Ultrasonic valve packing machine

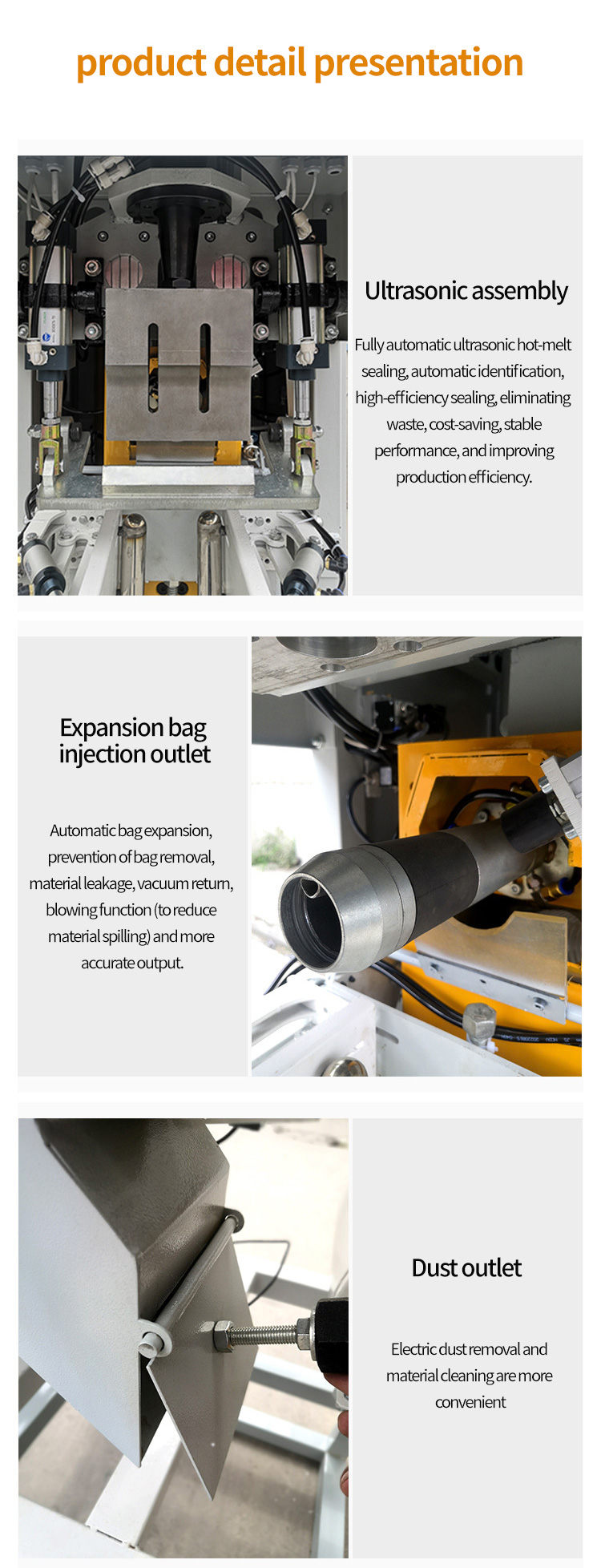

1.Using ultrasonic vibration, the molecules of the packaging material are subjected to friction and heated up instantly, and then they are fused together, forming a seal with high strength and good sealing.

2. Ultrasonic sealing technology has a precise effect on the material, which can avoid common problems such as deformation, wrinkling, and cracking of the seal in heat sealing.

3. It can achieve continuous and stable sealing operations without frequent pauses and adjustments, making the entire packaging process smoother and more efficient.

4. Ultrasonic technology requires almost no additional heating device when sealing, and can complete the sealing only by relying on the heat generated by ultrasonic vibration, which greatly reduces energy consumption.

5. No auxiliary materials such as glue and tape are required, which avoids waste and environmental pollution that may be generated during the production process, making the packaging process cleaner and more environmentally friendly.

Ultrasonic valve packaging machine is a high-efficiency packaging equipment that integrates advanced ultrasonic technology and precise valve control. It is designed for automatic packaging of various products and has a wide range of application prospects in many industries such as food, daily chemicals, and chemicals.

