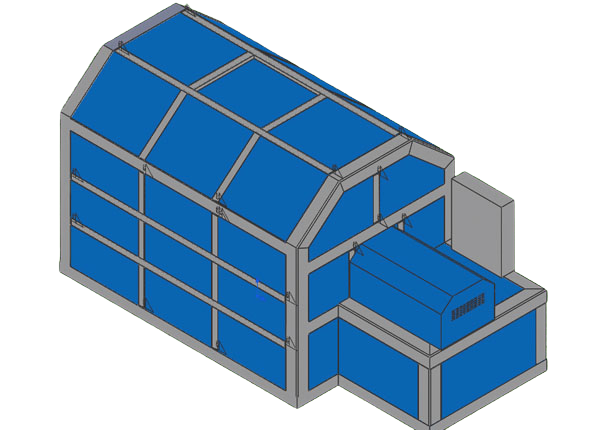

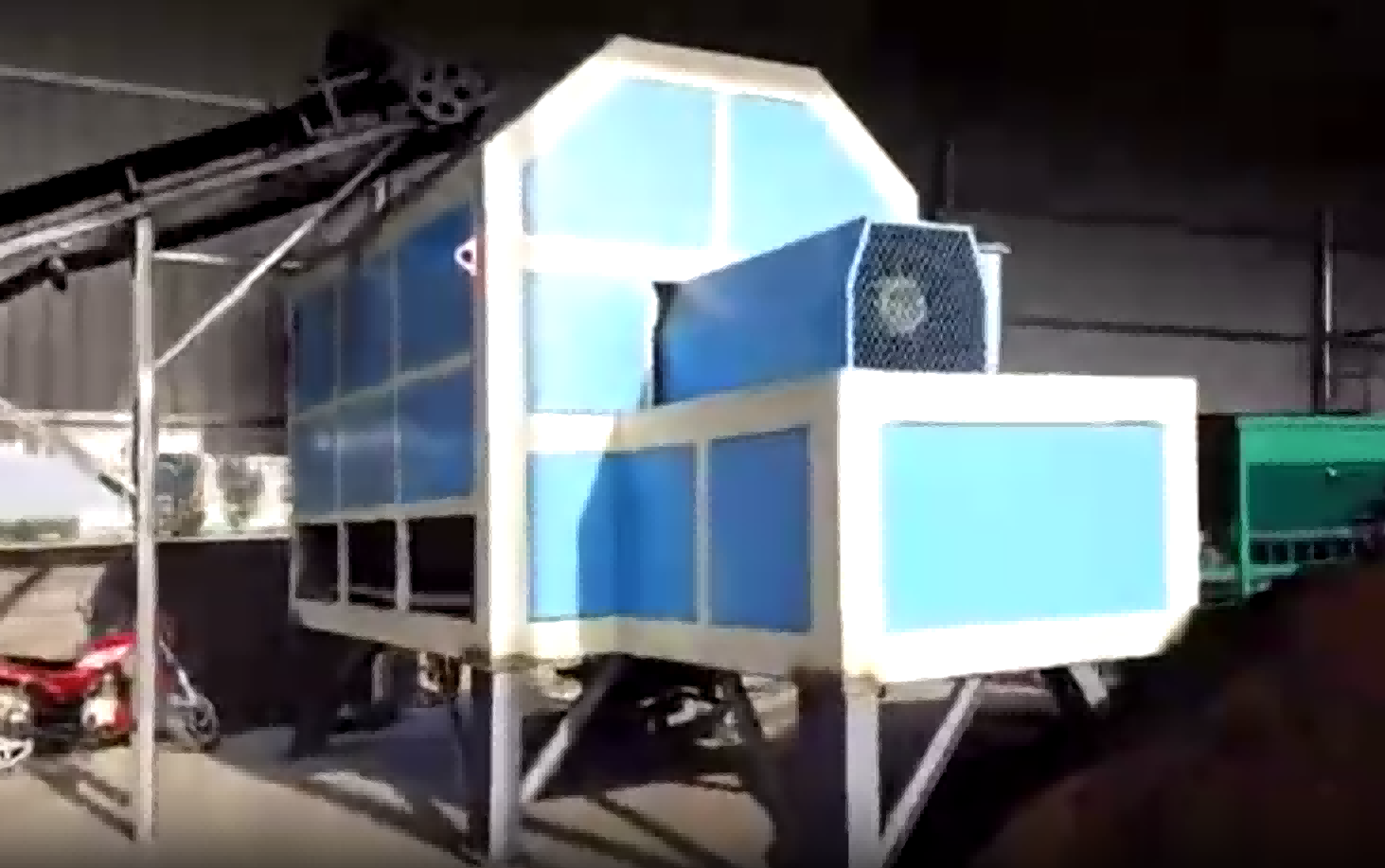

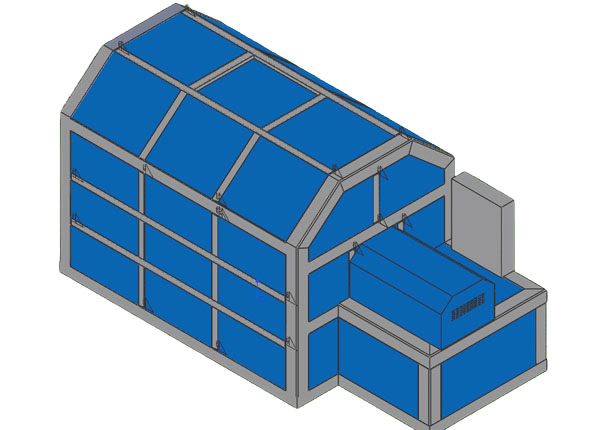

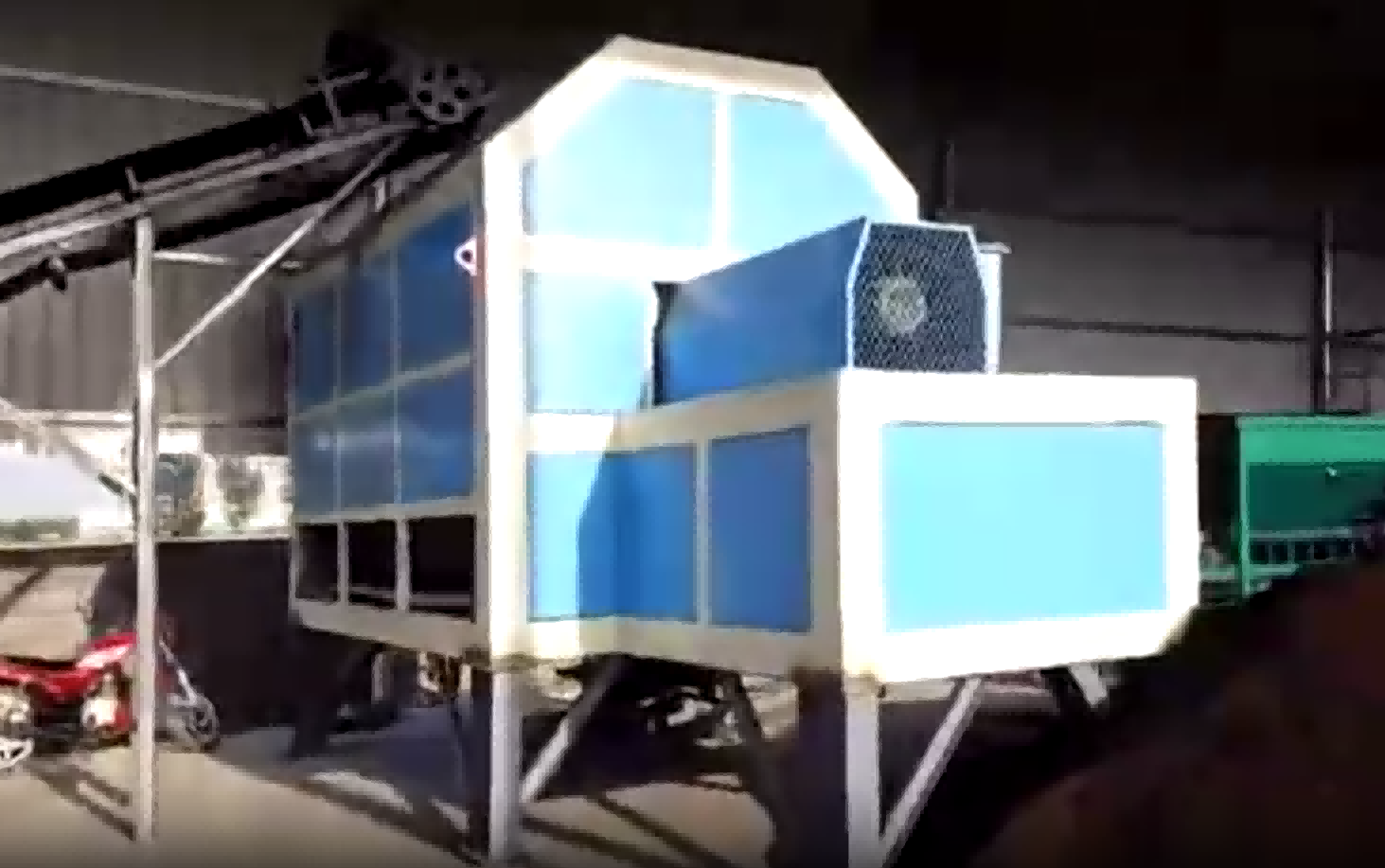

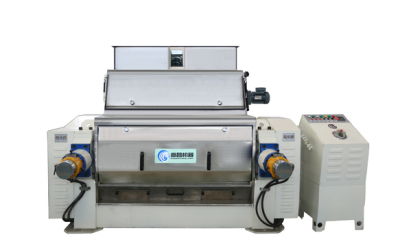

Horizontal fermentation tank

1. Suitable for a variety of materials: The tank body of the horizontal fermentation tank is placed horizontally, and the internal space is relatively open. It has good adaptability for solid fermentation products, soft solid fermentation products, and liquid fermentation products.

2. Avoid material entanglement: The horizontal fermentation tank achieves material stirring by rotating the tank body, without the need for a stirring paddle, thus completely avoiding the problem of fermentation products entangled with the stirring paddle.

3. Full mixing and stirring: The rotation of the tank body can fully stir and mix the materials in the tank, so that the fermentation raw materials are more evenly contacted with microorganisms, oxygen, etc., which is conducive to improving the fermentation efficiency and product consistency.

4. Enhanced mass transfer and heat transfer effects: The horizontal tank body design is conducive to the transfer of heat and materials. During the fermentation process, whether it is heating or cooling, temperature control can be achieved faster and more evenly.

3. Lower installation height: The installation height of the horizontal fermentation tank is low, and during the installation, commissioning and daily operation of the equipment, it does not require excessively high plant space and complex lifting equipment.

4. Convenient material entry and exit: Usually, a larger inlet and outlet are set on the tank body to facilitate the entry and removal of fermentation products.

