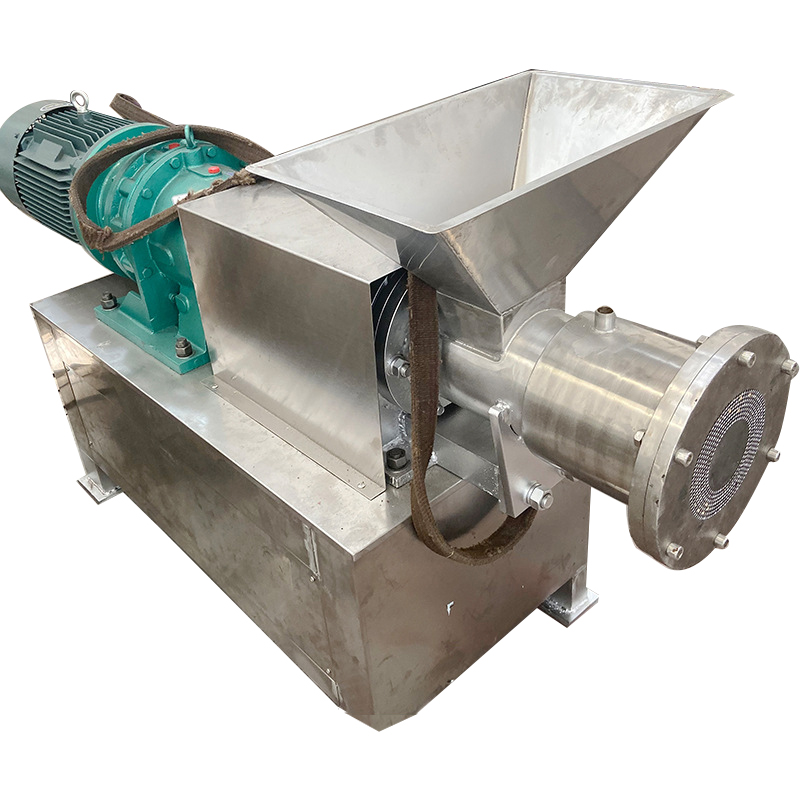

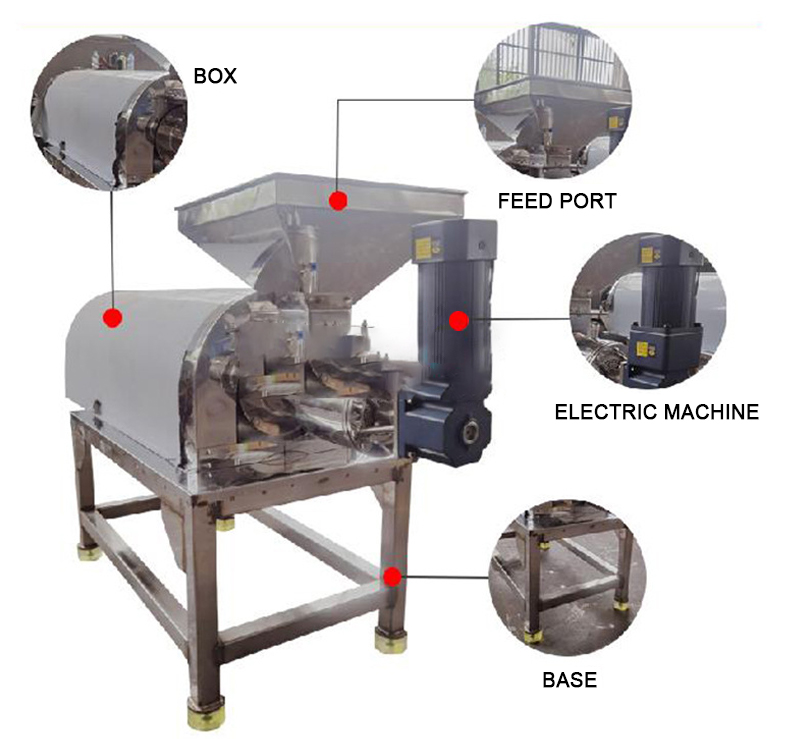

Double screw extruding granulator

The double screw extrusion granulator significantly strengthens the heat transfer, fluidization and extrusion process between materials, greatly optimizes the internal quality of pelletizing products, and thus obtains better granular products. Double screw extruding granulator has large production capacity, reliable performance and high molding rate. The double screw extruding granulator has a wide adaptability to materials, which is suitable for livestock and poultry manure, urban sludge, lees and bean residue. The working temperature produced in the pelleting process of the double screw extruded pelletizer is low and has no destructive effect on the material composition.

How it works:

Double screw extrusion granulator is the use of double screw countercurrent collision granulation technology, the use of pressure to agglomerate solid materials granulation process. Through a certain amount of water or steam, the main working method is wet granulation. After the basic fertilizer is moistened in the cylinder, the chemical reaction is full. Under a certain liquid phase condition, with the help of the rotating movement of the cylinder, the extrusion pressure is generated between the material particles and the agglomeration is formed into a ball.

Double screw extrusion granulator can be widely used in the fertilizer industry product granulation, used to extrude the material molding. Organic fertilizer granulation is an important process 'it not only determines the quality of granular fertilizer' but also relates to the size and cost of the product.