Fertilizer granulator

1. High productivity output: It has strong production capacity and can produce a large amount of fertilizer granules per hour, easily meeting the needs of large-scale fertilizer production. Whether it is to cope with the surge in demand in the peak season or to provide sufficient fertilizer supply for large-scale agricultural projects, it can be used with ease.

2. Continuous and stable operation: Advanced design and high-quality parts are used to ensure that the equipment can operate continuously and stably for a long time, reducing downtime and the risk of production interruption. Improved overall production efficiency and reduced unit production costs.

3. Optimize energy utilization: By using efficient transmission systems and advanced motor technology, energy consumption during equipment operation is significantly reduced. It can save a lot of electricity and save energy costs for enterprises.

4. Reduce energy consumption: The fertilizer granulator adopts a unique normal temperature granulation process, eliminating the need for additional drying equipment and energy consumption. It not only simplifies the production process, but also avoids energy loss and degradation of raw material quality caused by the drying process.

5. Compatible with a variety of chemical fertilizer raw materials: Whether it is common nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, or various compound fertilizers, trace element fertilizers, etc., it can be granulated smoothly on this granulator.

6. Loose requirements for raw material humidity: It can adapt to changes in raw material humidity within a certain range. For some raw materials with higher moisture content, it can be directly granulated without excessive pretreatment. Through unique process design, problems such as particle adhesion and molding difficulties caused by excessive moisture can be effectively avoided.

Fertilizer granulator (also known as three-in-one granulator) is a molding machine that makes materials into specific shapes. It is one of the key granulation equipment for compound fertilizer and organic fertilizer processing and production. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The main working mode is wet granulation of granules. Through a certain amount of water or steam, the base fertilizer is fully chemically reacted in the cylinder after humidity adjustment, and the extrusion force is generated to make the granules agglomerate into balls. The cylinder of the machine adopts a special rubber sheet lining or acid-resistant stainless steel lining to realize automatic scar and tumor removal. The machine has the characteristics of high ball strength, good appearance quality, corrosion resistance, wear resistance, and low energy consumption.

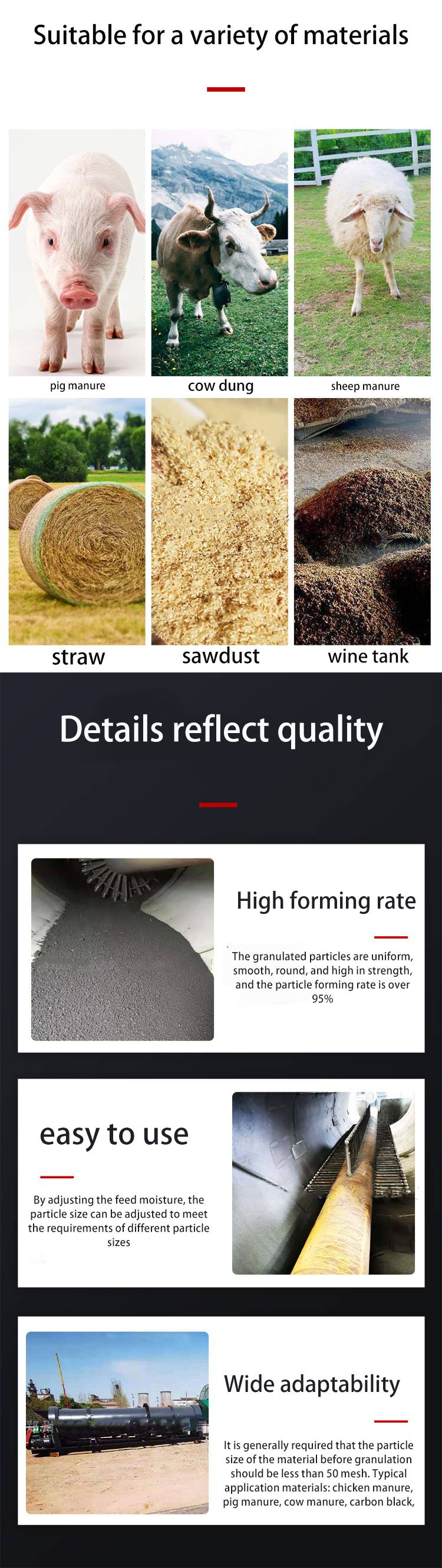

Applicable to a variety of materials: pig manure, cow manure, sheep manure, straw, sawdust, wine cans.

Easy to use: By adjusting the moisture content of the feed, the particle size of the output can be adjusted to meet the requirements of different particle sizes.

High forming rate: The granulated particles are uniform, smooth, round, and have high strength. The particle formation rate is more than 95%.

Wide adaptability: Generally, the particle size of the material before granulation is required to be less than 50 mesh. Typical application materials: chicken manure, pig manure, cow manure, carbon black.

Application areas: In the agricultural field, it is used to produce various granular products of single-element fertilizers such as nitrogen, phosphorus, potassium, and compound fertilizers. The powdered or liquid fertilizer raw materials are processed into granules by a granulator for easy storage, transportation and application.

Organic fertilizer production: With the development of organic agriculture, the demand for organic fertilizers is increasing. Fertilizer granulators can make organic fertilizer granules from organic waste such as livestock and poultry manure, straw, and biogas residues after fermentation.

Chemical industry: Some fertilizer-related products or intermediates are produced in the chemical industry, and fertilizer granulators are also needed.

Pharmaceutical industry: In the pharmaceutical field, the production process of some drugs may involve processes similar to fertilizer granulation.

Feed industry: In feed production, various feed raw materials need to be mixed and granulated to improve the palatability, digestibility and storage of feed.

Environmental protection industry: Fertilizer granulators are also used in some environmental protection projects.

Fertilizer granulator has become a key equipment in the field of fertilizer production with its many advantages such as efficient production, energy saving and consumption reduction, excellent granulation quality, simple operation, strong adaptability of raw materials and environmental protection. It not only promotes the technological progress and industrial upgrading of the fertilizer industry, but also provides strong support for the modernization of agriculture. Choosing an advanced fertilizer granulator means choosing an efficient, high-quality and environmentally friendly fertilizer production method, creating greater value for the enterprise and contributing more to agricultural development.