The high-frequency vibration of ultrasound is used to generate intense friction between the molecules of the packaging material. No additional heating elements are required, which avoids the sealing quality problems caused by uneven heating in traditional heat sealing methods, such as wrinkles, bubbles, cracks, etc.

Ultrasonic welding technology is widely adaptable to packaging materials and can be used to seal a variety of materials such as plastic films, aluminum foils, composite materials, etc. In addition, by adjusting the parameters, the best welding effect can be achieved for packaging materials with different thicknesses and material combinations.

Product model: BLMC-50

Product size: 1700-800-2000mm

Sealing mode: Ultrasonic hot melt sealing

Weighing range: 10-50KG

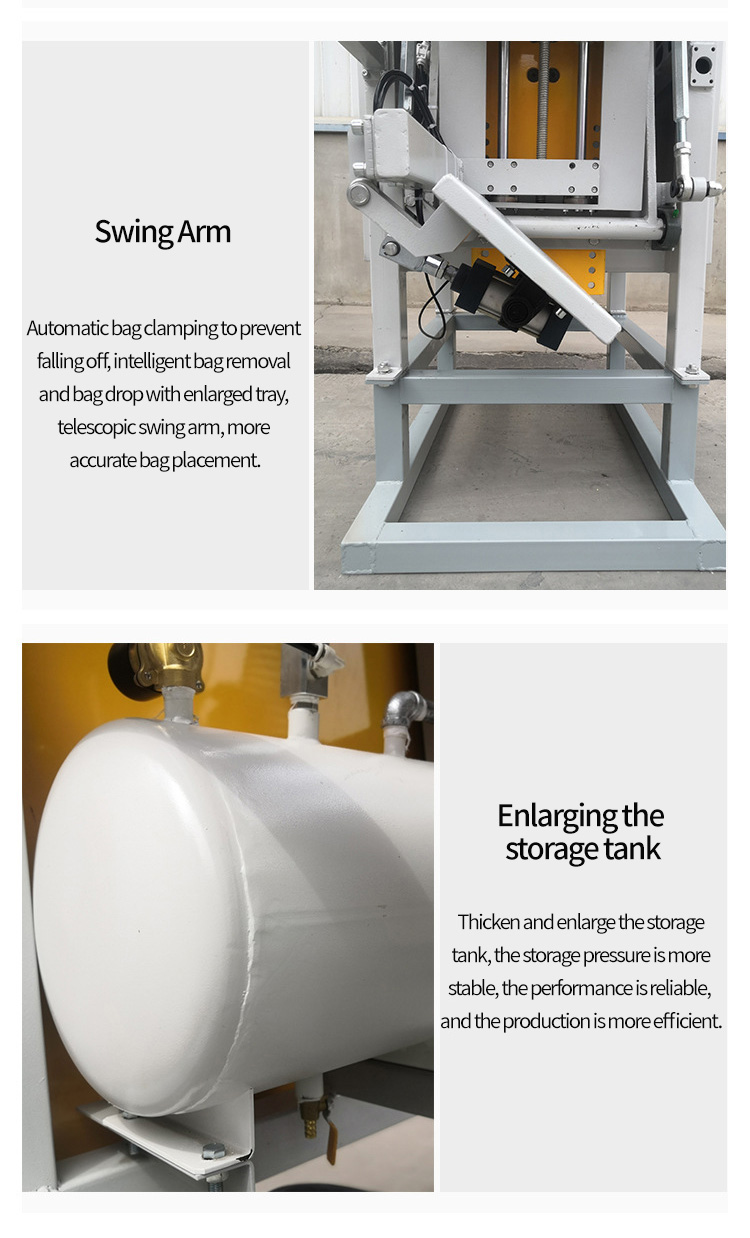

Bag release mode: automatic bag clipping, bag removal

Power mode: pneumatic, electric

Features: high efficiency, energy saving, environmental protection

The use of advanced sensor and microprocessor technology enables precise control of valve opening. Through weight sensors, volume sensors or photoelectric sensors, the filling status of materials is monitored in real time. According to the preset packaging parameters, the microprocessor accurately calculates and controls the opening and closing degree and time of the valve.

The seal formed by ultrasonic sealing is flat, smooth, wrinkle-free, and has high sealing strength and permeability resistance. It can effectively prevent the packaging contents from leaking, getting damp, oxidized or contaminated by microorganisms, and extend the shelf life and shelf life of the product.