Large feed production line

1. Large-scale production capacity: Its output can reach several tons or even tens of tons per hour, which can stably and continuously supply sufficient feed products for large farms, many breeders and feed sales markets.

2. Efficient production process: It integrates advanced and efficient processing technology and automatic control system, and each production link is closely connected and coordinated, which minimizes the waiting time and material turnover time in the production process.

3. Accurate metering and batching: Equipped with high-precision metering equipment and automatic batching system, it can accurately measure and accurately batch various raw materials according to the preset feed formula.

4. High-quality mixing uniformity: It adopts professional mixing equipment with strong mixing and mixing capabilities, which can make various raw materials fully mixed and uniform in a short time.

5. Automated production operation: It almost covers the automated control of the entire production process from raw material feeding to finished product packaging, and only a few operators are required to monitor and simply adjust parameters through the human-machine interface in the central control room.

6. Intelligent management and monitoring: With the help of advanced Internet of Things technology, big data analysis and intelligent sensors, large-scale feed production lines can collect and analyze various data in the production process in real time.

Large feed production line is a highly integrated, automated feed processing system with large-scale production capacity, designed to meet the large demand for various feed products from large farms, many breeders and feed sales market. It covers the complete process from raw material input to finished feed output, integrating advanced mechanical manufacturing technology, automation control technology and feed processing technology.

It has strong production capacity and can meet the continuous supply demand of large-scale breeding enterprises, feed distributors, etc. for large quantities of feed products, which improves the scale benefits of feed production, reduces the production cost per unit product, and has greater price advantages and supply guarantee capabilities in market competition.

Strict quality control measures are implemented in every link from raw material metering and batching, crushing, mixing to granulation. Through high-precision metering equipment, advanced processing technology and precise parameter control, we ensure that each batch of feed produced meets high quality standards in terms of nutritional content, physical properties, etc., providing a stable and high-quality source of nutrition for farmed animals, which helps to improve the growth performance of animals and breeding benefits.

It has achieved highly automated production operations, reduced a large number of manual intervention links, reduced labor costs and improved production efficiency. In addition, with the help of an intelligent monitoring system, all kinds of data in the production process can be mastered in real time, which facilitates production management, fault warning and quality traceability, and improves the company's production management refinement and scientific decision-making.

