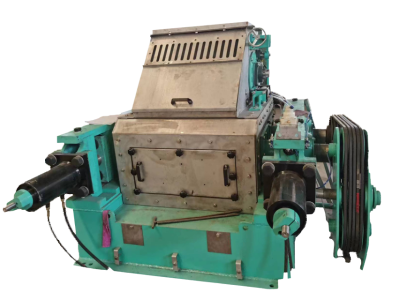

High speed cage crusher

1. It can achieve a larger crushing ratio. It can crush larger raw materials into fine particles.

2. The material is fully stirred and ground in the crushing cage, and the crushing force in all directions is relatively balanced, so that the final crushed particle size is relatively consistent.

3. High speed cage crusher has strong adaptability to materials, whether it is hard or relatively soft materials, it can be effectively crushed.

4. It also has a certain tolerance for the humidity of the material. Even materials containing a certain amount of moisture can be crushed normally.

5. The structural design of high speed cage crusher is relatively simple, the equipment reliability is high, and there are relatively few failure points.

The high-speed rotating crushing cage can crush materials quickly, greatly improving production efficiency. It can process a large amount of materials in a short time and is suitable for large-scale production operations.

Larger raw materials can be crushed into fine particles to meet the fine requirements of various industries for material particle size, such as crushing block materials with a diameter of 50-100 mm into particles less than 10 mm or even smaller.

During the crushing process, the material is fully stirred and ground in the crushing cage, and the crushing force in all directions is relatively balanced, so that the size of the crushed particles finally produced is relatively consistent, which helps to improve the quality and performance of subsequent products.

The working principle is mainly impact and grinding, rather than simple extrusion, so the crushed materials can maintain a better shape. For example, cubic sand particles can provide better bonding properties in the preparation of building materials such as concrete.

The structure is relatively simple, mainly composed of crushing cage, motor, transmission device and shell, with relatively few failure points. Its key components are usually made of high-strength wear-resistant materials, which greatly prolongs the service life of the equipment.

The use of effective sealing measures and dust collection system, the sealed shell can prevent dust from spilling out, at the same time, the dust removal equipment can collect and process the dust generated during the crushing process, greatly reducing the pollution of dust to the environment.