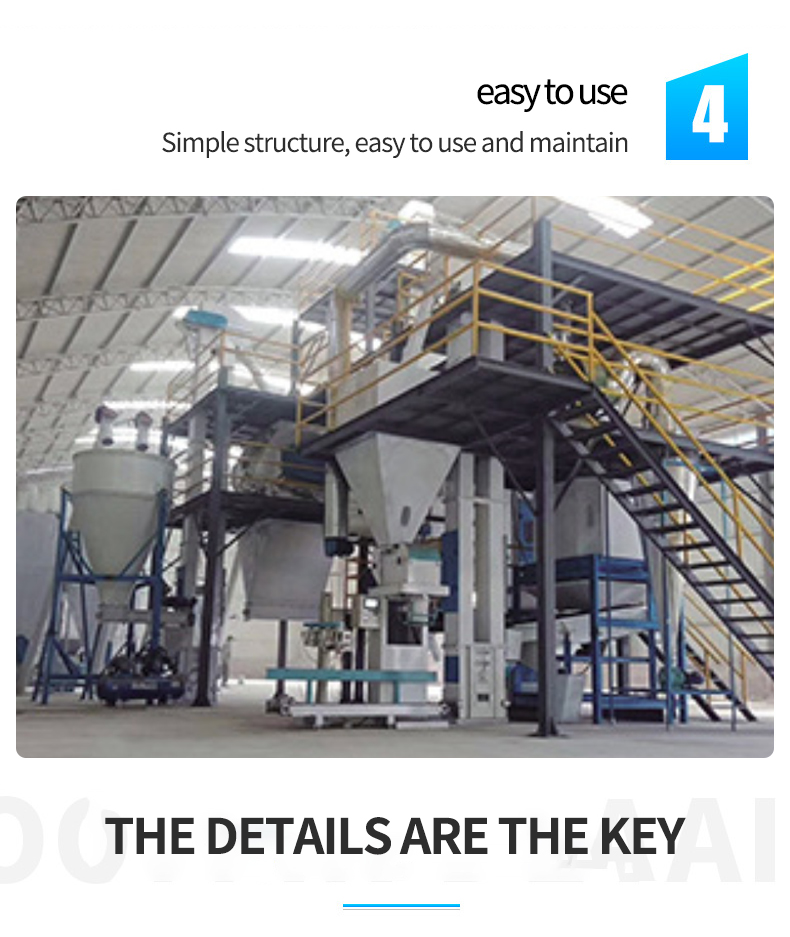

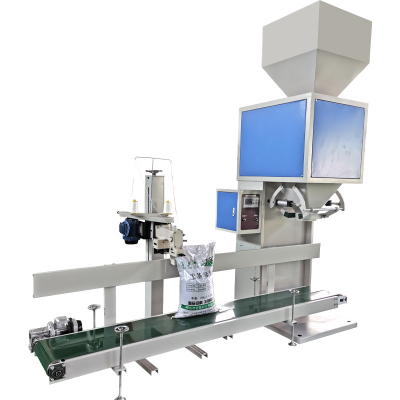

6. Efficient production capacity: The advanced production process and equipment combination are adopted to achieve efficient continuous production. A series of links from raw material transportation, crushing, mixing to granulation, drying, cooling, screening and packaging are closely connected, which reduces the pause and waiting time in the production process and greatly improves production efficiency.

7. Flexible process configuration: The production line is highly flexible and can flexibly adjust the feed formula, particle size, shape and processing technology according to market demand and user's special requirements.

The organic feed production line is a comprehensive system for producing high-quality organic feed. It integrates advanced processes and equipment to transform a variety of organic raw materials into nutritious, high-quality feed products that meet organic standards, meeting the nutritional needs of various farmed animals such as livestock, poultry, and aquatic products, while ensuring the environmental protection and efficiency of the production process.

The organic feed production line has a high-precision batching system that can accurately control the amount of various raw materials according to the nutritional needs of different animal species and growth stages. The advanced mixer uses a special mixing structure and technology to fully and evenly mix various raw materials in a short time, ensuring the balanced distribution of nutrients such as protein, carbohydrates, fat, vitamins, minerals, etc. in the feed, providing animals with a comprehensive and stable nutritional supply.

We have a variety of pelleting processes, including ring die pelleting, flat die pelleting, extrusion pelleting, puffing pelleting, etc. Different pelleting processes are suitable for different raw material combinations and feed product requirements. Ring die pelleting is suitable for large-scale production and can produce pellets with high density and moderate hardness; puffing pelleting can make the feed have better palatability and digestibility, especially suitable for aquatic feed. Through these processes, pellet feeds with shapes, sizes and densities that meet the requirements can be produced, improving the quality of feed and the feeding rate of animals.

The organic feed production line has a high-precision batching system that can accurately control the amount of various raw materials according to the nutritional needs of different animal species and growth stages. The advanced mixer uses a special mixing structure and technology to fully and evenly mix various raw materials in a short time, ensuring the balanced distribution of nutrients such as protein, carbohydrates, fat, vitamins, minerals, etc. in the feed, providing animals with a comprehensive and stable nutritional supply.

From raw material input to finished feed output, the production line is designed as a continuous production process. Each production link is closely coordinated, and materials are orderly transferred between equipment such as grinders, mixers, granulators, dryers, coolers, screeners and packaging machines through automated conveying equipment, avoiding production interruptions, greatly improving production efficiency, and ensuring a stable supply of feed output.

The entire production line adopts an automated control system with a programmable logic controller (PLC) as the core. The operator only needs to input production parameters on the operation panel, such as ingredient ratio, operating speed of each device, temperature control parameters, etc., and the production line can run automatically. Automated operation not only reduces labor intensity, but also reduces the impact of human errors on feed quality, ensuring the consistency of product quality.

We have established a complete after-sales service network, with after-sales service centers and spare parts warehouses across the country. We are equipped with professional maintenance engineers, who can respond to customers' maintenance requests in a timely manner when a customer's production line fails. Maintenance engineers can remotely guide customers to troubleshoot and repair problems through telephone and the Internet, and arrange door-to-door maintenance services in a timely manner for problems that cannot be solved remotely. At the same time, we provide customers with regular equipment maintenance advice and maintenance services to extend the service life of the equipment and ensure the long-term stable operation of the production line.