Disc granulator

1. High particle quality: The disc granulator can produce particles with regular shape and uniform particle size. Through reasonable process parameter control, the sphericity of the particles can be high and the surface can be smooth, which reduces the particle breakage rate and pulverization phenomenon.

2. Adjustable particle size: It has good particle size adjustment ability. By adjusting the parameters such as the rotation speed, inclination angle, material residence time and the amount of binder added of the disc, the size of the produced particles can be accurately controlled.

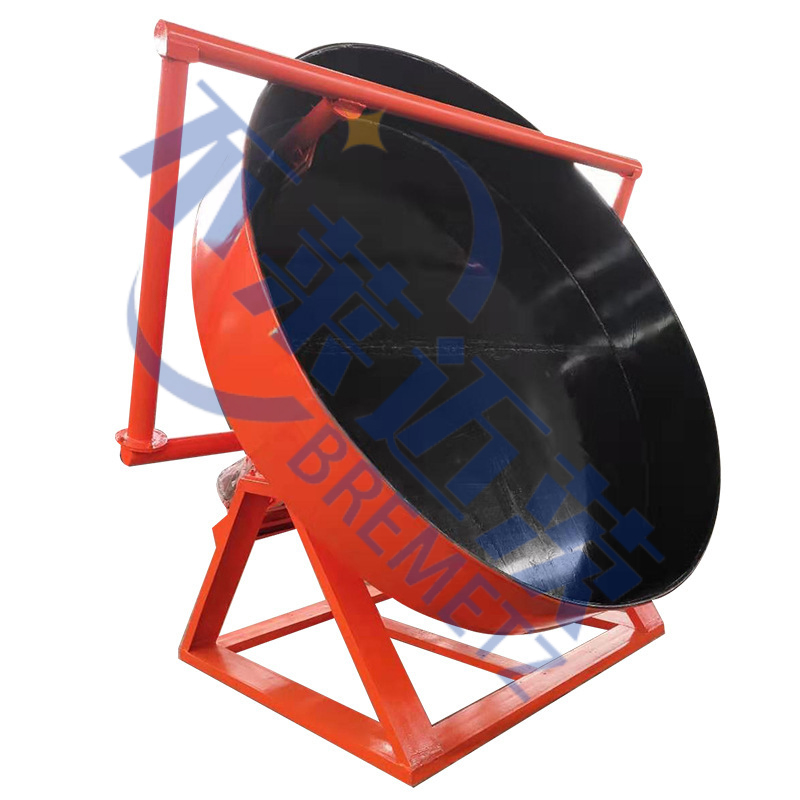

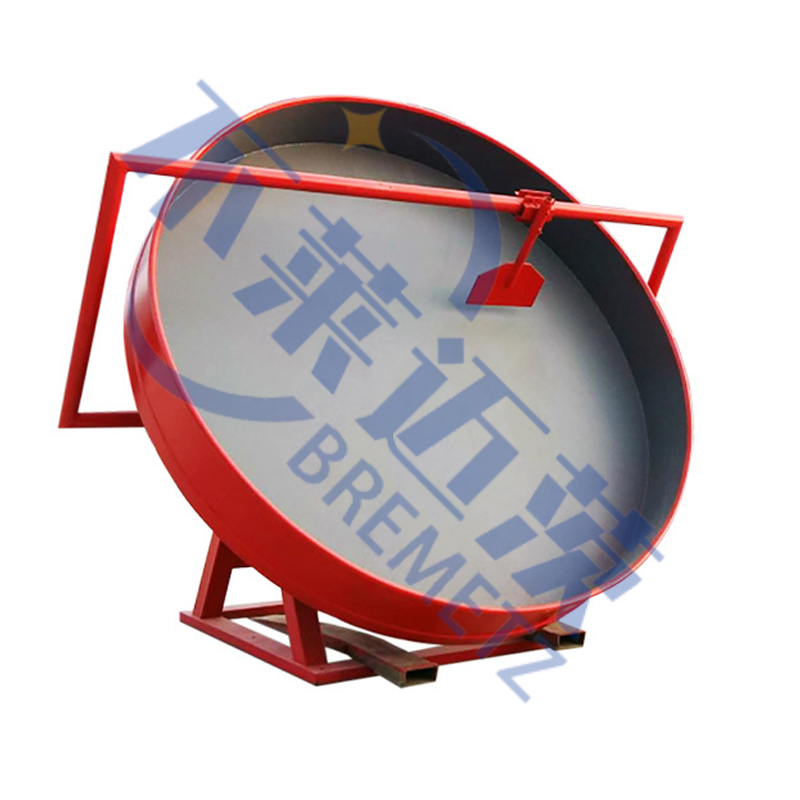

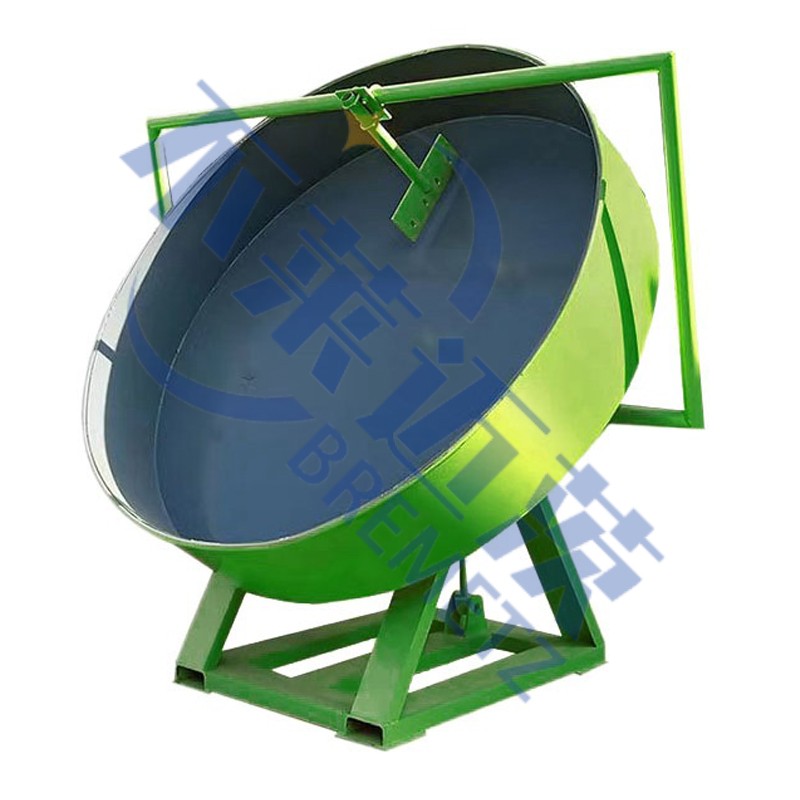

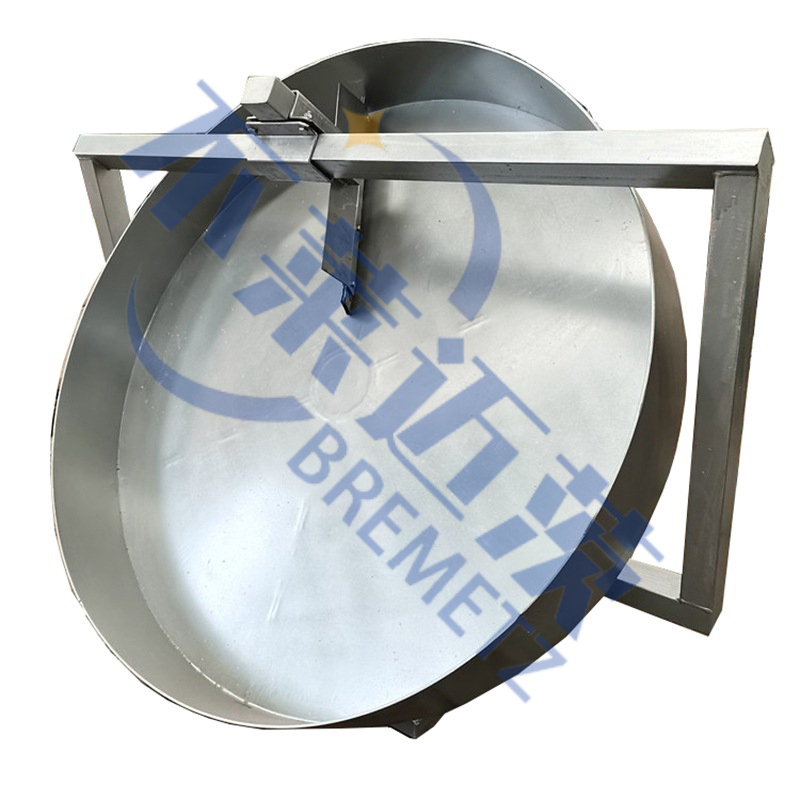

