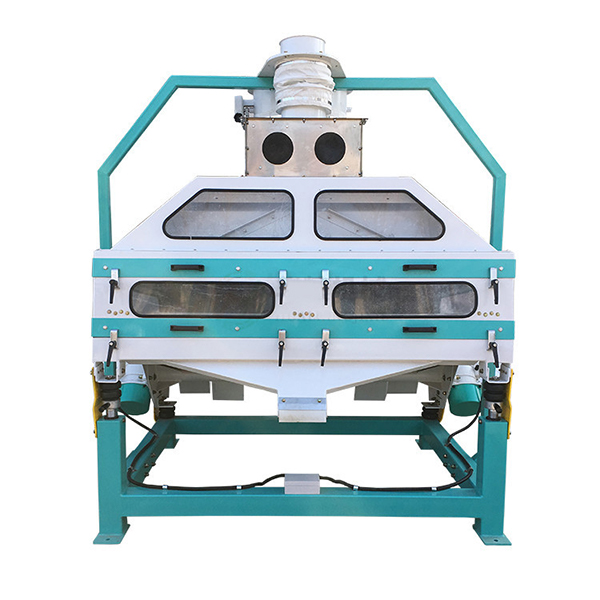

Screening and stone removal machine

1. The product advantages of the screening stone remover are strong screening capabilities, which can quickly and effectively remove stones and impurities from the raw materials and improve the quality of organic fertilizer production.

2. The equipment adopts an automated control system, which is easy to operate, does not require a lot of manpower, and saves production costs. The equipment has a large processing capacity and can meet the needs of organic fertilizer production lines of different sizes, with high production efficiency.

3. The use of advanced technology and energy-saving design can effectively save energy consumption and reduce production costs. By removing stones and impurities, the influence of impurities in the raw materials on the quality of organic fertilizer is avoided, and the quality and purity of the final product are guaranteed.

4. The equipment has a reasonable structure, stable and reliable operation, and convenient operation and maintenance, which reduces production line failures and downtime and ensures production continuity.

The screening stone remover is one of the key equipment in the organic fertilizer production line. It is mainly used to remove impurities and stones from organic raw materials. Its main working principle is to screen the raw materials through a screen barrel with a rotating screen on the axis, and screen out larger stones and impurities to achieve the purpose of stone removal.

Screen: Screens with different apertures are used, mostly made of high-strength stainless steel or wear-resistant alloy, and are selected and replaced according to the particle size requirements of the screened material. The screen is easy to install and maintain and clean.

Vibration mechanism: It is composed of a vibration motor or an eccentric shaft, etc., which produces a stable and adjustable vibration frequency and amplitude. This vibration makes the material jump and roll quickly on the screen, so that small particles can pass through the screen holes smoothly, while large particles remain on the screen, thus completing the screening process.

A special mechanical structure is used, such as a rotating stone removal drum with spiral blades or baffles inside. After the material enters the drum, during the rotation process, the stone is lifted to a certain height and then falls due to the friction with the drum wall and its own gravity, while the material is pushed to the discharge port as the drum rotates.

Equipped with an adjustable feed port and uniform material distribution mechanism, it can control the material feed rate according to production needs and evenly distribute the material on the screen to ensure the stability and consistency of the screening and stone removal process.

There are multiple discharge ports, corresponding to different specifications of screened materials and removed stones. The design of the discharge port is convenient for connecting to subsequent conveying equipment or storage containers, so that the processed materials can smoothly enter the next process or be collected and stored.

Scope of application:

Agricultural field: widely used in the grain processing industry, such as screening and stone removal of rice, wheat, corn and other grains.

Mining industry: can separate ores of different particle sizes, screen out ore particles that meet the requirements of mineral processing, and remove waste rocks and impurities.

Building materials industry: can classify natural sand or crushed stone according to different particle size specifications, remove soil, debris and oversized stones.

Chemical and pharmaceutical industries: in the production process of chemical raw materials and medicines, powdered and granular materials are screened to remove foreign matter and unqualified particles.