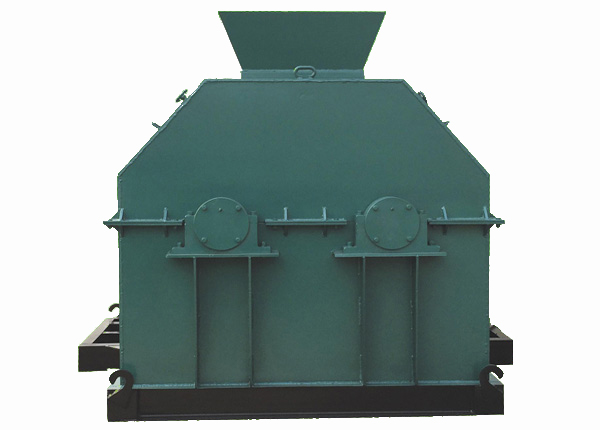

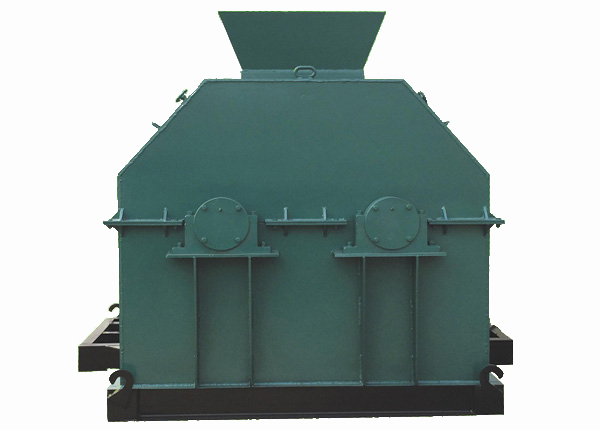

Double shaft chain grinder

1. Uniform crushing of materials: The high-strength wear-resistant carbide chain plate with a double-shaft structure and synchronous rotation speed can make the materials receive uniform impact force during the crushing process, thereby achieving uniform crushing of the materials.

2. Fully disperse the materials: It can not only crush large-volume materials into smaller particles, but also fully disperse the materials to avoid material agglomeration.

3. Can handle a variety of materials: It is suitable for crushing various block and granular materials in the fertilizer production industry such as organic fertilizer, inorganic fertilizer, and compound fertilizer, and can also be used for crushing medium-hardness materials.

4. Can handle wet materials: It can crush wet materials such as phosphate fertilizer and calcium and various scale compound fertilizer products that have not been dried and contain 14% water and 6% free acid.

5. Large-volume continuous operation: It has a large production capacity and can meet the needs of large-scale production.

6. Quickly crush materials: The high-speed rotating chain can quickly impact and crush the materials, and its crushing speed is faster than some traditional crushers.

Double shaft chain grinder is an impact crusher. When working, the motor drives the double rotors to rotate at high speed. The high-speed rotating chain impacts the material blocks entering the crushing chamber, breaking the materials into smaller particles. During the crushing process, due to the synchronous speed of the double rotors and the special structural design, the materials can be subjected to uniform impact force, thereby achieving uniform crushing of the materials, and can fully disperse the materials to avoid material agglomeration.

The double-shaft structure is adopted, and each rotor shaft has its own transmission motor, which ensures the stability and efficiency of the equipment operation. The body of the machine is lined with rubber sheets to prevent sticking and friction of the body steel plate.

Equipped with high-strength wear-resistant carbide chain plates with synchronous speed, the material can be subjected to uniform impact force during the crushing process, thereby achieving uniform crushing of the material and making the particle size of the crushed material more consistent. In addition, the equipment can also fully break up the material, avoid material agglomeration, and improve the fluidity and mixing effect of the material.

Stable equipment performance: The frame is welded with thickened channel steel and steel plate, with a solid structure that can withstand large crushing and impact forces, ensuring the stability of the equipment during long-term operation. At the same time, the double-axis design makes the equipment's force more uniform, reduces vibration and noise, and extends the equipment's service life.

Wide range of applications: It is suitable for crushing various block and granular materials in the fertilizer production industries such as organic fertilizer, inorganic fertilizer, compound fertilizer, etc. It can also be used for crushing medium-hard materials in the chemical, mining, waste treatment and other industries. It can also crush undried 14% water-containing, 6% free acid-containing phosphate fertilizer calcium and various scale-shell compound fertilizer products and other wet materials, overcoming the problems of clogging and bonding that some traditional crushers are prone to when processing wet materials.

Provide customers with equipment operation and maintenance training, so that customers' operators can be familiar with the working principle, operating procedures and precautions of the equipment, master basic maintenance skills, and correctly operate and maintain the equipment.