3. Simple and easy to understand structure: Its structure is relatively simple, mainly composed of discs, drive devices, brackets and other parts. Operators can easily understand its working principle and structural characteristics, which makes the operation and maintenance training cost of the equipment low.

4. Continuous and stable operation: The disc granulator can operate continuously and stably for a long time. Its drive system and transmission components have been carefully designed and optimized to ensure the stable rotation of the disc and reduce the downtime caused by mechanical failure.

5. Output scalability: It has a certain output scalability. By selecting a disc of appropriate size and optimizing the production process, the output can be increased within a certain range.

6. Strong material compatibility: It can handle a variety of materials of different properties. In fertilizer production, it can handle various fertilizer raw materials; in the chemical industry, it can granulate powders with different chemical compositions; in the food and pharmaceutical industries, it can also adapt to the corresponding raw material characteristics.

7. Economical operation cost: During operation, the disc granulator has relatively low energy consumption. The power of its driving motor is reasonably configured according to the size of the equipment, and it will not consume too much electricity.

Disc granulator is a kind of granule manufacturing equipment widely used in many industries such as chemical industry, fertilizer, food, pharmaceutical, etc. It aggregates powdery or fine granular materials into granules with a certain size and strength through the unique disc rotation motion, providing high-quality and uniform granule products for various industries to meet different production processes and market needs.

