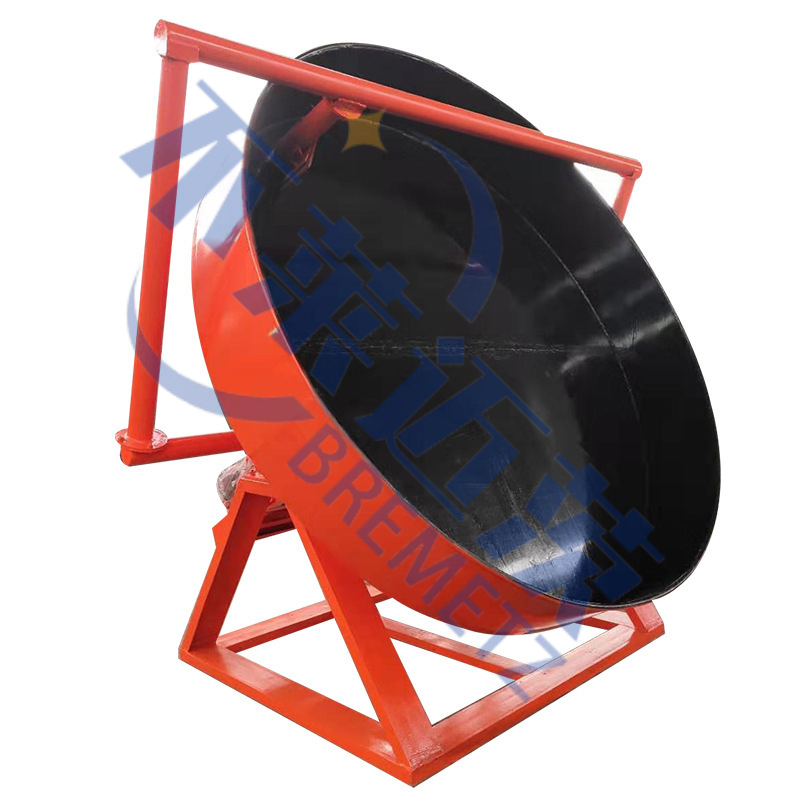

Disc granulator, precise control of the production process

The disc granulator developed by our company is equipped with an advanced intelligent control system, making the operation easier and more efficient. Through the intuitive human-machine interface, operators can easily set and adjust various parameters in the granulation process, such as disc speed, tilt angle, spray volume, material feed speed, etc. At the same time, the intelligent control system also has a real-time monitoring function, which can collect and analyze key data such as the operating status of the equipment, humidity and temperature of the material in real time. Once an abnormal situation occurs, the system will immediately issue an alarm and provide corresponding solutions to ensure the safety and stability of the production process. This intelligent control method not only reduces the labor intensity of operators, but also greatly improves production efficiency and product quality.

The disc's tilt angle and rotation speed can be precisely adjusted according to the characteristics of different materials and granulation requirements. The adjustable range of the tilt angle is 360°. This refined design allows the material to form an optimal rolling trajectory in the disc, promoting uniform growth and forming of particles.