Flat die pelletizer

1. The flat die pelletizer usually has a simple structure, compact overall layout, small space occupation, and is relatively easy to install and maintain.

2. Its operation process is relatively intuitive and easy to master, and operators can operate it proficiently after simple training.

3. It can handle many different types of materials. For materials with different humidity, particle size and viscosity, the flat die pelletizer can achieve better pelletizing effect by adjusting parameters.

4. The pellets produced by the flat die pelletizer have regular shape, smooth surface, and high uniformity of particle size.

5. The pellets extruded by the flat die pelletizer have high density and strength, and are not easy to break and pulverize during storage, transportation and use.

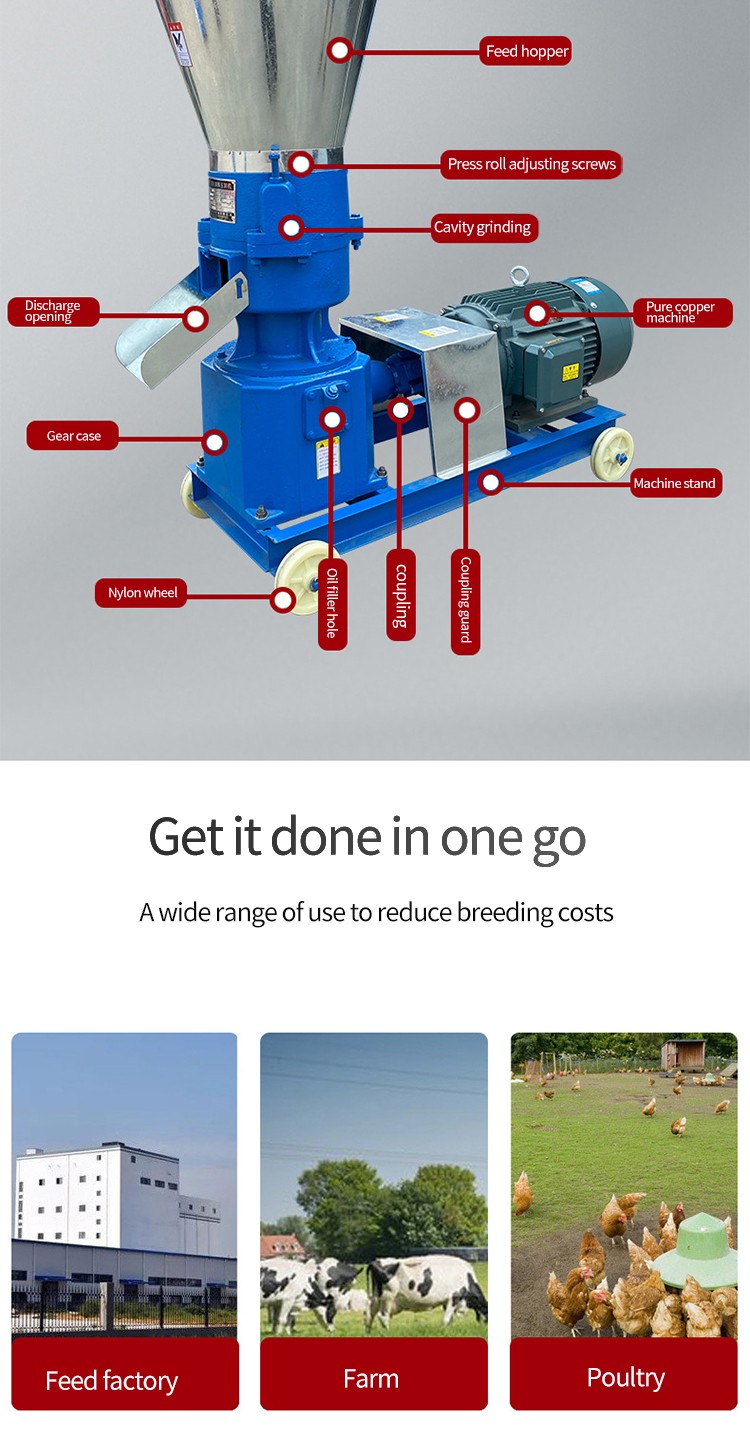

Transmission system: belt and worm gear two-stage transmission is often used, which runs smoothly and has low noise.

