High efficiency drum granulator

1. High output: It has excellent production efficiency and can produce a large amount of granular products per unit time. The design and operation of its drum are conducive to the rapid agglomeration and granulation of materials. Compared with some traditional granulation equipment, the output is significantly improved.

2. Continuous and stable operation: It can continue to operate stably for a long time, reducing downtime caused by equipment failure or unstable factors.

3. High particle uniformity: particles with uniform particle size and regular shape can be produced. During the rotation of the drum, the materials are uniformly tumbling and agglomerated, and combined with reasonable process parameter control, the differences in particle size and shape are minimal.

4. Excellent particle strength: The particles produced have good strength and compactness. The unique material movement pattern in the drum promotes the full combination of particles. The resulting particles can withstand a certain external force and are not easily broken or pulverized.

5. A variety of material handling capabilities: able to handle a variety of materials with different properties, including powdery, fine granular and materials with a certain viscosity. Whether it is chemical raw materials, fertilizer ingredients, food additives or pharmaceutical powders, etc., they can be effectively granulated in a high-efficiency drum granulator.

6. Adaptability to complex formulas: It can also perform well on materials containing multiple ingredients and complex formulas. High-efficiency drum granulators can handle these situations well, ensuring that the various ingredients are mixed evenly and formed into high-quality granules.

The high-efficiency rotary drum granulator is an advanced equipment that occupies an important position in the field of granule manufacturing and is widely used in fertilizer, chemical, food, pharmaceutical and other industries. Based on the unique rotary drum design and working principle, it can efficiently convert various powdery and fine granular materials into granular products with uniform particle size and excellent quality, providing a reliable granulation solution for modern industrial production.

The high-efficiency rotary drum granulator has an impressive production capacity and can produce a large number of granular products per hour. Its high production performance is due to the reasonable design of the rotary drum and the optimized working parameters, which meets the needs of large-scale industrial production and effectively improves the production efficiency and economic benefits of the enterprise.

Application areas: In the fertilizer industry, the high-efficiency drum granulator is the core equipment for manufacturing granular fertilizers such as compound fertilizers and organic fertilizers. It can mix and granulate various raw materials such as nitrogen fertilizers, phosphate fertilizers, and potash fertilizers with binders to produce fertilizer products with uniform nutrients and full particles.

In the chemical industry, it is used to produce granular forms of various chemical products. Chemical raw materials can be made into particles with specific particle sizes and shapes to improve the performance and use effects of products.

In the food industry, in food processing, it can be used to make some granular foods. Mixing food raw materials with appropriate binders in a drum granulator can produce food particles with beautiful shapes, good taste, and easy packaging and consumption.

In the pharmaceutical industry, it is one of the important equipment for drug granulation in the pharmaceutical process. It can mix drug powder with excipients to make granular drug intermediates or finished products.

