Organic fertilizer pellet machine

1. High particle uniformity: The organic fertilizer pellet machine can accurately control the size and shape of the particles, and the produced particles are uniform in size.

2. Good particle strength: The produced organic fertilizer particles have high strength. During the particle formation process, the particles are compacted through reasonable pressure and process. In this way, the particles are not easy to break during subsequent transportation, storage and application.

3. Fast granulation: It has an efficient granulation mechanism and can complete the production of a large number of organic fertilizer particles in a short time.

4. Continuous and stable operation: The equipment is reasonably designed, has good stability, and can operate continuously for a long time.

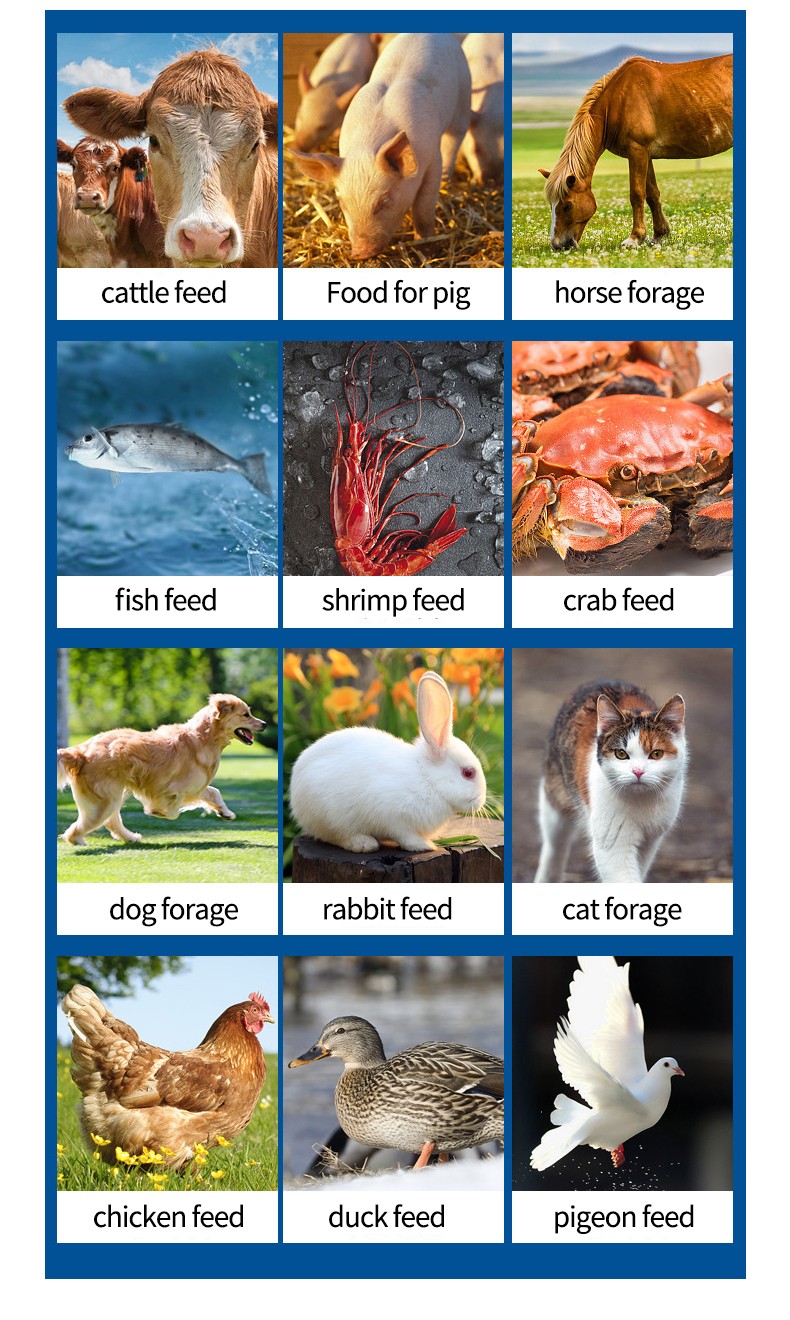

5. Compatible with multiple organic raw materials: It can handle a variety of different types of organic raw materials, such as livestock and poultry manure, crop straw, biogas residue, etc. Whether it is a single raw material or a mixture of multiple raw materials, the organic fertilizer pellet machine can effectively make it into particles.

6. Low energy consumption: During the granulation process, the organic fertilizer pellet machine adopts an advanced power system and transmission structure, which can complete the formation of particles with lower energy consumption.

7. Easy maintenance: The equipment has a compact structure and the design of each component is easy to maintain and repair. The replacement of vulnerable parts is simple and quick, and there is a sufficient supply of accessories on the market.

Organic fertilizer pellet machine is an advanced equipment specially used to process organic materials into granular fertilizer. It integrates modern machinery manufacturing technology and fertilizer production process requirements, aiming to provide efficient and high-quality fertilizer pellet manufacturing solutions for organic fertilizer production enterprises, agricultural cooperatives and related agricultural industries.

