Jaw Crusher

1. Large crushing ratio: It can crush large block materials into smaller particles, and some advanced models have higher crushing ratios. It can effectively crush the original large pieces of ore or rock and other materials into suitable particle sizes.

2. Fast crushing: Its working principle is based on the reciprocating motion of the movable jaw, which continuously squeezes and crushes the material. It reduces the residence time of the material in the crushing chamber, thereby improving the overall crushing efficiency.

3. Simple structure: The mechanical structure of the jaw crusher is relatively simple, mainly composed of components such as the frame, movable jaw, fixed jaw, and eccentric shaft. This simple structural design makes the equipment have a low failure rate and is easy to maintain and repair.

4. Durable components: Key components such as jaw plates and eccentric shafts are made of high-strength and wear-resistant materials. It can withstand the strong impact and friction of the material, reduce the wear and damage of the equipment, and ensure the long-term stable operation of the equipment.

5. Strong adaptability: It can adapt to various materials of different hardness, whether it is granite and iron ore with higher hardness, or limestone and gypsum with slightly lower hardness, it can be effectively crushed.

Uniform crushing: Through reasonable design of movable jaw and fixed jaw, as well as precise motion parameter setting, jaw crusher can achieve uniform crushing of materials.

6. High safety performance: The equipment is designed with full consideration of the safety of operators. Its operation process is relatively smooth, reducing safety hazards caused by equipment vibration or loose parts.

7. Low noise and dust control: With the development of technology, modern jaw crushers have made great improvements in noise reduction and dust control. By optimizing the structure of the equipment and adopting sealing design and other measures, the noise generation can be effectively reduced, the flying of dust can be reduced, and the working environment can be improved.

Jaw crusher is a kind of high-efficiency crushing equipment widely used in mining, construction, metallurgy and other industries. It occupies an important position in the field of material processing with its powerful crushing capacity, stable performance and reliable quality.

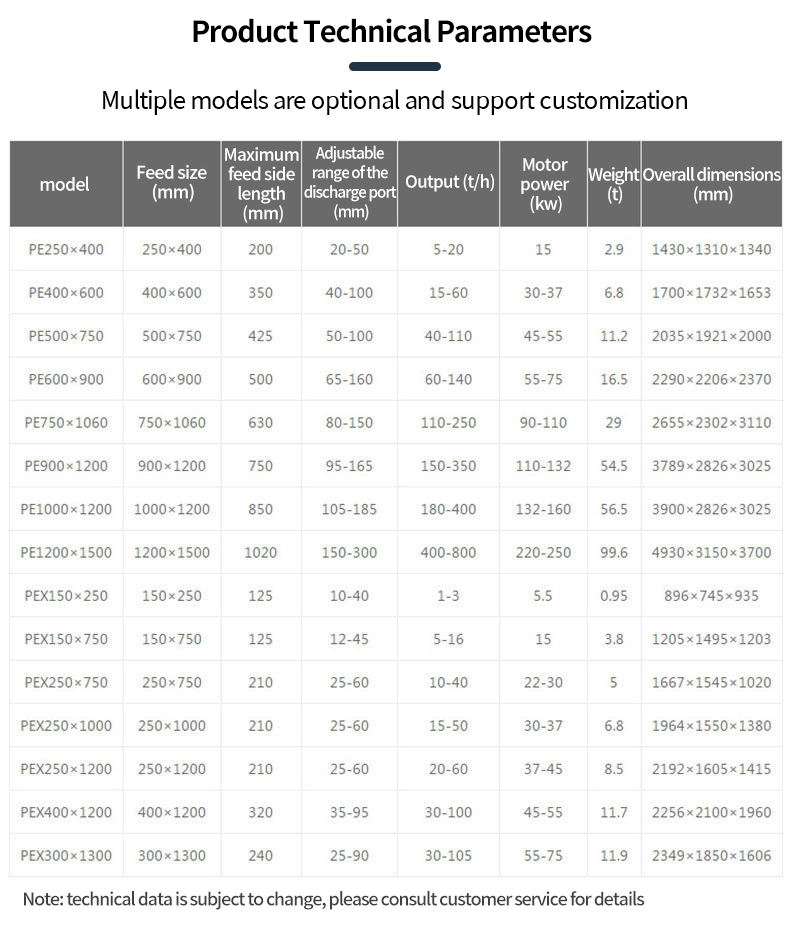

Model, feed size (mm), maximum feed side length (mm), discharge port adjustment range (mm), output (tons/hour), motor power (kW), weight (t), overall dimensions (mm).

PE250×400,250×400,200,20-50,5-20,15,2.9,1430×1310×1340; PE400×600,400×600,350,40-100,15-60,30-37,6.8,1700×1732×1653; PE500×750,5 00×750, 425, 50-100, 40-110, 45-55, 11.2, 2035×1921×2000; PE600×900, 600×900, 500, 65-160, 60-140, 55-75, 16.5, 2290×2206×2370; PE750×1060, 750×1060, 630, 80-150, 110-250, 90-110, 29, 2655×2302×3110; 10-132,54.5,3789×2826×3025; PE1000×1200,1000×1200,850,105-185,180-400,132-160,56.5,3900×2826×3025.

