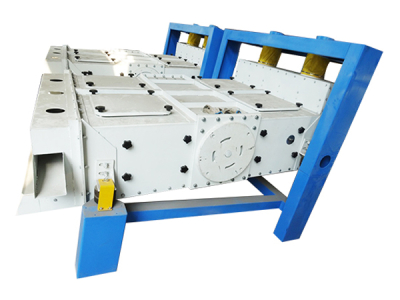

Disc granulation equipment

1. The reducer and the motor are driven by flexible belts, which start smoothly, reduce the impact force and increase the service life of the equipment.

2. The bottom of the granulator disc is reinforced with multiple radiating steel plates, which is sturdy and durable.

3. The thickened, heavier and sturdy base design does not require anchor bolts to fix it, and runs smoothly.

4. The main gear of the granulator adopts high-frequency quenching, and its service life can be doubled.

5. The equipment granulates evenly and has a high balling rate.

Breimaitz mechanical disc granulator is mainly used for granulating organic fertilizer. It is simple to operate, has a high ball forming rate and low investment cost. The powdered organic fertilizer is transported to the ball forming disc by the conveyor belt. Under certain humidity conditions, it is continuously rolled into granular fertilizer through the action of centrifugal force, friction and gravity, and then discharged from the discharge port.

Frame part: The frame part of the disc granulator is welded by high-quality channel steel, which can provide good support for the entire equipment. The transmission part and the rotating working part of the whole machine are supported by the frame.

Adjustment part: The adjustment part is mainly welded by carbon steel plate and channel steel, which is one of the important components of the operation of the granulator disc.

Transmission part: The transmission part is the core part of the whole machine operation. The motor and reducer used in it are all in cooperation with well-known brands, and the quality is guaranteed. The motor drives the pulley, V-belt, reducer and pinion, and the pinion drives the large gear on the granulation disk to make the granulation disk work.

Granulation disk: The granulation disk is an important place for powdered organic fertilizer to become granular organic fertilizer. The entire disc corner adopts an arc design, the bottom is reinforced by multiple radiating steel plates, and three discharge ports are also set.

Stable operation and energy saving: The mechanical transmission components are mature and reliable. After reasonable design and debugging, they run smoothly, with small vibration and few failures. They have a long service life under normal maintenance. The energy consumption of the equipment is mainly concentrated in the motor drive disc. There are not too many complex energy-consuming links. The overall energy consumption is at a low level, and the energy-saving benefits of long-term operation are obvious.

Controllable investment cost: Compared with some high-end drum granulation and spray granulation equipment, disc granulation equipment has a relatively simple structure, low manufacturing and procurement costs, low requirements for supporting equipment, and is more affordable in terms of investment in infrastructure such as site and electricity. It is suitable for the initial investment and production capacity start-up of small and medium-sized fertilizer production enterprises.