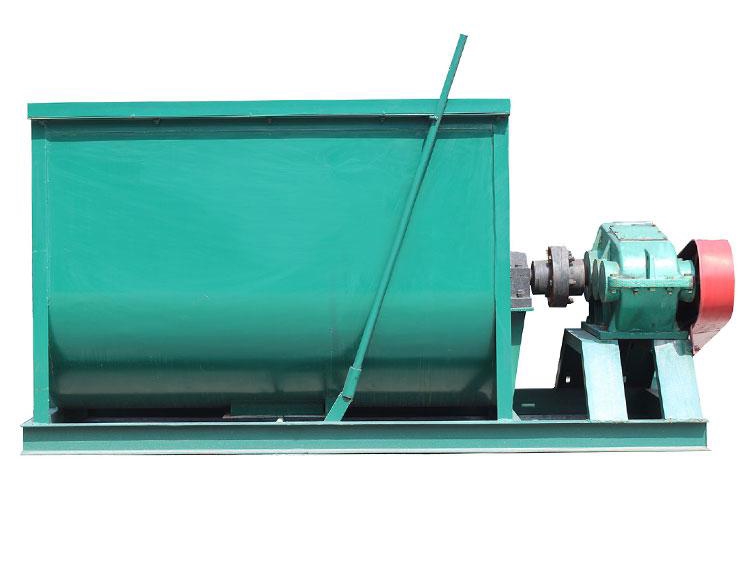

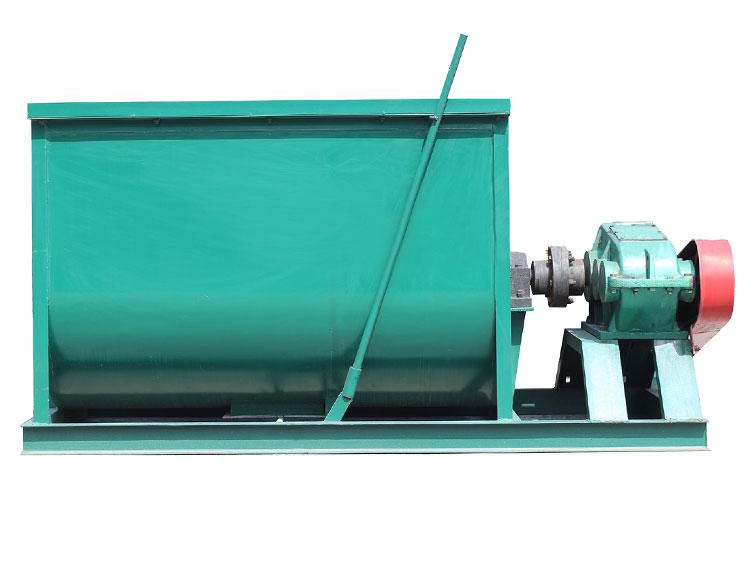

Fully automatic horizontal mixer

1. Easy operation: Just put the material into the mixer, set the relevant parameters, such as mixing time, mixing speed, etc., and start the mixer to automatically complete the mixing process.

2. Precise control: It can accurately control the various parameters of mixing to ensure that each batch of materials can get a consistent mixing effect, thereby ensuring the stability and reliability of product quality.

3. High uniformity: The horizontal mixing method is adopted. Through the synergistic effect of the mixing shaft and the blades, the material is fully turned, sheared and convectively circulated in the cylinder, and various materials of different properties and different particle sizes can be evenly mixed to achieve a high mixing uniformity.

4. Strong adaptability: It is suitable for a variety of types of materials, including dry powder, granules, liquids and different combinations between them, and can also handle materials of different viscosities and specific gravities.

5. Large processing capacity: Generally, it has a large volume and a high mixing power, and can handle a large amount of materials in a short time to achieve efficient production.

6. Easy to clean: The cylinder and mixing parts usually adopt a smooth surface design, the material is not easy to adhere, and some models of equipment are also equipped with automatic cleaning function or cleaning interface.

Breimetz mechanical horizontal mixer is mainly used in organic fertilizer production lines. It adopts a new double-rotor structure. Under the action of two rotors in opposite directions, the material forms a full-scale continuous circulation in the machine trough, achieving the effect of high mixing uniformity and less residue.

High-quality material body: The body shell is made of high-strength carbon steel or stainless steel. Carbon steel has excellent mechanical strength and toughness, and the cost is relatively moderate. After fine anti-rust treatment, it can operate stably for a long time in a conventional industrial environment and resist collision, wear and corrosion to a certain extent in daily use.

Scientifically designed mixing drum: The horizontal cylindrical mixing drum is the core "stage" for material mixing. Its internal space layout is reasonable and carefully designed according to the material flow characteristics and mixing requirements to ensure that the materials can fully roll, convect and blend during the mixing process, minimize the residual dead corners of the materials in the drum, and ensure that each batch of materials can be mixed evenly and efficiently.

Highly automated operation: The operator only needs to set key parameters such as mixing time, mixing speed, feed amount, and discharging conditions through the operation panel before starting the equipment. The equipment can automatically complete a series of operation processes such as material feeding, mixing, and discharging according to the preset program, which greatly reduces manual labor intensity, reduces human operation errors, and improves production efficiency and product quality stability. It is especially suitable for large-scale, continuous production operations.

Excellent mixing effect: Thanks to the multi-type mixing blade design and precise mixing system operation, it can achieve efficient and deep mixing for dry powder, granules, liquid and their complex material systems.Under normal working conditions, the material mixing uniformity can reach 90% - 98%. In special application fields such as fine chemicals and high-end food processing that require extremely high mixing accuracy, through targeted process optimization and equipment debugging, the uniformity can even exceed 99%, effectively ensuring the high-quality output of products.

Wide applicability: Whether it is the strict mixing requirements of cement, sand, gravel, admixtures, etc. in the construction industry to make concrete and dry mortar, or the fine process requirements of flour, sugar, oil, condiments, etc. in the food processing industry to knead dough, mix fillings, and make sauces, or the complex proportioning operations of synthetic coatings and adhesives such as pigments, resins, solvents, etc. in the chemical industry, and the mixing of feed raw materials and fertilizer production in the agricultural field.