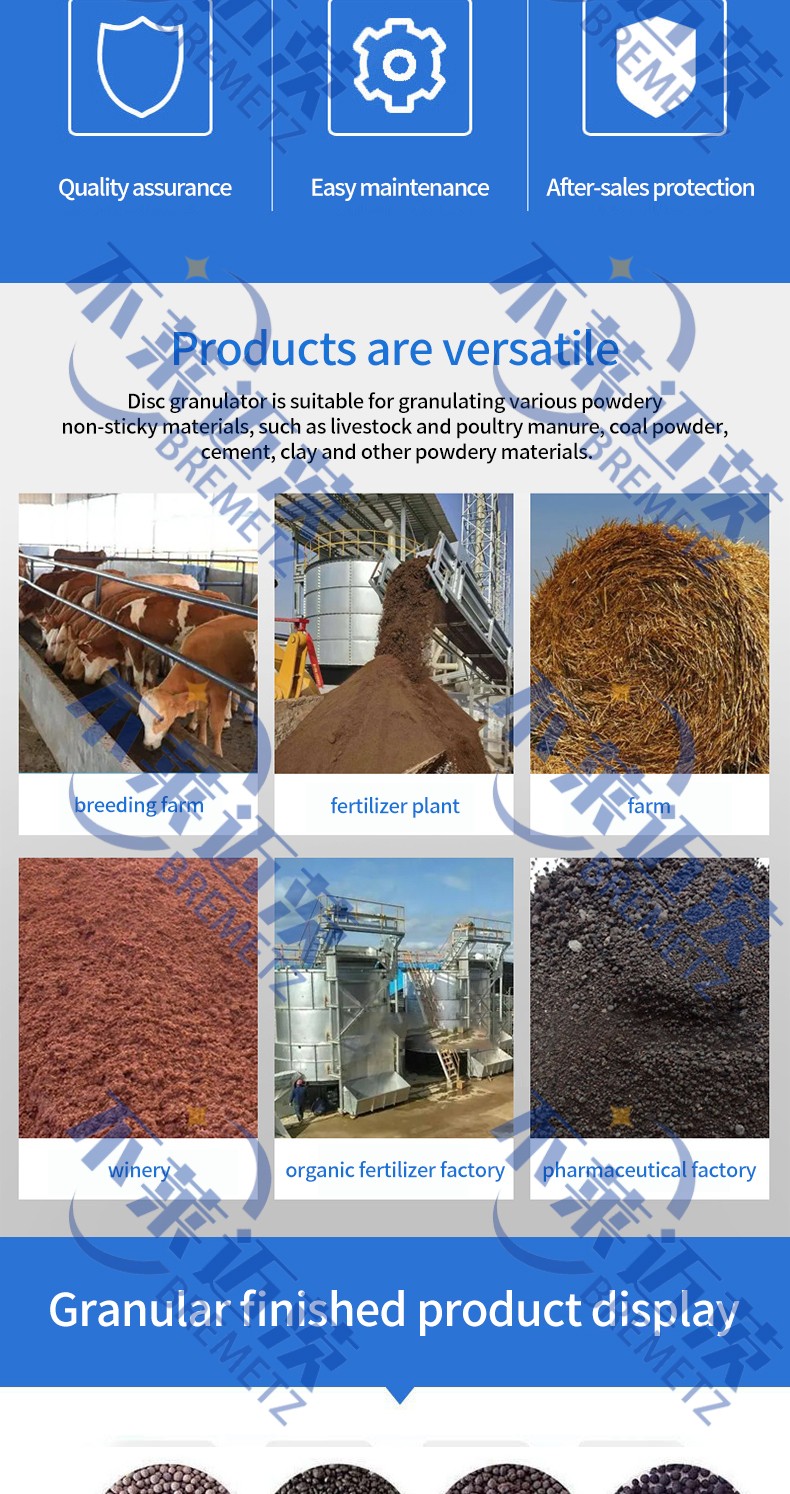

Products are versatile:

Disc granulator is suitable for granulating various powdery non-sticky materials, such as livestock and poultry manure, coal powder,cement, clay and other powdery materials.

breeding farm,fertilizer plant,farm,winery,organic fertilizer factory,pharmaceutical factory pharmace.

