High-efficiency organic fertilizer granule making machine

1. High output: With excellent granulation speed, it can produce a large number of organic fertilizer granules per hour. Its advanced granulation mechanism and power system can ensure that more granulation tasks are completed in unit time.

2. Fast granulation: The optimized granulation process and efficient transmission structure are adopted to greatly shorten the molding time of a single granule.

3. High granule uniformity: Equipped with a precise control system and advanced granulation mold, the size and shape of the granules can be accurately controlled. The size of the organic fertilizer granules produced is uniform and the error range is extremely small.

4. Good granule strength: During the granulation process, the organic fertilizer granules have a high strength through reasonable pressure and special process treatment.

5. Compatible with multiple organic raw materials: It can handle a variety of different types of organic raw materials. Whether it is a single raw material or a mixture of multiple raw materials, it can be effectively made into granules.

6. Low energy consumption: The use of advanced energy-saving technology optimizes the power system and the energy utilization efficiency in the granulation process.

7. High degree of automation: It has functions such as automatic feeding, automatic granulation, and automatic discharging, which can realize one-button operation, greatly improving the convenience and efficiency of the production process.

High-efficiency organic fertilizer granule making machine is a high-performance equipment specially used for the production of organic fertilizer granules. It integrates advanced machinery manufacturing technology and fertilizer production technology, and aims to provide efficient, stable and high-quality granule manufacturing solutions for the organic fertilizer production industry, meeting the strict requirements of modern agriculture on the quality and yield of organic fertilizers.

Its unique internal structure and power transmission system ensure a continuous and stable operating state, effectively reducing the number and time of downtime, greatly improving the overall production efficiency, and making the production process of organic fertilizer particles smoother and more efficient.Whether it is a small organic fertilizer plant or the fertilizer production department of a large agricultural enterprise, it can achieve large-scale production with its efficient granulation capacity.

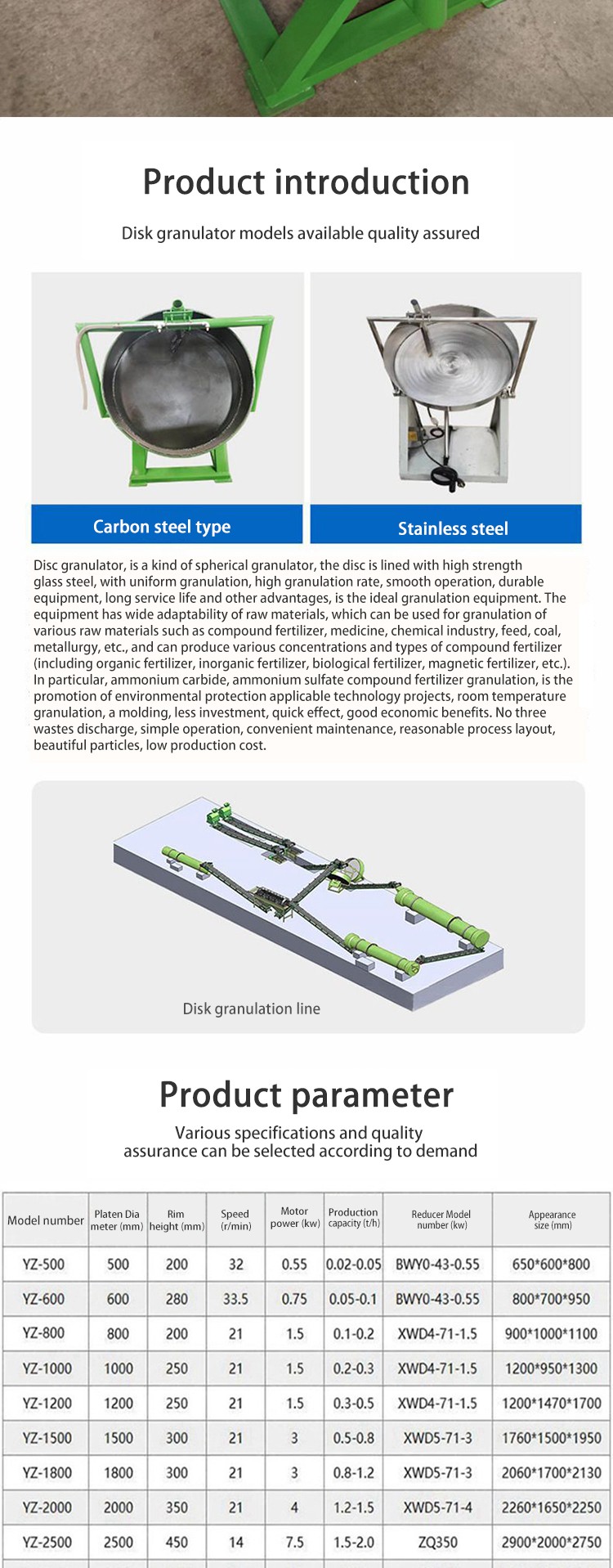

Product parameter,Plate Dia meter (mm),

Rim height (mm),Model number,

Speed (r/min),Motor power (kw),

Production capacity (t/h),Reducer Model number (kw),Appearance size (mm).