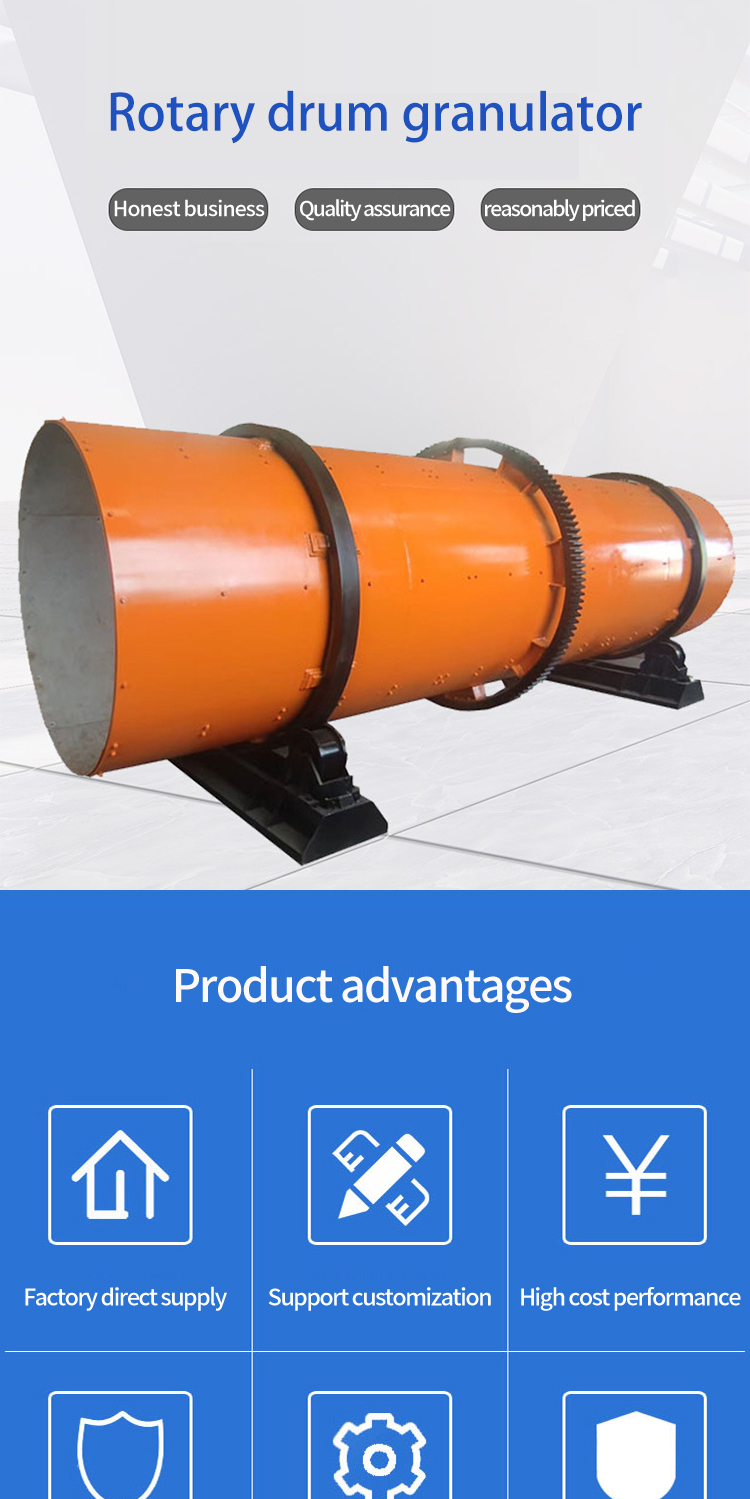

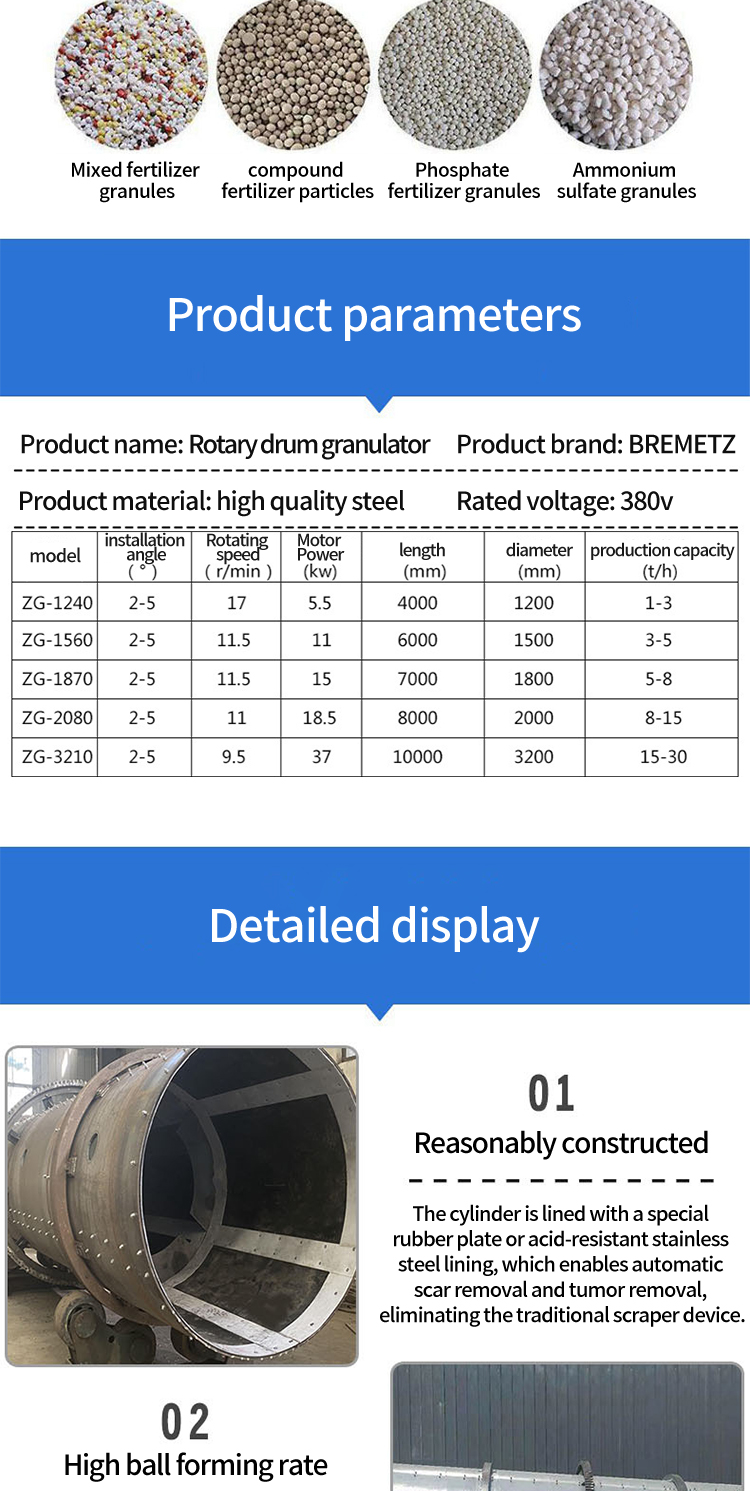

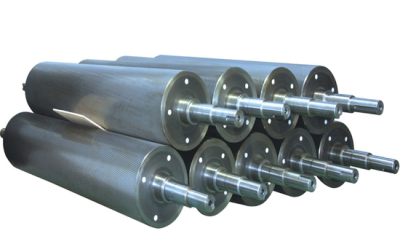

Product name: Rotary drum granulator

Product brand: BREMETZ

Product material: high quality steel

Rated voltage: 380v

model:ZG-1240,ZG-1560,ZG-1870,ZG-2080,ZG-3210

installation angle (°):2-5,2-5,2-5,2-5,2-5,

Rotating speed (r/min):17,11.5,11.5,11,9.5

Motor Power (kw):5.5,11,15,18.5,37

length (mm):4000,6000,7000,8000,10000

diameter (mm):1200,1500,1800,2000,3200

production capacity (t/h):1-3,3-5,5-8,8-15,15-30

Reasonably constructed,The cylinder is lined with a special rubber plate or acid-resistant stainless steel lining, which enables automatic scar removal and tumor removal, eliminating the traditional scraper device.

