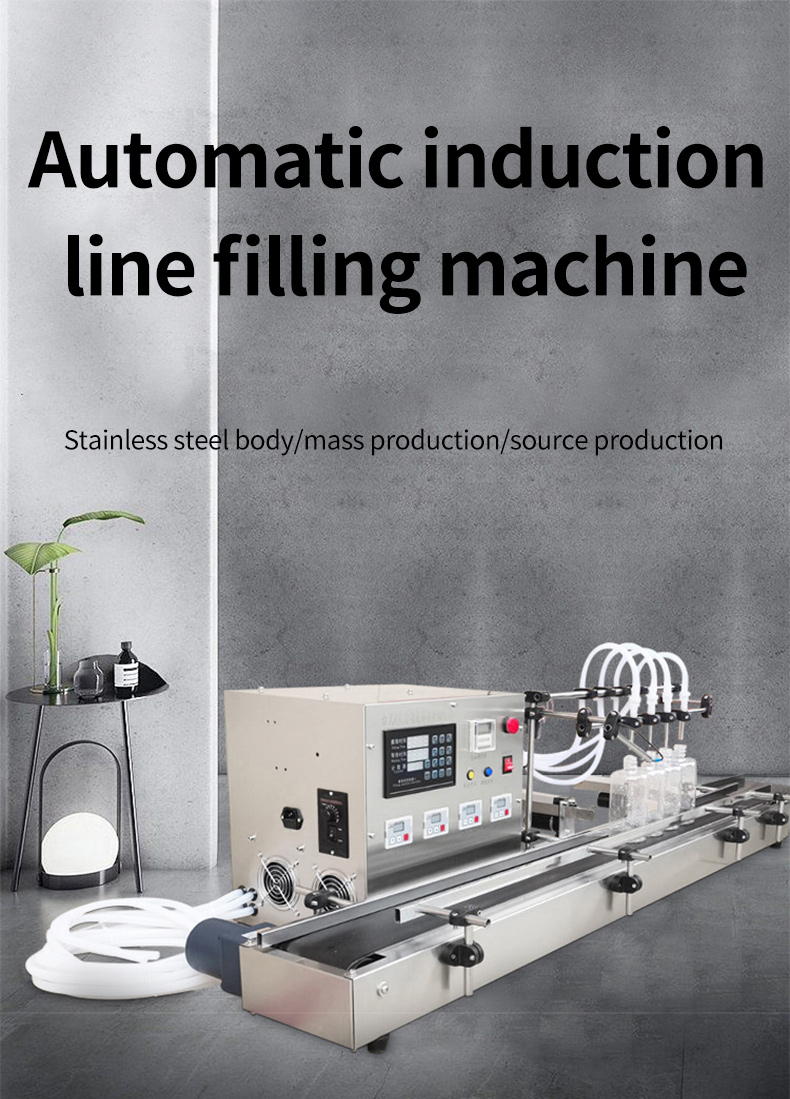

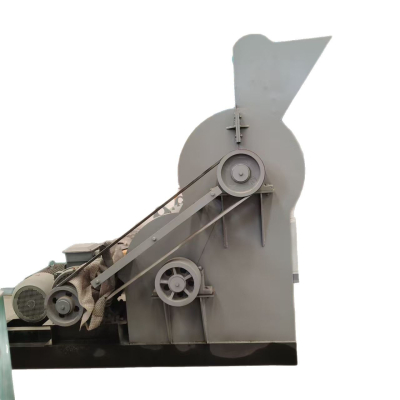

Automatic induction line filling machine

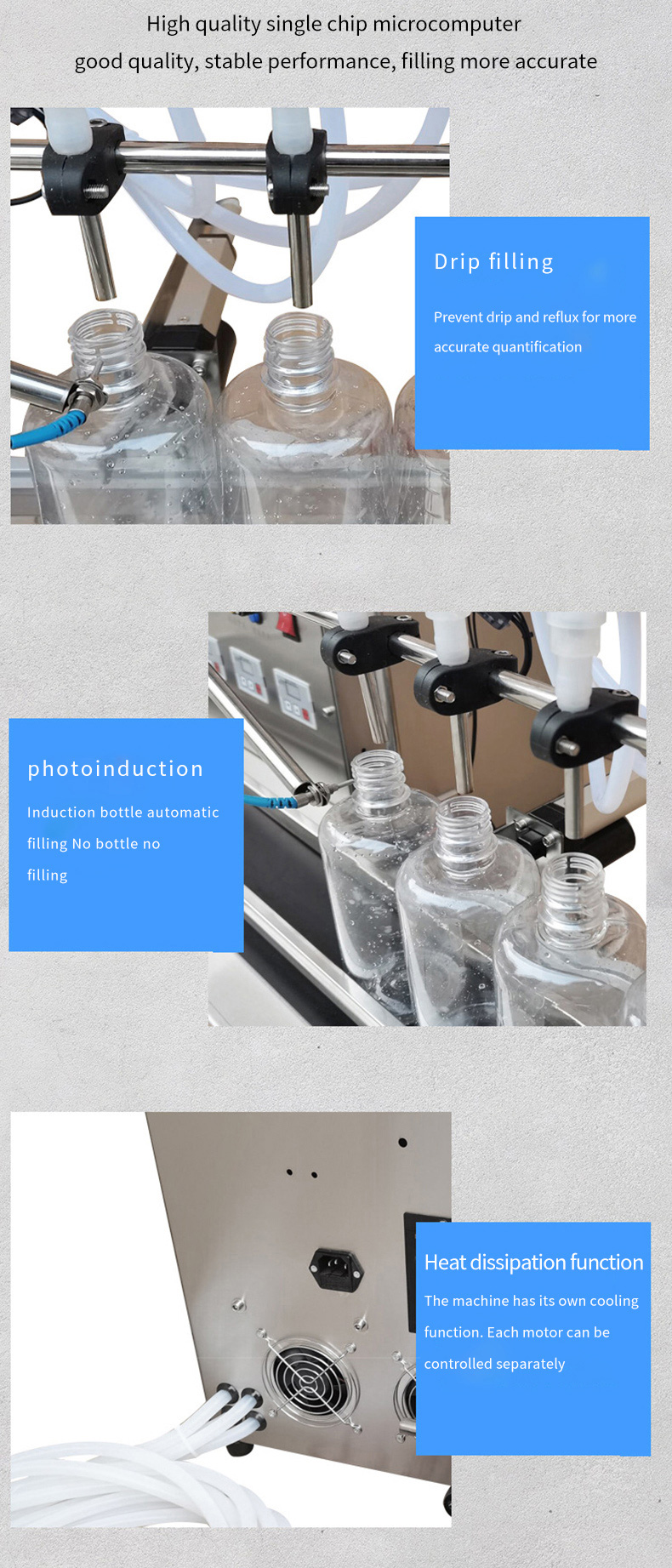

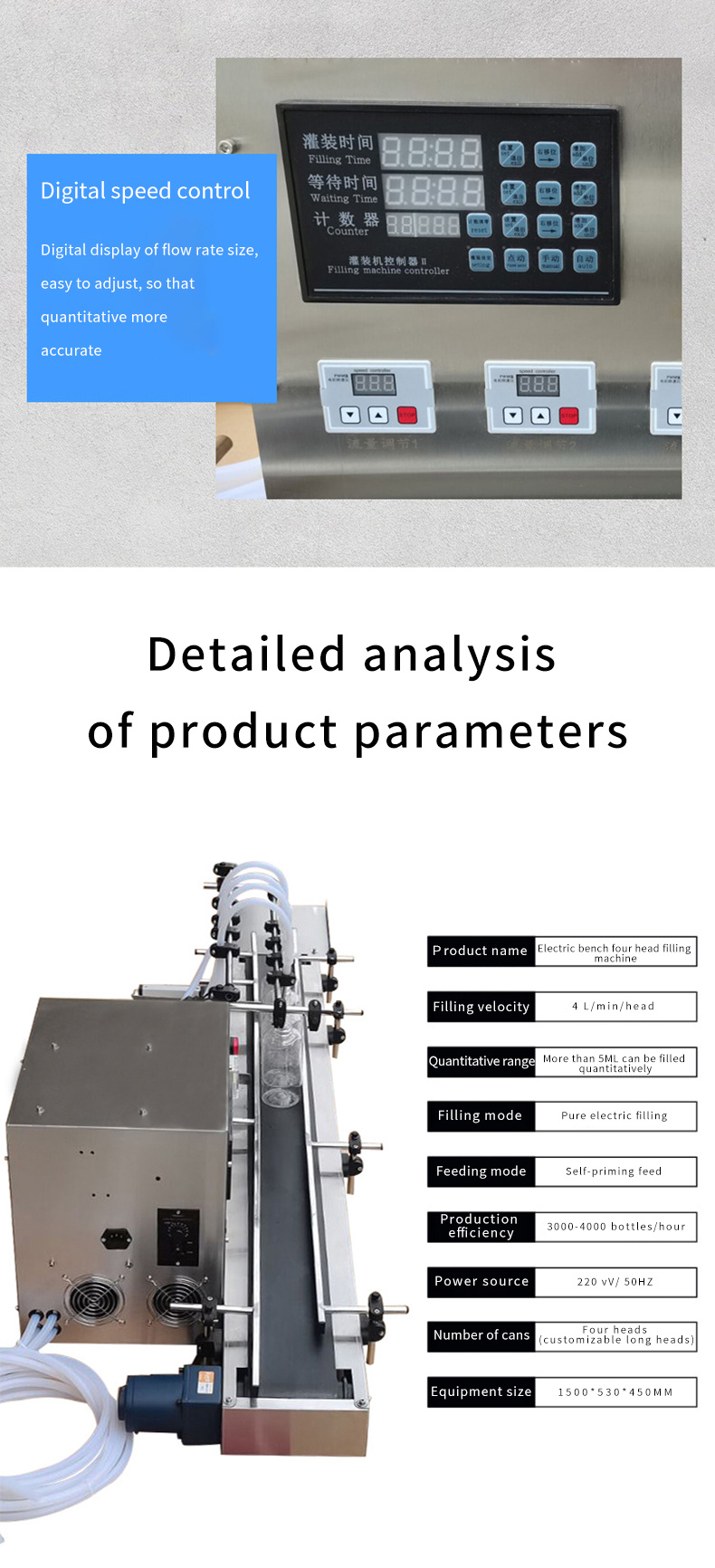

1. Equipped with advanced sensing technology and precise metering system, it can accurately control the filling volume and ensure that the filling volume of materials in each container is highly consistent.