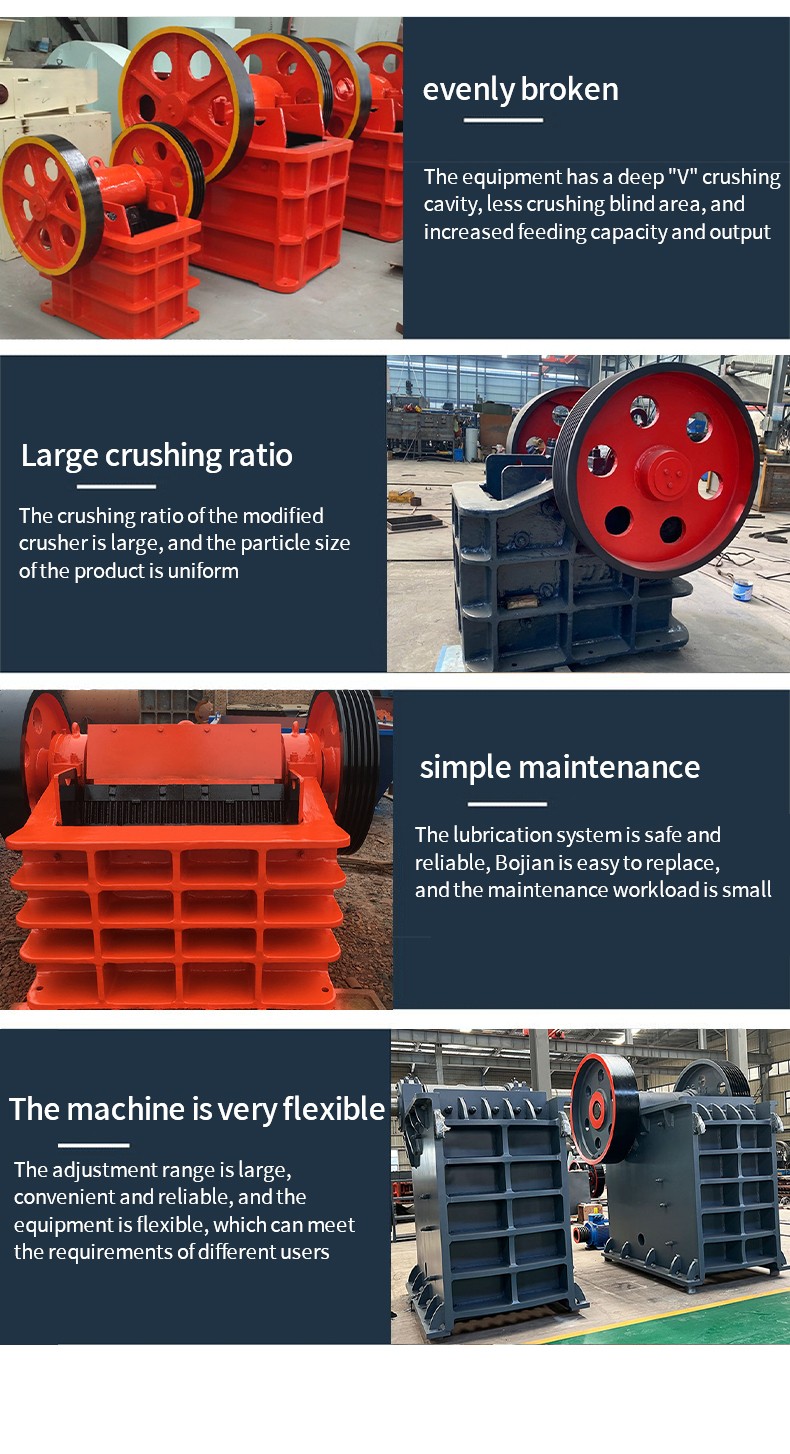

Large crushing ratio, the crusher after modification has a large crushing ratio and uniform product particle size;

Uniform crushing, the crushing chamber of the equipment is deep "V" shaped, with fewer crushing blind spots, increased feeding capacity and output;

Simple maintenance, safe and reliable lubrication system, easy grease replacement, and small maintenance workload;

The machine is very flexible, with a large adjustment range, convenient and reliable, and flexible equipment that can meet the requirements of different users.

Metal ore crushing: In the mining process of metal mines, such as gold, silver, copper, iron, lead and zinc, jaw crushers are widely used for primary crushing.

Non-metallic ore crushing: For non-metallic ores, such as quartz, mica, gypsum, limestone, etc., jaw crushers are also indispensable equipment.

Sand and gravel aggregate production: It is one of the key equipment for producing sand and gravel aggregates. In the processing of construction sand and stone, jaw crushers are used to coarsely crush various rocks, such as granite, basalt, diabase, etc.

Brick raw material processing: In the brick industry, jaw crushers can be used to crush clay, shale and other brick raw materials.

Ore pretreatment: The metallurgical production process usually requires pretreatment of the ore to crush large pieces of metallurgical ores, such as bauxite, manganese ore, chromium ore, etc., into a particle size range suitable for subsequent beneficiation, sintering or direct smelting.

Waste slag recycling: The metallurgical industry produces a large amount of waste slag, such as steel slag, blast furnace slag, etc. Jaw crushers can be used to crush these waste residues.

Raw material crushing: In the processing of chemical raw materials, many solid raw materials need to be crushed.