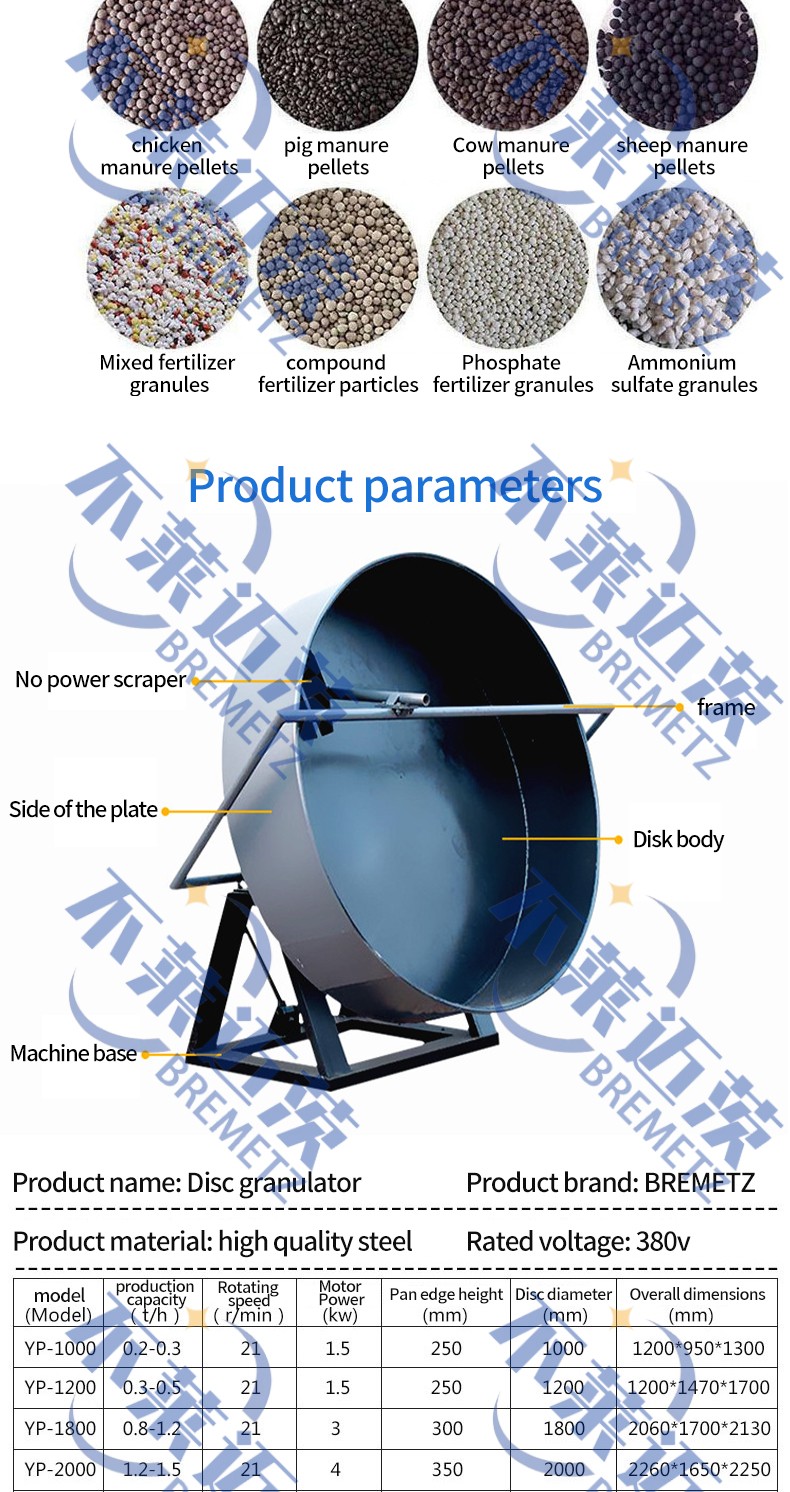

Product name: Disc granulator

Product material: high quality steel

Product brand: BREMETZ

Rated voltage: 380v

model (Model):YP-1000,YP-1200,YP-1800,YP-2000

production capacity (t/h):0.2-0.3,0.3-0.5,0.8-1.2,1.2-1.5

Rotating (r/min) speed:21,21,21,21

Motor Power (kw):1.5,1.5,3,4

Pan edge height:(mm):250,250,300,350

Disc diameter (mm):1000,1200,1800,2000

Overalldimensions(mm):1200*950*1300,1200*1470*1700,2060*1700*2130,2260*1650*2250

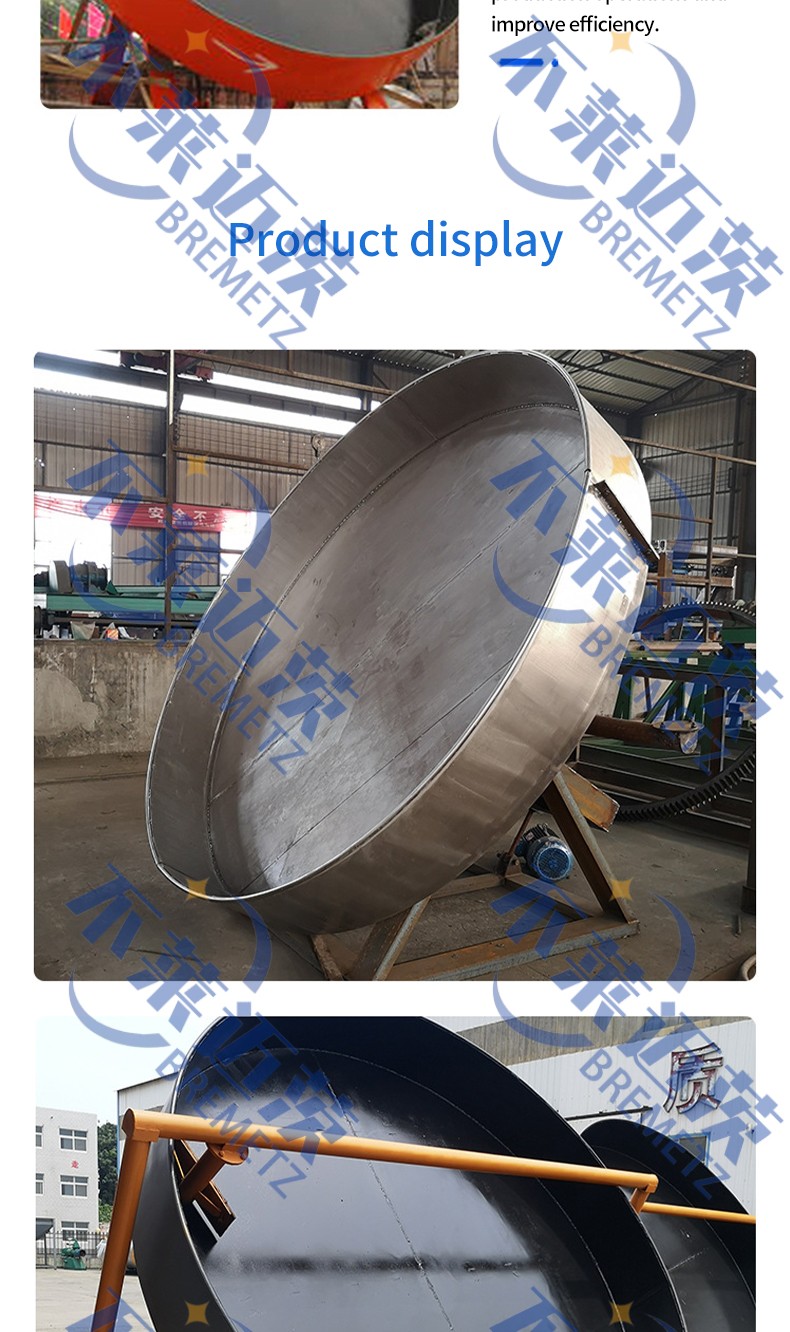

Even granulation,The granulated particles are uniform, smooth and round, and the particle forming rate reaches more than 93%.

running stable,Adopting flexible belt drive, smooth starting and long service life.

High cost performance,The granulating plate is equipped with three discharge ports to facilitate intermittent production operations.

The disc granulator has good continuous operation performance. Its stable drive system and reliable mechanical structure ensure that the equipment can work uninterruptedly for a long time, reduce the number of shutdowns in the production process, and improve production efficiency. In large-scale industrial production, it can meet the needs of high output.

The disc granulator is designed to be easy to maintain. Its main components are easy to disassemble and install, which is convenient for daily inspection, cleaning and maintenance. For example, the inside of the disc can be cleaned regularly to prevent material residue and adhesion; the motor and reducer of the drive system are also easy to maintain and service, which reduces the maintenance cost and repair time of the equipment.