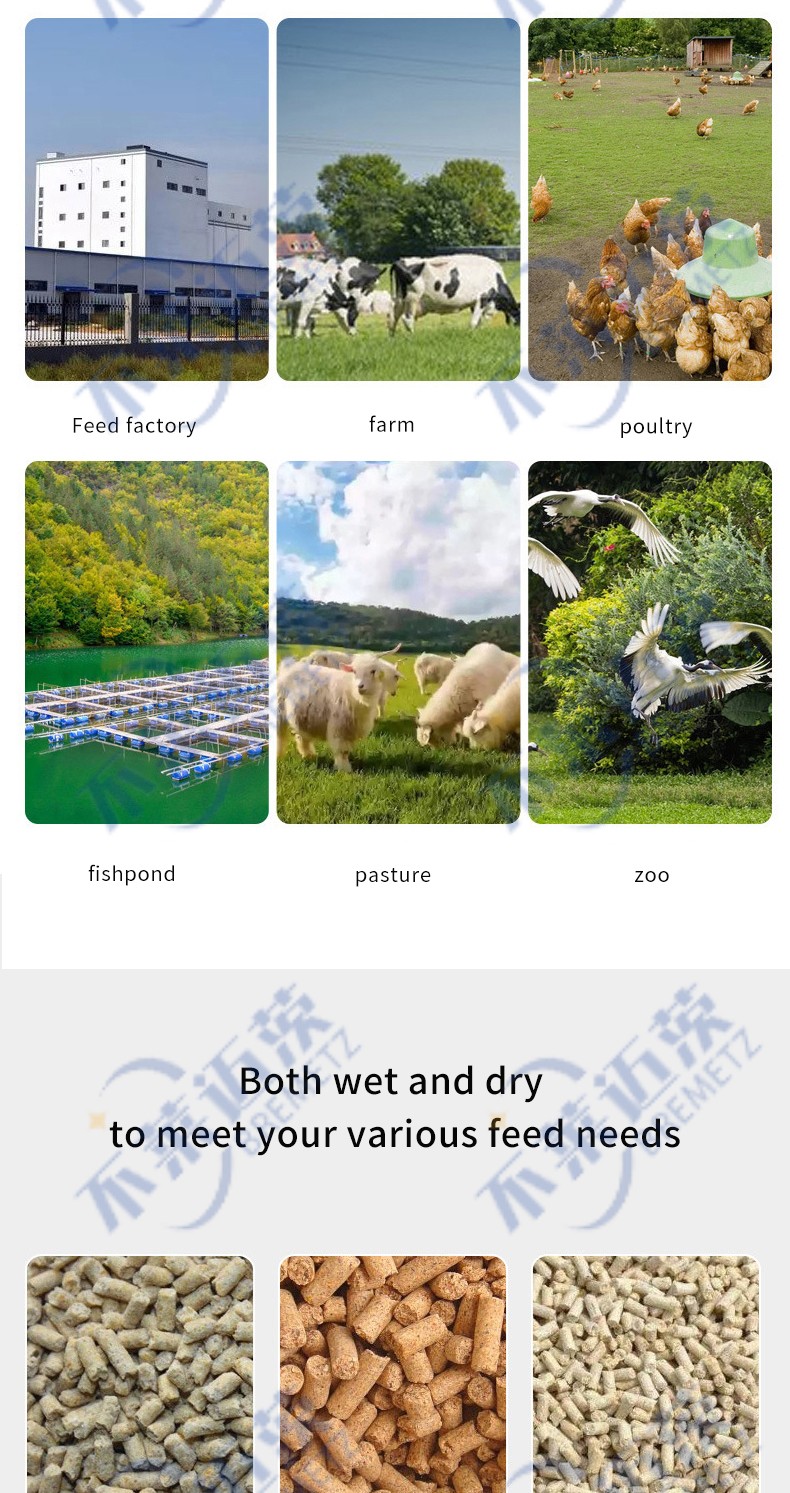

It can flexibly adjust the raw material formula and processing parameters to produce a variety of feed products suitable for different animal species (such as poultry, livestock, aquatic products, etc.), different growth stages (such as young, growing, adult, etc.) and different breeding purposes (such as meat, eggs, milk, etc.), to meet the market's diverse feed needs and broaden the company's product sales channels and market coverage.

In equipment selection and process design, we focus on efficient use of energy, adopt energy-saving equipment and optimized production processes to reduce energy consumption. At the same time, we are equipped with complete environmental protection facilities to effectively control the emission of pollutants such as dust and noise to achieve clean production, which is in line with the modern green development concept, helps enterprises establish a good social image and reduce environmental protection costs.

Applicable industries:

Animal husbandry: Provides full-stage feed products for livestock farms such as pigs, cattle, and sheep to meet their nutritional needs at different growth, fattening, and reproduction stages.

Poultry farming: Suitable for chickens, ducks, geese and other poultry farming, can produce high-quality feed that matches them, and ensure the egg-laying performance and growth rate of poultry.

Aquaculture: For aquatic animals such as fish, shrimps, and crabs, produce aquatic feed that meets their feeding habits and growth environment requirements.

Feed sales industry: Provides a large number of high-quality and diversified feed products to feed distributors, retailers, etc. to meet the diversified feed needs of different customer groups.

A professional technical team will provide on-site installation services, and carry out precise installation according to site planning and equipment requirements to ensure that the equipment on the production line is firmly connected, reasonably laid out, and runs smoothly. After the installation is completed, comprehensive debugging will be carried out to test each production link and adjust the parameters of each equipment to the best state.