Fully automatic Flat mold granulator

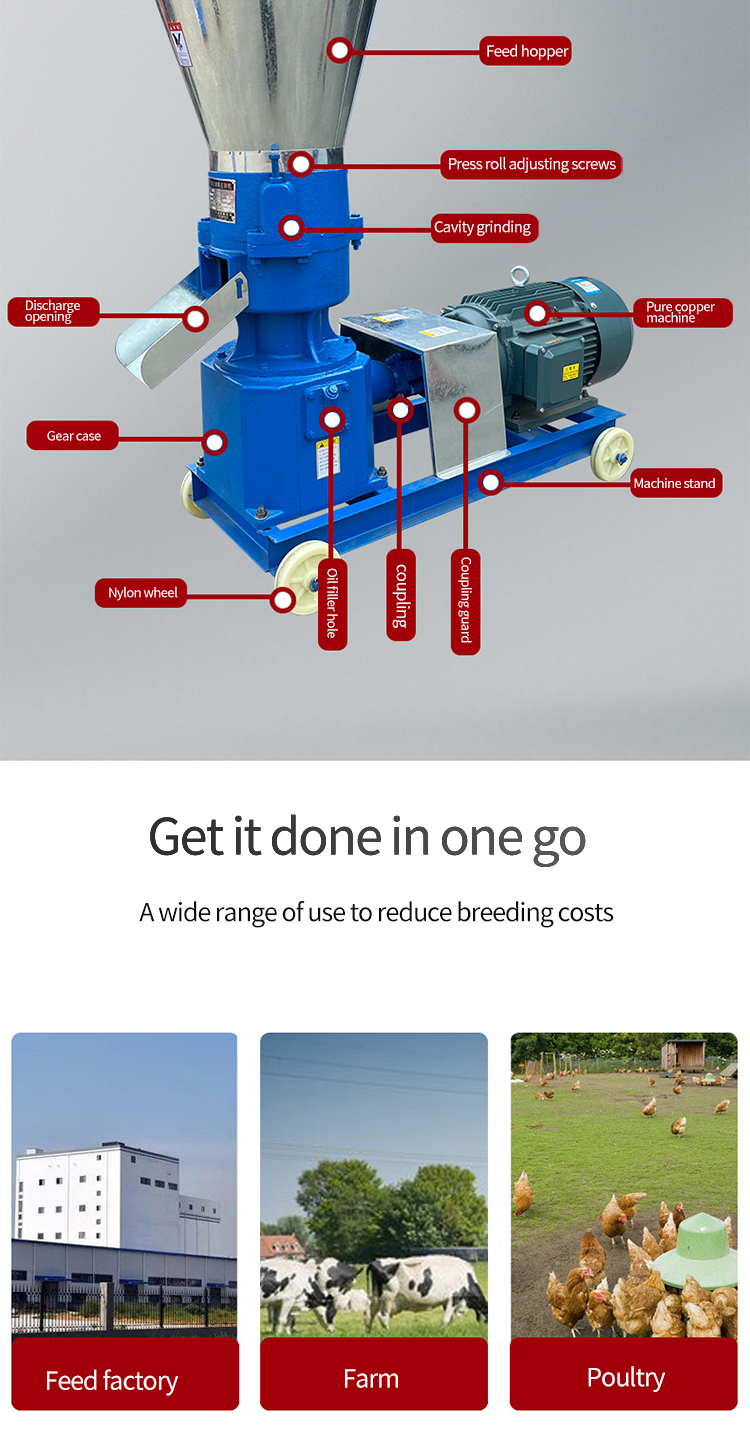

1. Adjustable mold gap: The screw center pressure adjustment mechanism allows the mold gap to be adjusted according to different materials, ensuring the pressing effect and applicable to a wider range of materials.

2. Pressure wheel pressure-bearing and wear-resistant: The pressure wheel body has a large groove width and can withstand greater pressure. Compared with other equipment, this design allows the pressure wheel to be repaired 2-3 times, further extending its service life.

3. Multiple pressure wheels are evenly distributed and run smoothly: The design of multiple pressure wheels evenly distributes makes the equipment run more smoothly, while increasing the pressing area and effectively improving production efficiency.

3. Diversified compression molding: By changing the mold, products of various shapes and sizes such as round bars, squares, and particles can be produced to meet the compression molding needs of different materials.

4. No need to dry: For some materials, when their moisture content is not lower than a certain standard, they can be directly pressed without drying the materials.

5. Automatic lubrication system: Equipped with a fully automatic lubrication system, it can ensure that all parts of the equipment are well lubricated, reduce wear, and reduce the occurrence of failures.