5. Easy to clean and disinfect: Its internal structure is relatively simple, and the tank can be flushed with water or cleaning fluid to a certain extent when it rotates, which is more conducive to thorough cleaning and disinfection.

6. Strong scalability: The volume of the horizontal fermentation tank can be designed and expanded to a large extent according to production needs.

The horizontal fermentation tank is mainly used for high-temperature aerobic fermentation of wastes such as livestock and poultry manure, kitchen waste, and domestic sludge. It uses the activity of microorganisms to biologically decompose the organic matter in the waste, making it harmless, stabilized, reduced, and resource-based. It is an integrated sludge treatment equipment.

The products obtained after high temperature aerobic fermentation can be used for soil improvement, landscaping, landfill covering soil, etc. The products obtained after high temperature aerobic fermentation can be used for soil improvement, landscaping, landfill covering soil, etc.

High-temperature aerobic fermentation uses high-temperature biological bacteria technology, with low energy consumption and low operating costs; the equipment occupies a small area and has a high degree of automation, so the fermentation process can be completed by one person; biological deodorization equipment is used to achieve gas emission standards without generating secondary pollution; the main body is insulated and auxiliary heating ensures normal operation of the equipment in a low-temperature environment.

Waste (livestock and poultry manure, kitchen waste, domestic sludge, etc.), biomass (straw and sawdust, etc.) and return materials are mixed evenly in a certain proportion, and the moisture content reaches the design requirement of 60-65%. Then they enter the three-dimensional aerobic system, and the materials are fully aerobic fermented and decomposed by adjusting the moisture, oxygen content and temperature of the raw materials.

The temperature of the organic fertilizer fermentation tank is controlled between 55 and 60°C through ventilation, oxygenation, stirring, etc., reaching the temperature for material fermentation treatment. At this temperature, a large number of pathogens and parasites in the pile can be killed. At the same time, the deodorization system is used to remove the biological odor of the emitted gas to achieve the purpose of harmless treatment.

Application areas:

Food and beverage industry: used for the fermentation production of food and beverages such as beer, wine, yogurt, soy sauce, vinegar, etc., which helps to improve the quality and taste of the products.

Pharmaceutical industry: suitable for the fermentation production of antibiotics, vaccines, biologically active substances and other drugs, meeting the strict requirements of the pharmaceutical industry for production environment and equipment.

Environmental protection field: can be used to treat organic waste, such as fermenting agricultural waste, kitchen waste, etc. into organic fertilizer or bioenergy.

Biochemical industry: plays an important role in the production of biochemical products such as alcohol, bioethanol, biodiesel, etc., improves fermentation efficiency and product conversion rate, and reduces production costs.