Grease roll for embryo rolling machine

The design and installation structure of the Bremetz roll is reasonable. It can be roughly divided into a roller body, two cover and a through shaft composition. The roll body is centrifugal composite casting, the surface layer of the roll body is 40 ~ 45 mm thick high nickel chromium molybdenum alloy material, the inner layer is high-quality gray cast iron, and the shaft is 45 high-quality steel. The roll body, plug cover and shaft assembly of the roll are all processed by cold loading technology, and a pair of oil plugs for adding cooling medium are provided on one end of the plug cover of the roll.

As the main functional part of the billet rolling machine, the quality of the roll and its correct use will directly affect the output and quality of the oil processing products. Therefore, only the further understanding and use of the Bremetz roll can achieve more ideal results.

Parameters:

Equipment model: (diameter) with a diameter of 400mm ~ 815mm, (length) 800mm ~ 2135mm

Roll material: high nickel chromium molybdenum alloy

Casting method: centrifugal composite casting

Surface hardness: (HS) 72 ~ 75

Alloy layer thickness: 30-35mm

Assembly form: patent through shaft cold installation

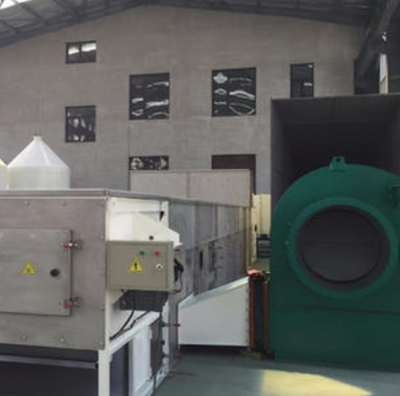

How it works:

The grease roll is a key component of the mill, which is used to press and process metal materials to obtain the desired shape and size. During operation, the grease rolls transfer the metal material to the pressure area between the rolls by rotating motion. Grease rolls are coated with lubricating grease to reduce friction, reduce energy consumption, and improve the surface quality of metal materials. The surface hardness of grease rolls is usually higher and can withstand greater pressure and wear to ensure long-term stable work. Grease rolls are usually assembled in the form of patented cold installation to ensure the stability and accuracy of the roll.