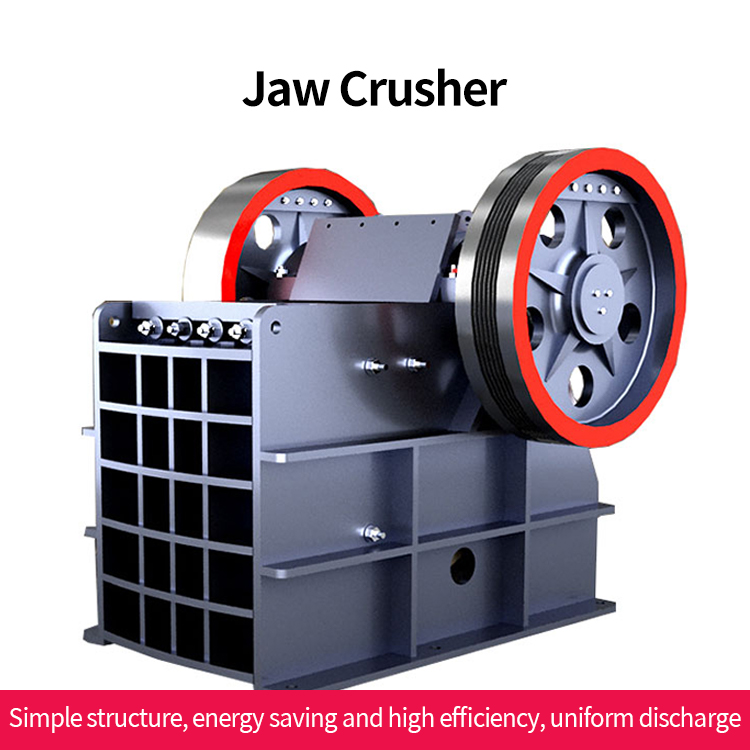

Automatic jaw crusher

1. Its jaw plate structure is reasonably designed, and through the mutual squeezing of the movable jaw and the fixed jaw, it can effectively crush materials of various hardness.

2. During the crushing process, the automatic jaw crusher can ensure the uniformity of the product particle size.

3. The equipment adopts an advanced automatic control system, which can automatically adjust the crushing parameters according to the nature of the material and the feed amount.

4. The equipment is usually equipped with various sensors and monitoring devices, which can monitor the operating status of the equipment in real time.

5. Some advanced automatic jaw crushers support remote operation and data management functions.

It is made of high-strength cast steel or high-quality steel plates welded together, has good rigidity and stability, can withstand huge crushing force, and ensures stable operation of the equipment under harsh working conditions.

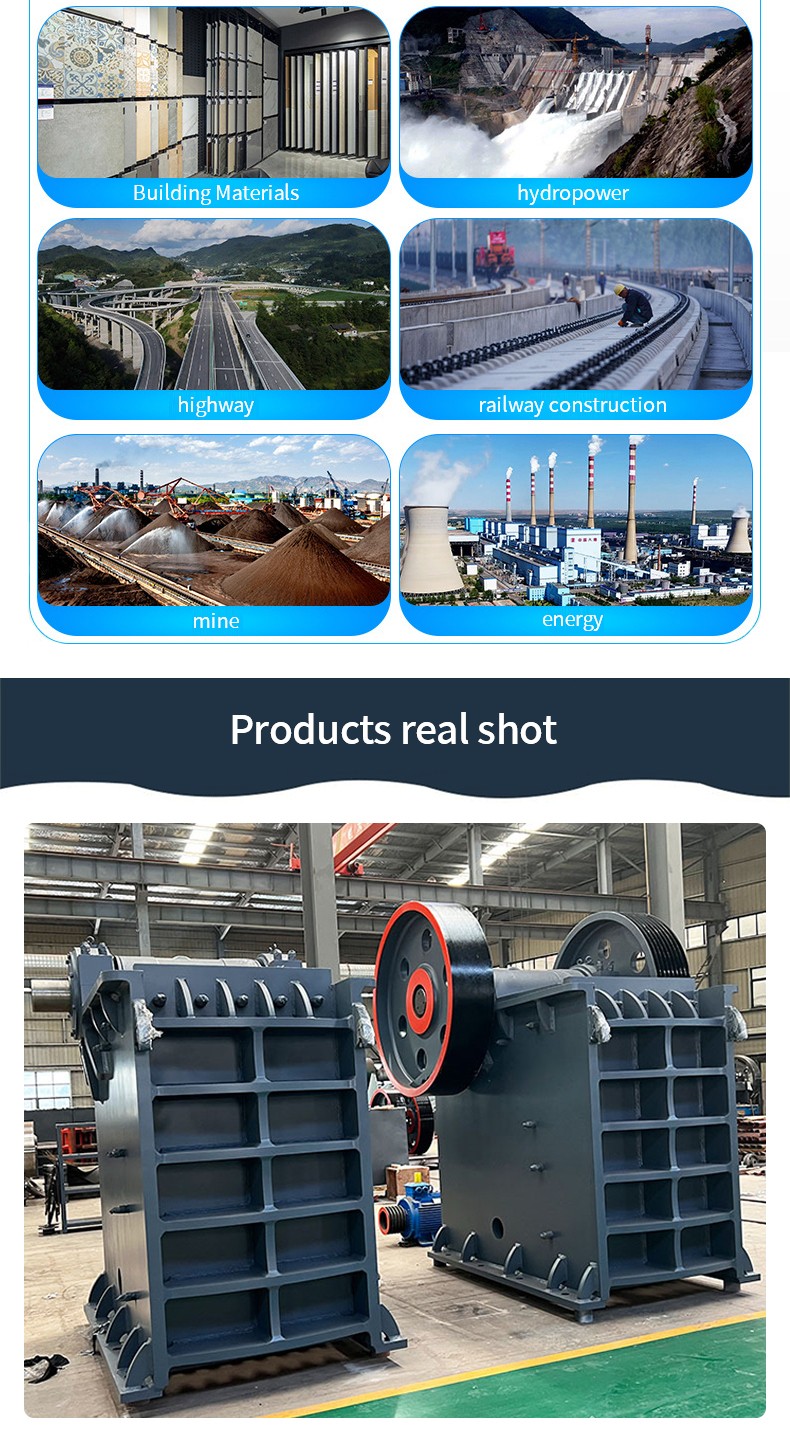

It has a large crushing ratio and can quickly crush large-sized materials. It is suitable for materials of various hardness and has a processing capacity of several tons to hundreds of tons per hour.

It runs smoothly, with low noise and vibration, reducing the impact on the surrounding environment and ensuring production continuity.

Simple operation, high degree of automation, and reduced manual intervention; reasonable structural design, easy maintenance, and reduced maintenance costs.

Equipped with advanced sensors and controllers, it can realize functions such as automatic feeding, automatic adjustment of discharge port, and real-time monitoring of equipment operating status to ensure efficient and stable operation of the equipment.