6. Good particle quality: The particles produced are uniform, smooth, round, high in strength, and good in fluidity.

The fully automatic flat die pelletizer is an advanced pelletizing equipment, which is widely used in many fields such as biomass energy, feed processing, chemical industry, fertilizer production, etc. It adopts advanced flat die design and automatic control system, which can efficiently and stably process various powdery or fibrous materials into high-quality pellet products.

Due to its unique flat die and pressure wheel design, as well as efficient transmission system, the equipment can achieve continuous and stable granulation operation with high production efficiency. Under appropriate material conditions and parameter settings, a large number of granular products can be produced per unit time to meet the needs of large-scale production.

The produced pellets have uniform size, smooth surface, high strength and good fluidity. For example, in feed pelleting, the pellets have a high degree of internal maturation and low loss of nutrients, which can effectively kill pathogenic microorganisms and parasites, improve the digestion and absorption efficiency of animals to feed, and ensure the healthy growth of animals; in the production of biomass pellets and chemical pellets, the high quality of the pellets is conducive to subsequent storage, transportation and use.

Through adjustable flat die gap and multiple die options, the equipment can adapt to different types of materials with different physical properties. Whether it is biomass materials with high fiber content, powdered feed or chemical raw materials, or sticky fertilizer raw materials, good granulation effects can be achieved on this equipment, without the need to purchase multiple special granulation equipment for different materials, reducing the equipment investment cost of the enterprise.

In the pelleting process, the efficient transmission of the equipment and the reasonable pressing process reduce energy waste and reduce energy consumption. In addition, for some materials, such as the pelleting of biomass raw materials, it helps to convert them into a more efficient form of energy, which has the significance of environmental protection and energy saving from the perspective of the entire industrial chain.

