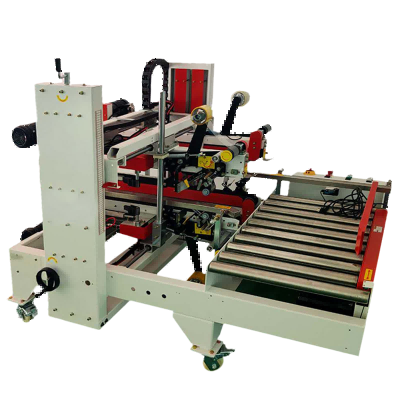

Double roll extrusion granulator

1. Exquisite and reasonable structural design: The overall layout is compact and occupies a small area, which is convenient for placing and arranging production lines in various production sites.

2. Excellent granulation: Through the rotation and extrusion of the two rollers, the size and shape of the granules can be accurately controlled. The granules are uniform and regular in shape, spherical or elliptical, with a smooth surface and high compactness.

3. Wide range of material adaptation: Whether it is powder, fine particles, or materials with a certain viscosity, it can be processed, and it has strong compatibility with physical properties such as moisture content and particle size of the materials.

4. Easy operation and maintenance: The operation interface is humanized, and the parameter setting, equipment start and stop and other operations are intuitive and simple. Workers can become proficient after short-term training.

5. Outstanding environmental protection characteristics: The equipment has good sealing, effectively suppresses dust flying, and greatly improves the workshop working environment.

6. Flexible production adjustment: According to market demand, the granulation output can be flexibly controlled by adjusting parameters such as the double roller speed and material feed amount.

Bremetz Machinery's new double-roll extrusion granulator is a new generation of organic fertilizer extrusion granulation equipment developed by our company. This organic fertilizer double-roll granulator has low investment, quick results and good economic benefits. The complete set of equipment has a compact layout, scientific and reasonable, advanced technology, novel and practical, and low energy consumption.

The new double-roll extrusion granulator is mainly used to produce high, medium and low concentration compound fertilizers (including ammonium chloride, ammonium sulfate, organic fertilizer, biological fertilizer) for various crops, especially the granulation of rare earth, potash fertilizer, ammonium carbonate and other series of compound fertilizers.

The new double-roll extrusion granulator of Bremetz Machinery is driven by a motor belt and a pulley, which is transmitted to the driving shaft through a reducer and works synchronously with the driven shaft through split gears. After die extrusion molding, demoulding granulation, crushing and separation, uniform granulation is achieved. The extrusion die is carefully forged with excellent corrosion-resistant and wear-resistant materials. The shape and size of the ball socket on the roller skin can be selected according to user needs. The double-roll extrusion granulator has a wide range of choices. The ball pressing shapes include pillow, semi-circular particle, rod, tablet pill, walnut, flat ball and square strip. The double-roll extrusion granulator is produced by a non-drying normal temperature process and is formed in one time.

A stirring device is installed at the feed port to effectively ensure uniform feeding.

The main frame of the box is equipped with an oiling and self-cleaning device to prevent textile materials from sticking to the roller skin.

The roller skin gap adjustment adopts step-by-step gear adjustment to ensure uniform gap and easy operation.

The roller skin alignment adopts gear internal spline adjustment to ensure neat alignment without misalignment.

The balling rate is as high as 95% or more, and the particle size is good.

The finished particles do not need secondary drying, are produced at room temperature, and have low moisture content.

One-time extrusion molding, high production efficiency.

The product particles are available in a variety of shapes and sizes.