Fertilizer valve packing machine

1. The use of advanced sensor technology can accurately measure and control the packaging weight of fertilizers, ensuring that the weight of each bag of fertilizers meets the set value, and the measurement accuracy is high.

2. It has a fast packaging speed, generally hundreds or even thousands of bags of fertilizers can be packaged per hour, which can meet the needs of large-scale production.

3. It integrates weight display, packaging, timing control, process chain, fault alarm and other functions, and adopts PLC intelligent control instruments to realize automatic feeding, metering, filling, sealing and other operations.

4. It can be applied to various forms of fertilizers such as granules and powders, and can also make corresponding adjustments and optimizations according to different fertilizer characteristics to ensure packaging quality.

5. The design focuses on energy saving, adopts energy-saving motors, electrical components and frequency conversion technology, etc., which reduces the energy consumption of equipment and saves energy costs.

The fertilizer valve bag packaging machine is a highly efficient automated equipment designed specifically for fertilizer packaging needs. It can accurately fill various granular and powdered fertilizers into valve bags according to the predetermined weight and seal them.

High-precision measurement: The use of high-precision weighing sensors and advanced measurement algorithms can accurately control the packaging weight of fertilizers with minimal error. The general static measurement accuracy can reach ±0.1%, and the dynamic measurement accuracy can reach ±0.2%, effectively ensuring that the weight of each bag of fertilizer meets the standard requirements.

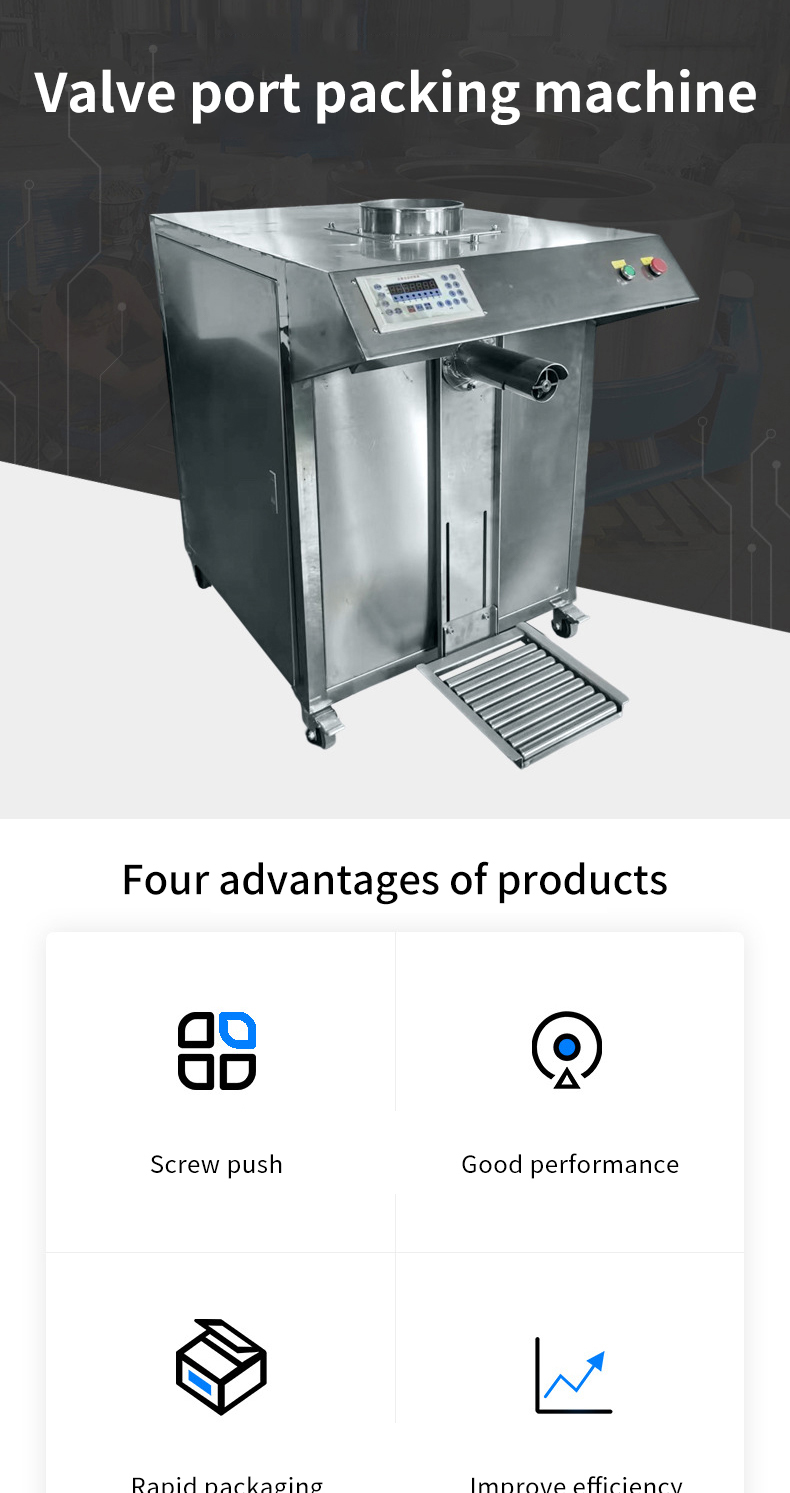

Name: Valve pocket packing machine

Production: The packaging speed is about 1-2 packets per minute, with an error of +-20 grams

Machine size: Length 700MM wide 800MM high 1050MM

Material used: 201 Stainless Steel manufacturing

Motor power: 21.5KW/380V/50HZ

It realizes the fully automated operation from feeding, metering, filling to sealing, reduces manual intervention and reduces labor intensity. The operator only needs to set the relevant parameters on the human-machine interface, and the equipment can run automatically, and can automatically detect and handle various abnormal situations.

It can be used to package a variety of granular and powdered fertilizers, and can handle fertilizer products with different fluidity and particle sizes. In addition, it can be adapted to valve bag packaging of different specifications by simply adjusting and replacing some parts.

The equipment has a reasonable structure design, and the main components are made of high-quality materials, such as stainless steel silos, wear-resistant feeding devices, etc., which have good corrosion resistance and wear resistance and long service life. At the same time, advanced manufacturing technology and strict quality control system ensure the stable performance of the equipment.

It has data storage and statistics functions, can preset cumulative weight or package value, and has power-off protection. It can automatically record data such as shift production, daily production, and cumulative production.