Compatible with multiple organic raw materials: It can process a variety of organic raw materials including but not limited to livestock and poultry manure, crop straw, biogas residue, urban organic waste, soybean meal, fungus residue, plant ash, etc. Whether it is a single raw material or a mixture of multiple raw materials, it can be granulated smoothly, allowing enterprises to make full use of the abundant local organic resources, flexibly adjust the fertilizer formula, and produce organic fertilizers rich in multiple nutrients.

Organic fertilizer pellet machine is widely used in the fields of organic fertilizer production, bio-fertilizer manufacturing, compound fertilizer processing, etc. It provides high-quality organic fertilizer pellet production equipment for various agricultural production enterprises, agricultural cooperatives, gardening fields, flower planting bases, etc., which helps to improve the quality of agricultural products, improve soil structure, reduce environmental pollution, and promote sustainable agricultural development.

The use of advanced granulation technology and efficient power transmission system can complete the granulation of a large amount of organic fertilizer in a short time, effectively improve production efficiency and meet the requirements of large-scale production. At the same time, the equipment runs stably, can achieve long-term continuous operation, reduce the number of shutdowns, and ensure the continuity of production.

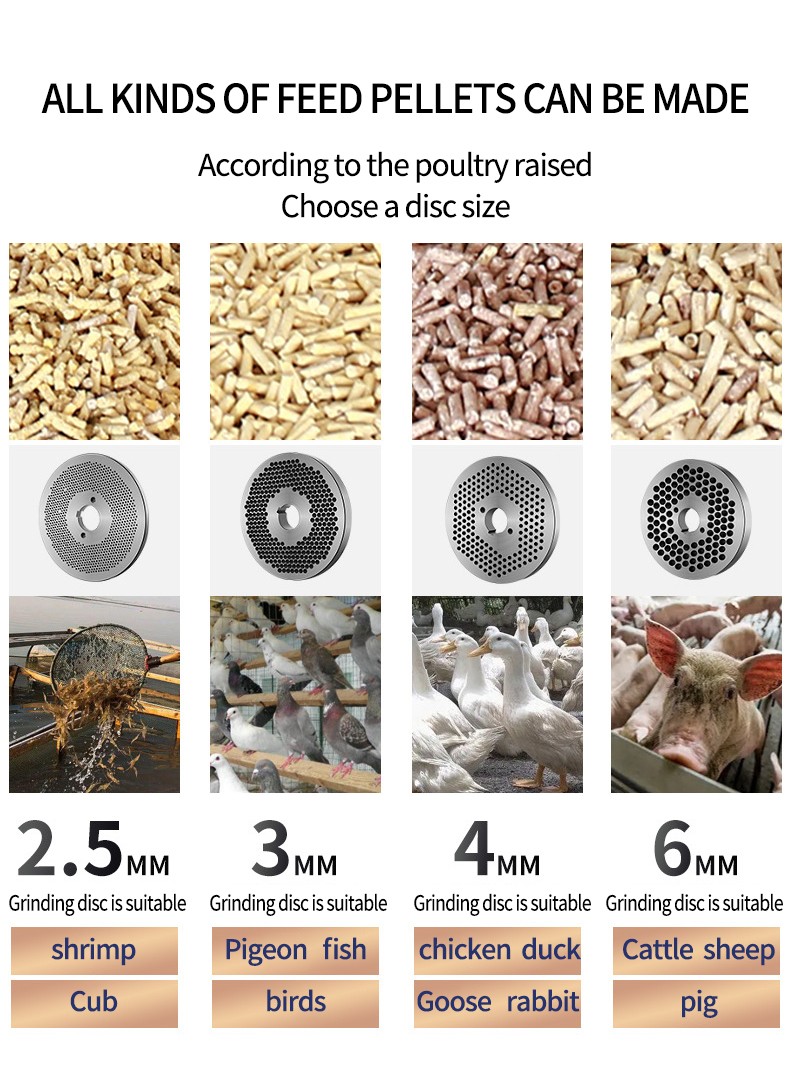

It can effectively process raw materials with different humidity, fiber content, and texture. The equipment is equipped with a special pre-treatment device, which can properly treat the raw materials according to their actual conditions to ensure the smooth progress of the granulation process. There is no need for complex pre-treatment procedures for the raw materials, which reduces production costs. Special fertilizers and feeds can be made according to different types of needs, and corresponding machine processing can be carried out to ensure demand.

Easy-to-maintain structural design: The structural design of the organic fertilizer pellet machine is compact and reasonable, and each component is easy to disassemble and install. The key components are made of wear-resistant materials to extend the service life of the equipment. The equipment is also equipped with a special maintenance channel and maintenance port to facilitate maintenance personnel to carry out daily maintenance and regular overhaul. The replacement of wearing parts is simple and quick, which can effectively reduce the downtime of the equipment and reduce maintenance costs.