Feeding system: Feeding by the material's own gravity can avoid blockage.

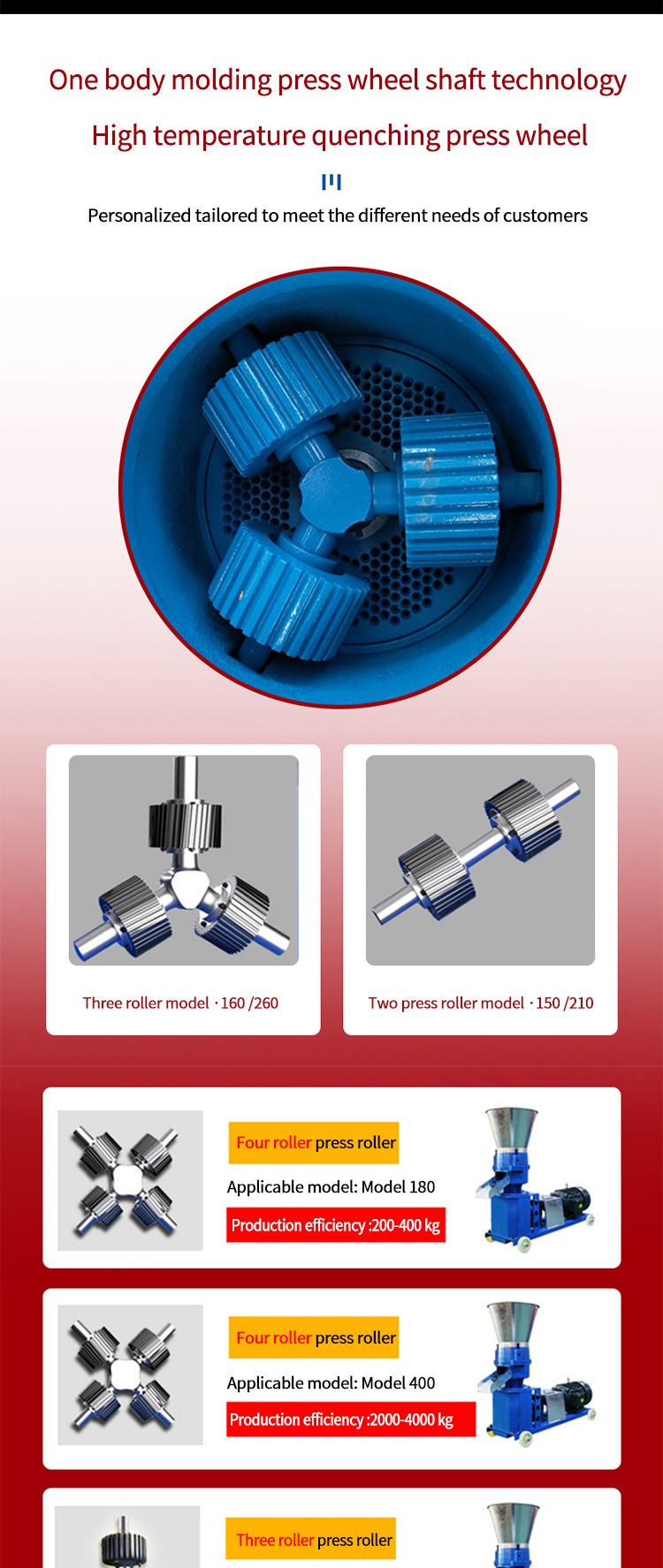

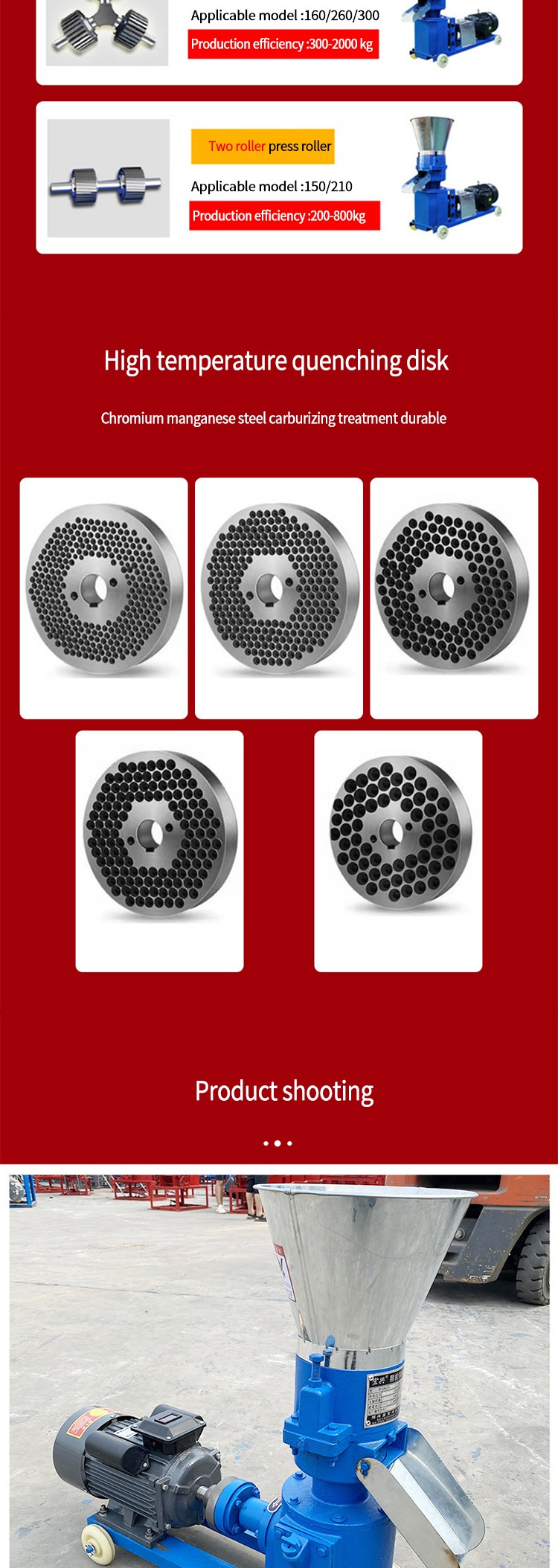

Pressing system: It consists of a flat die and a pressing roller. The diameter of the pressing roller is not limited by the diameter of the flat die, which can increase the inner shaft space. Large bearings are used to enhance the bearing capacity of the pressing wheel and improve the pressing force.

Adjustment system: It adopts the threaded column center adjustment mechanism, which can manually rotate or hydraulically automatically adjust the gap between the pressure roller and the flat die.

Feed processing: Corn, soybean meal, wheat bran and other raw materials can be made into pellet feed, which is suitable for all kinds of livestock and poultry breeding. Biomass energy: Biomass materials such as wood chips, straw, rice husks can be made into biomass pellet fuel for combustion heating, power generation, etc.

Organic fertilizer production: Fermented organic materials can be directly made into organic fertilizer granules to improve fertilizer utilization efficiency and market value.

Strong material adaptability: It can process materials with high fiber content, such as straw, sawdust, etc., and can also process materials with high oil and sugar content.

Good particle quality: The produced particles have smooth surface, regular shape, uniform size, high particle density and strength, and are not easy to break or pulverize during storage and transportation.

Low energy consumption: Compared with some granulating equipment, it has low power, small mechanical loss during operation, and less power input for processing the same output of materials.

Easy operation and maintenance: simple structure, few parts, intuitive and easy operation, and convenient for maintenance personnel to inspect, repair and replace parts.

Other fields: In the chemical, pharmaceutical and other industries, it is used to make some powdered raw materials into granular products for easy storage, transportation and use.