2. During long-term continuous operation, it can still maintain stable filling accuracy and is not disturbed by external factors.

3. With a high filling speed, it can complete the filling task of a large number of products in a short time, significantly improving production efficiency.

4. It can adapt to containers of different shapes and sizes. Simply adjust the equipment parameters or replace some accessories to achieve the filling of containers of different specifications.

5. When producing different products or changing container specifications, equipment adjustments and conversions can be completed quickly, reducing equipment downtime.

The automatic induction line filling machine is a highly efficient automatic filling equipment that integrates advanced technology. It uses a high-precision induction system combined with an intelligent control system to accurately and quickly fill various liquids, pastes or semi-fluid materials.

With advanced sensing technology and precise metering system, it can achieve extremely high filling accuracy, and the filling volume error can be controlled between ±0.1% - ±0.5%.

It has a fast filling speed and can fill dozens to hundreds of containers per minute according to different material properties and container specifications.

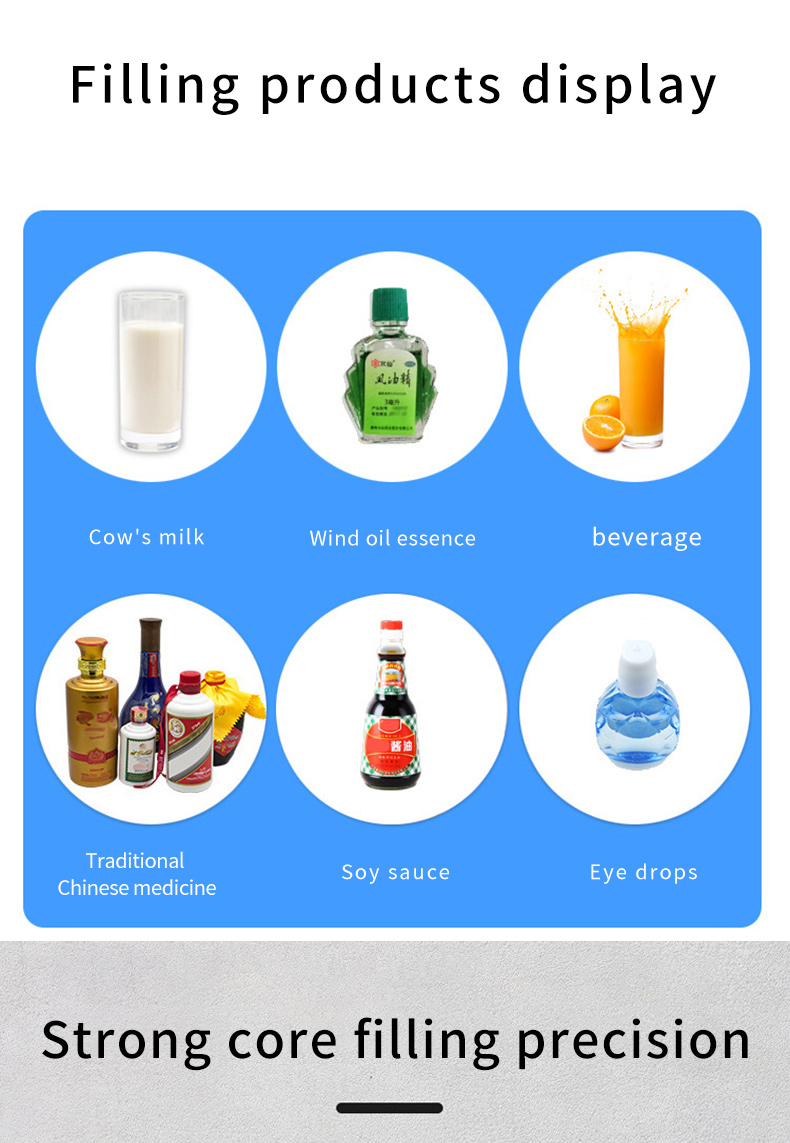

It can adapt to containers of different shapes, sizes and materials. Whether it is round bottles, square boxes, special-shaped cans, or glass containers, plastic containers, or metal containers, all can be filled on this filling machine.

The intelligent control system and automated sensing device are used to achieve fully automated operation of the equipment. From container transportation, positioning, filling to finished product output, the entire process does not require human intervention, reducing the impact of human factors on production and improving production efficiency and product quality stability.

The whole machine is made of stainless steel, and the parts in contact with the materials meet the food grade or medical grade hygiene standards. They are easy to clean and disinfect, and can effectively prevent material contamination and cross infection.