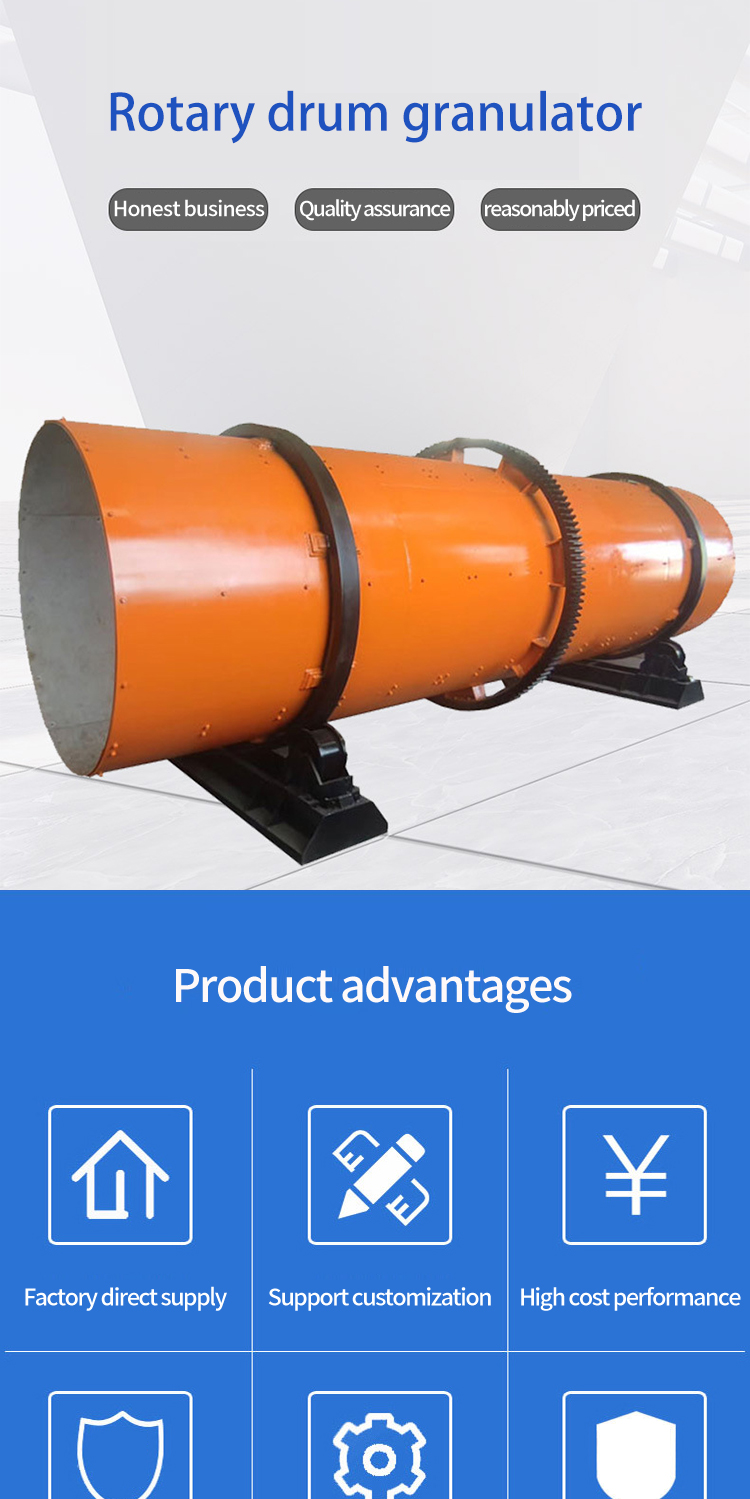

New Fertilizer Drum Granulator

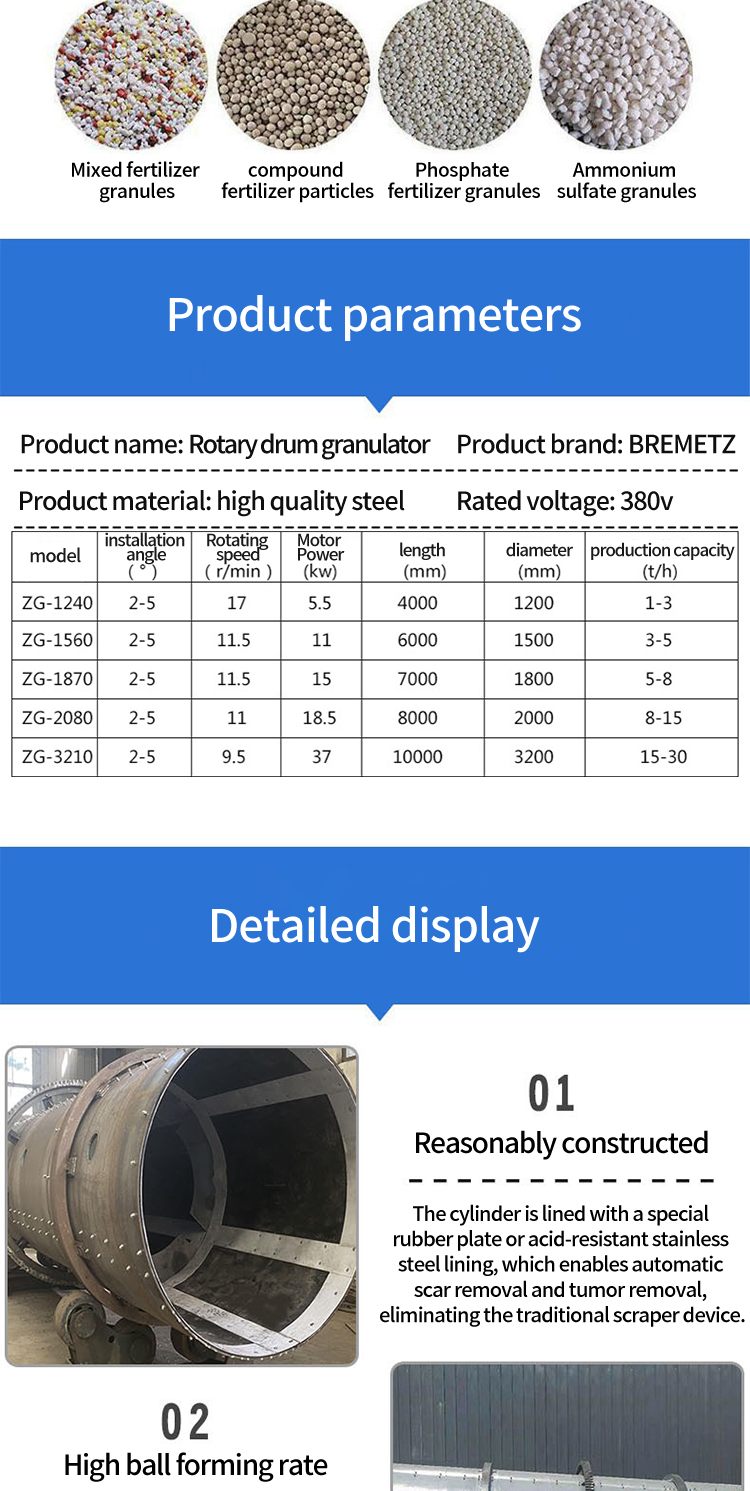

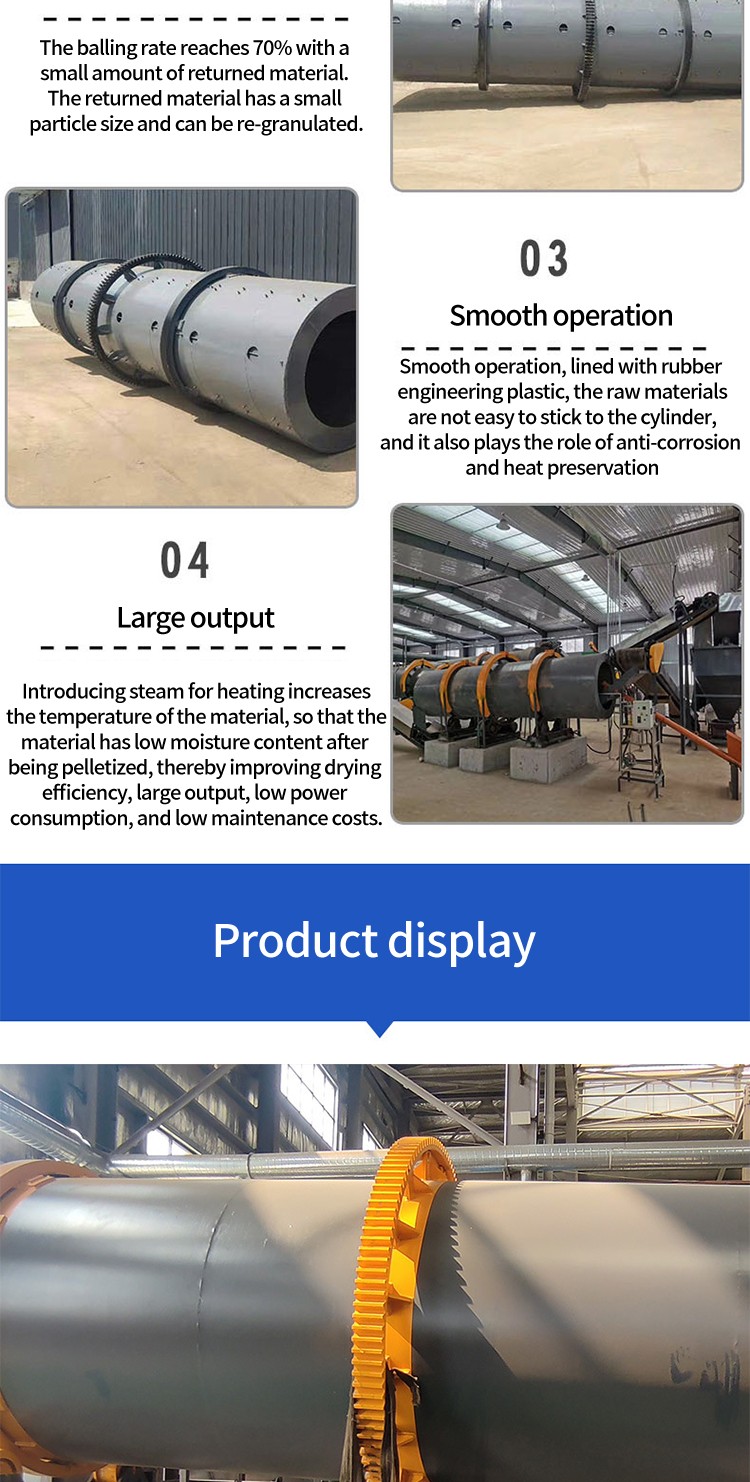

1. The drum rotates at high speed, and the materials complete the mixing and granulation process in a short time, greatly improving production efficiency.

2. By adjusting the drum speed, material formula and binder dosage, the shape and size of the fertilizer particles can be accurately controlled.

