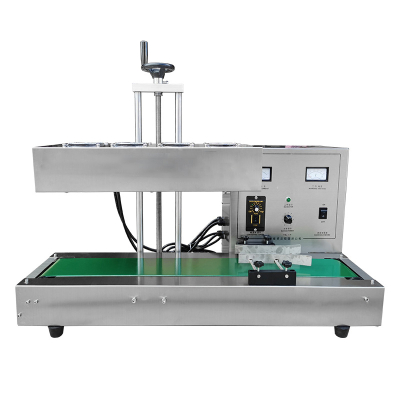

Horizontal urea crusher

1. Simple and compact structure: The overall structure is relatively simple, mainly composed of key components such as drive device, crushing chamber, rotor, screen, etc., without overly complicated transmission and control mechanisms.

2. Small footprint: This crusher adopts a horizontal design, which occupies a small area in the horizontal direction and can be placed more flexibly in the factory layout.

3. Efficient crushing capacity: According to the impact crushing principle, the inner and outer groups of cage bars of the horizontal urea crusher rotate in opposite directions at high speed, so that the material is crushed from the inside to the outside through the impact of the cage bars, and can quickly and effectively crush the urea particles into the required fineness.

4. Wide range of applicable materials: This crusher is not only suitable for the crushing of urea, but also for various single fertilizers with a water content of less than 40%, especially for materials with higher hardness.

5. Large crushing ratio: It can crush larger urea particles into smaller particles at one time, reducing the links of multiple crushing and improving production efficiency.

6. Smooth operation: The rotor of the equipment has been precisely dynamically balanced and debugged, and can maintain a stable operating state during high-speed rotation, reducing the noise caused by vibration and wear on the equipment.

Urea crusher can crush various single fertilizers with water content below 40%, especially suitable for materials with high hardness. The machine is designed based on the impact crushing principle. The inner and outer groups of cage bars rotate at high speed towards each other, and the materials are crushed from the inside to the outside through the impact of the cage bars.

Urea pulverizer mainly uses the grinding and shearing between the high-speed rotating roller and the gravure. The size of the gap determines the degree of material pulverization. The roller speed and roller diameter can be adjusted. After entering the machine body, urea hits the body wall and baffle to be broken, and then is ground into powder by the rack between the roller and the gravure. The gravure gap is adjusted by the adjustment mechanism within the range of 3-12 mm to adjust the degree of pulverization, and the feed inlet adjustment mechanism can control the production volume.

Easy to operate: simple structure, no wearing parts, no dust, no auxiliary dust removal equipment.

High crushing efficiency: The two rollers of the Bremetz mechanical urea crusher rotate in opposite directions, squeezing and crushing the material, with fast crushing speed and no sticking to the roller.

Not easy to block: The feed port of the urea crusher is equipped with a block-breaking tooth roller, which will not be blocked even if there is a small amount of agglomeration and will work continuously.

Wide range of applications: Although it is mainly used for crushing urea, the equipment can also process a variety of other fertilizer raw materials, such as ammonium chloride, ammonium sulfate, monoammonium phosphate, diammonium phosphate, etc. It can also be used for materials with a certain moisture content. It provides a versatile crushing solution for fertilizer manufacturers, reducing the cost and site pressure of equipping a variety of crushing equipment for different raw materials.