Biomass pelletizing machine

1. Renewable energy conversion: The biomass pelletizer can convert various biomass resources, such as crop straw, wood chips, rice husks, livestock and poultry manure, etc., into high-density biomass pellet fuel. In the production process, compared with the traditional biomass combustion method, the pellet fuel produced by the pelletizer has the characteristics of full combustion and low emissions.

2. Good particle uniformity: The biomass pelletizer can ensure the uniform size and regular shape of the produced particles through advanced mechanical structure and precise control technology. This uniformity is not only conducive to the storage and transportation of pellet fuel, but also can ensure stable combustion effect during the combustion process, avoiding the problem of incomplete combustion caused by differences in particle size.

3. High yield: The biomass pelletizer has efficient production capacity, and its design and working principle can realize continuous and stable pelletizing operations. A large number of biomass pellets can be produced in a unit time to meet the needs of large-scale production and energy supply.

4. Rapid prototyping: With optimized mechanical structure and reasonable process parameters, the biomass pelletizer can enable biomass raw materials to complete the transformation from loose state to formed particles in a short time.

5. Wide material adaptability: It can process a variety of biomass raw materials of different types, different humidity and different particle sizes. This wide adaptability allows the pelletizer to use the abundant local biomass resources for production in different regions and seasons.

6. Customizable production: It can be customized and produced according to the special needs of users. It can also adjust the key components of the pelletizer such as the roller and mold according to the characteristics of different biomass raw materials to achieve the best pelletizing effect and meet the diverse market needs.

Biomass pelletizer is an advanced mechanical equipment specially used to process biomass raw materials into pellet fuel or other biomass products. It plays a vital role in the field of biomass energy utilization and environmental protection. Through a series of physical processing processes, it converts the originally loose and irregular biomass materials into pellet products with uniform specifications, high density and easy to store and transport.

model,Outputkg/h,power (kw),Dimensions (mm),weight

300,200-300,22,1280*560*1220,1,

400,400-600,37,1390*650*1290,1.4

470,1000,75,2100*1020*1985,4.2

560,1500,90,2300*1180*2200,6.1

580,2000,110,2350*1230*2300,6.5

product detail presentation Carefully designed in every detail.

The mold is placed vertically No arching, easy to dissipate heat.

automatic lubrication system automatic grease pump.

Double-sided mold double life High quality material.

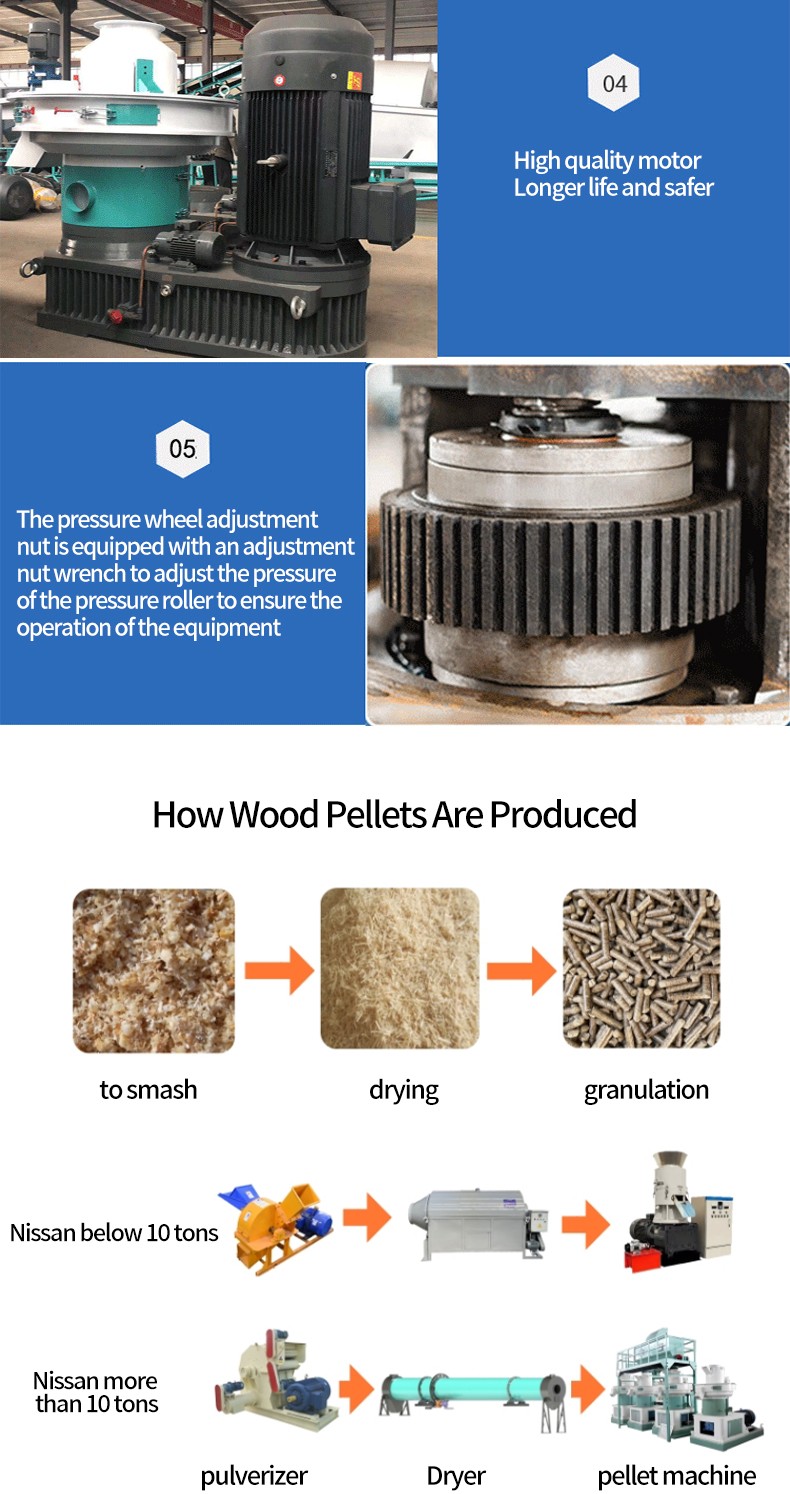

The pressure wheel adjustment nut is equipped with an adjustment nut wrench to adjust the pressure of the pressure roller to ensure the operation of the equipment.

High quality motor Longer life and safer.

It has strong material adaptability and can process various types of biomass raw materials, whether it is wood biomass, herbaceous biomass, other fiber biomass, or even mixed biomass raw materials, it can be granulated smoothly.

The equipment operates stably and reliably, thanks to its durable mechanical structure and precise control system. During long-term operation, it can maintain a stable working state and reduce production interruptions caused by equipment failure. At the same time, the reasonable power configuration and transmission system design enable the granulator to effectively control energy consumption while producing efficiently, thus reducing production costs.

We have a professional installation team to provide door-to-door installation services for customers. During the installation process, the equipment is fully debugged to ensure that all parameters of the equipment meet the requirements before delivery. At the same time, comprehensive training is provided for customers' operators, including equipment operation procedures, daily maintenance points, troubleshooting and handling of common faults, etc., to ensure that operators can master the use and maintenance skills of the equipment.

We have established a complete after-sales service network, with after-sales service centers and spare parts warehouses in many regions across the country. We are equipped with professional maintenance engineers to respond to customers' maintenance requests in a timely manner when their equipment fails. We provide regular equipment maintenance advice and door-to-door maintenance services to extend the service life of the equipment and ensure long-term stable operation of the equipment.