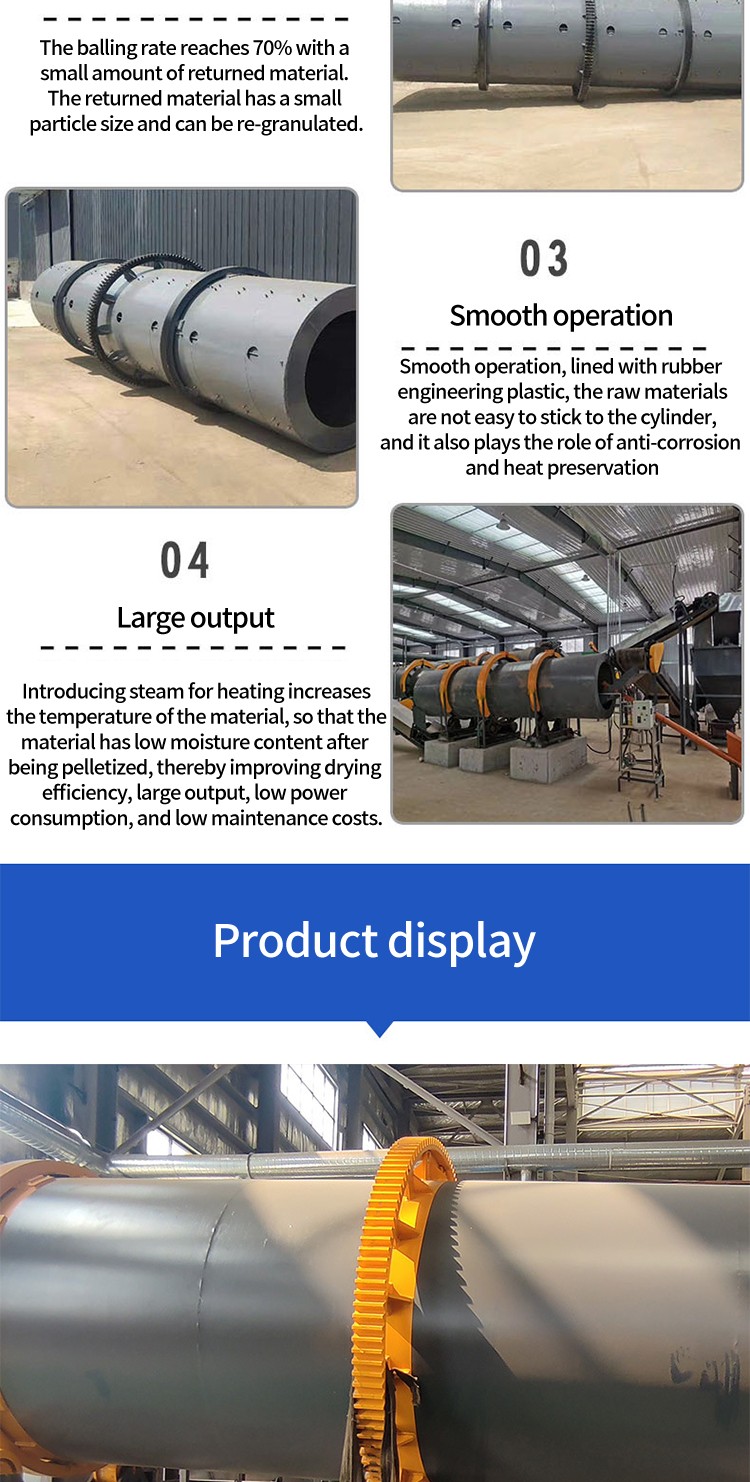

High ball forming rate,The balling rate reaches 70% with a small amount of returned material. The returned material has a small particle size and can be re-granulated.

Smooth operation, lined with rubber engineering plastic, the raw materials are not easy to stick to the cylinder, and it also plays the role of anti-corrosion and heat preservation.

Introducing steam for heating increases the temperature of the material, so that the material has low moisture content after being pelletized, thereby improving drying efficiency, large output, low power consumption, and low maintenance costs.

The company provides a professional installation team to install the high-efficiency drum granulator to the location specified by the user and conduct comprehensive commissioning. During the installation process, ensure that all parts of the equipment are installed correctly and firmly, the electrical connection is safe and reliable, and the mechanical transmission parts operate smoothly.