YZ-500,500,200,32,0.55,0.02-0.05,BWY0-43-0.55,650*600*800;

YZ-600,600,280,33.5,0.75,0.05-0.1,BWY0-43-0.55,800*700*950;

YZ-800,800,200,21,1.5,0.1-0.2,XWD4-71-1.5,900*1000*1100;

YZ-1000,1000,250,21,1.5,0.2-0.3,XWD4-71-1.5

1200*950*1300;

YZ-1200,1200,250,21,1.5,0.3-0.5,XWD4-71-1.5,1200*1470*1700;

YZ-1500,1500,300,21,3,0.5-0.8,XWD5-71-3,1760*1500*1950;

YZ-1800,1800,300,21,3,0.8-1.2,XWD5-71-3,2060*1700*2130;

YZ-2000,2000,350,21,4,1.2-1.5,XWD5-71-4 ,2260*1650*2250;

YZ-2500,2500,450,14,7.5,1.5-2.0,ZQ350,

2900*2000*2750.

Advanced technology,The whole arc structure reducer and the motor are driven by flexible belt, which can start smoothly and increase the service life.

High granulation rate,The granulation rate can reach more than 93% and three hree discharge ports are provided to facilitate intermittent production, reduce labor intensity and improve production efficiencyase the service life.

Smooth running,The bottom of the disk is strengthened by a number of radiation steel plates, and the base design is thickened and strengthened, which is durable and stable.

Granulation is uniform and easy to operate.

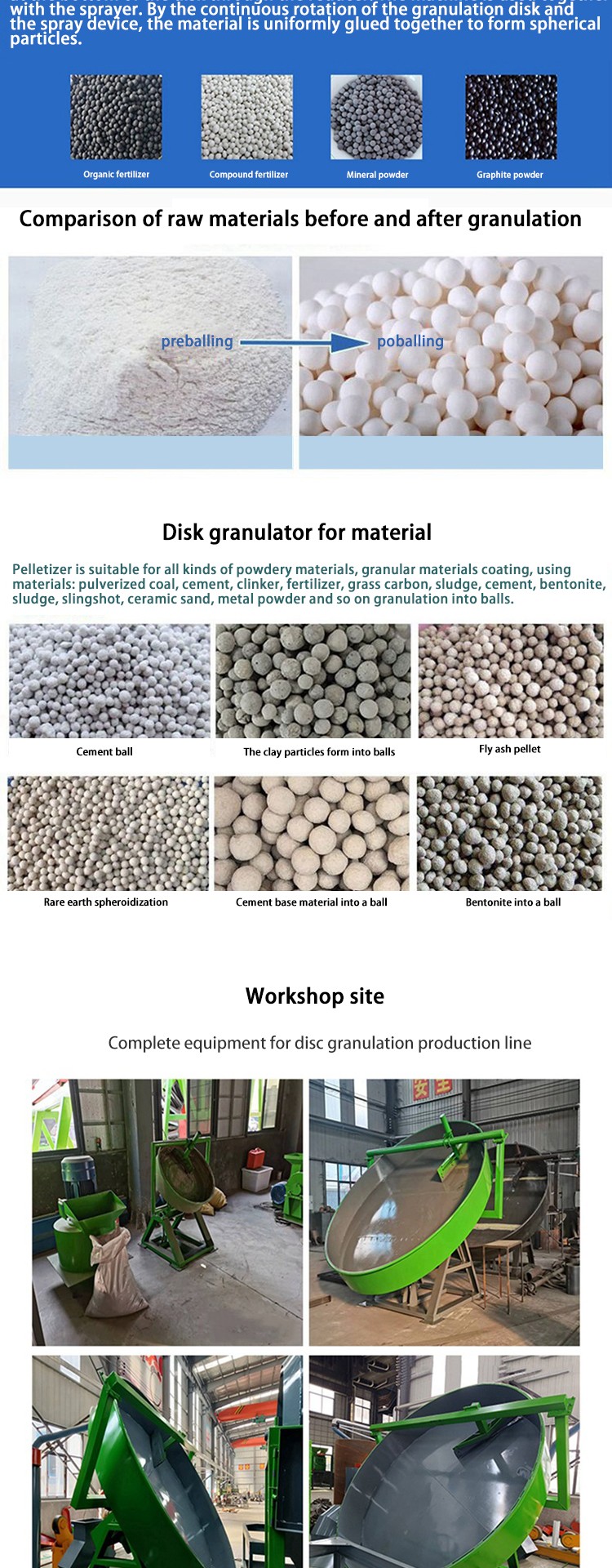

Suitable for all kinds of powdery materials, granular materials coating, using materials: pulverized coal, cement, clinker, fertilizer, grass carbon, sludge, cement, bentonite, sludge, slingshot, ceramic sand, metal powder and so on granulation into balls.

Wide range of application,Widely used in organic and inorganic compound fertilizer, cat litter, fly ash and other granulation,Livestock manure,Sludge refuse,bentonite,Furfural residue of wine lees and medicinal residue,Pulverized coal,coal.

Applicable to multiple fields ,Organic fertilizer plant,Wide adaptability of raw materials, suitable for fertilizer, medicine, chemical, feed and other raw materials granulation, the product granulation rate is high.

We provide reliable quality assurance for High - efficiency organic fertilizer granule making machine, and the warranty period for the main body of the equipment is 1 year. During the warranty period, if there is a failure caused by equipment quality problems, we will provide free repair services and replace damaged parts.