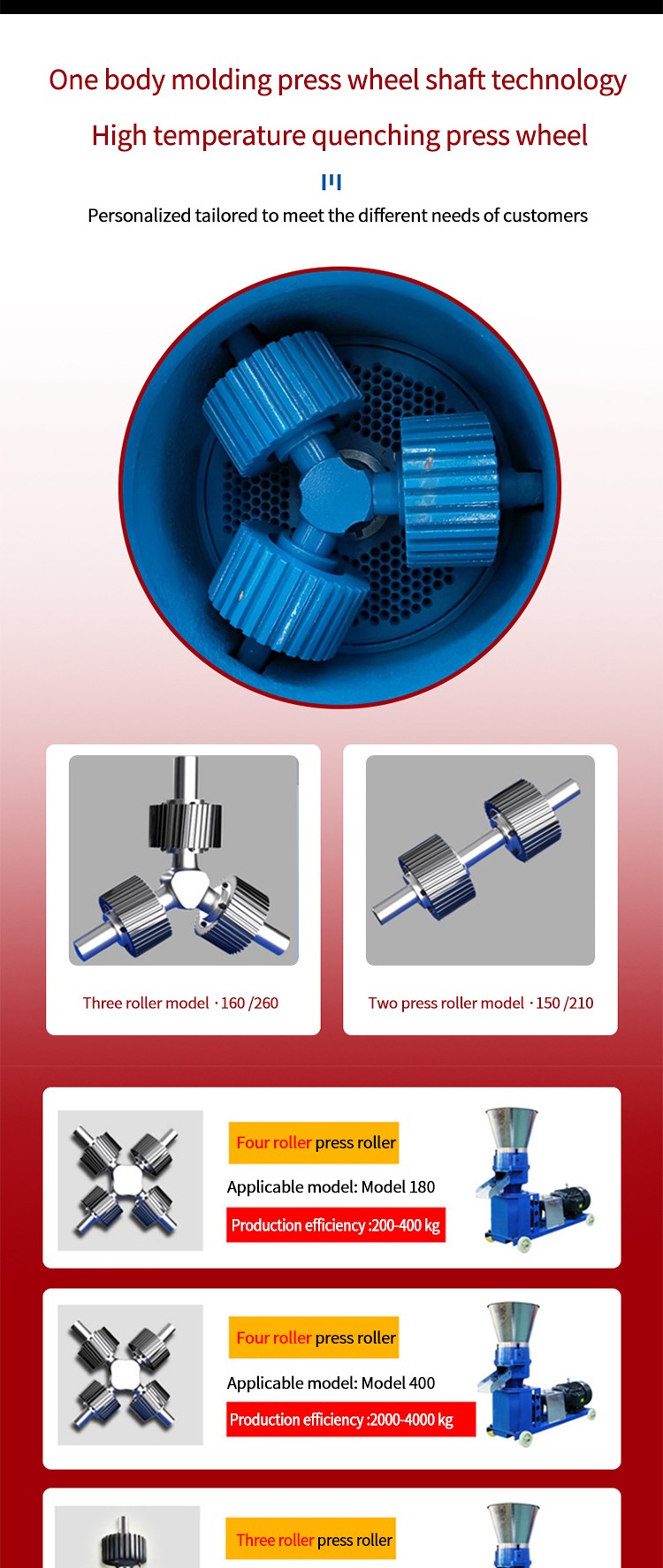

Personalized tailored to meet the different needs of customers

Three roller model. 160/260

Two press roller model 150/210

Four roller press roller

Applicable model: Model 180

Production efficiency:200-400 kg

Four roller press roller

Applicable model: Model 400

Production efficiency:2000-4000 kg

The key components such as bearings and oil seals in the transmission system are all imported high-quality products with good wear resistance, sealing and high temperature resistance. In addition, it is equipped with a lubrication return oil system and a thin oil circulation cooling lubrication system to provide sufficient lubrication and good heat dissipation conditions for the bearings, further improving the service life and stability of the transmission system.

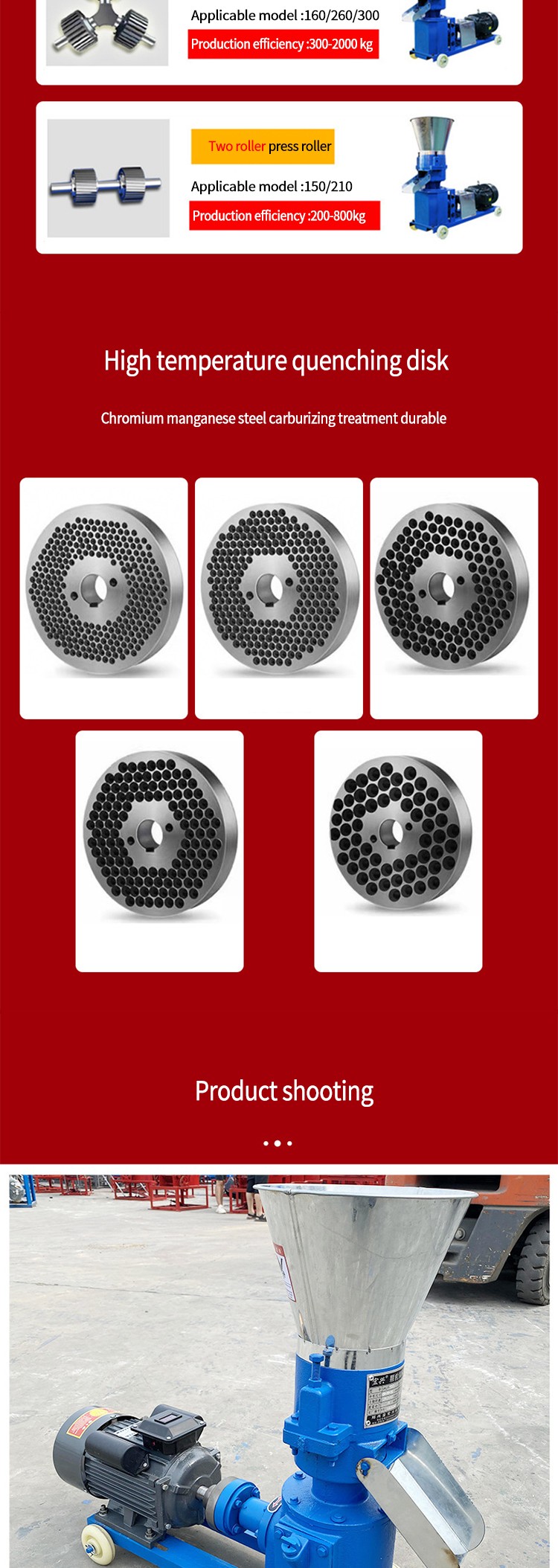

The flat die is made of high-strength, wear-resistant alloy steel material with good hardness and toughness. It can withstand long-term high pressure and material friction, extending the service life of the flat die.

Adjustable design: equipped with a screw center pressure adjustment mechanism, the gap between the flat die and the pressing wheel can be flexibly adjusted according to the characteristics of different materials to ensure the optimal pressure and density of the material during the pressing process, and ensure the molding quality and stability of the particles. At the same time, this design enables the equipment to adapt to a variety of different types of materials, expanding the application range of the equipment.

Including various wood processing wastes (such as wood chips, sawdust), crop straw (such as rice husks, wheat straw, corn straw, cotton stalks, etc.), weeds, etc. These biomass raw materials can be used as biomass fuels after pelleting to replace traditional fossil energy, with the advantages of environmental protection and renewable. At the same time, biomass pellets can also be used as part of animal feed for the feeding of ruminants.