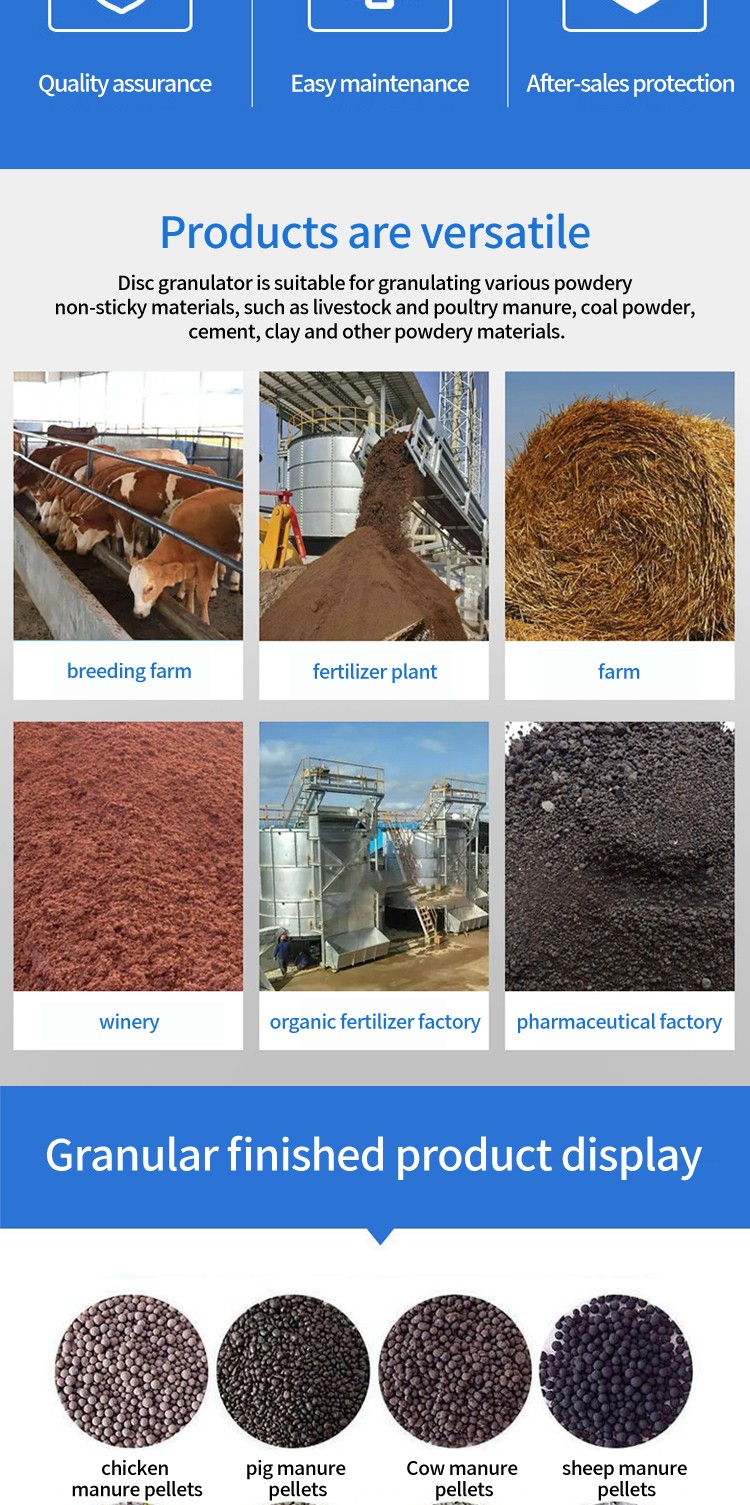

3. A variety of raw materials can be processed, whether it is a single raw material or a mixture of multiple raw materials, granular fertilizer can be effectively made.

4. The structure is simple, the equipment is easy to maintain, and the key components are made of wear-resistant materials with a long service life.

5. The closed design effectively reduces the emission of dust and odor, and reduces the pollution to the production environment and the surrounding atmosphere.

Made of high-quality carbon steel or stainless steel, it has good wear resistance and corrosion resistance. The inner wall of the drum has been specially treated to be smooth and not easy to stick to the material, ensuring that the material rolls smoothly in the drum and achieves efficient granulation.

The drum granulator has high production efficiency and can produce 2 tons of fertilizer granules per hour, which greatly improves the company's production capacity and meets the needs of large-scale production.

The fertilizer particles produced are regular and round in shape, uniform in size, high in strength, not easy to break, and have good fluidity and storage stability, which improves the commodity value of the product.

It is suitable for granulating a variety of fertilizer raw materials, such as nitrogen fertilizer, phosphate fertilizer, potash fertilizer, compound fertilizer, organic fertilizer, etc. It can meet the production requirements of fertilizers with different formulas and provide enterprises with a larger product research and development and production space.

The equipment has low energy consumption and can save 60% of energy consumption compared with traditional granulation equipment. At the same time, the closed design reduces the emission of dust and exhaust gas, reduces pollution to the environment, and meets environmental protection requirements.

Equipped with advanced automatic control system, the operator only needs to set the parameters on the console, and the equipment can automatically complete the entire production process including feeding, granulation and discharging.

The structure is reasonably designed, key components are easy to disassemble and replace, daily maintenance is simple, and the equipment failure rate is low, which can effectively reduce downtime and improve production efficiency.