Highly efficient Screening stone remover

1. Large processing capacity: It can process a large amount of materials per unit time, quickly screen out stones from the materials, and greatly improve production efficiency.

2. Fast screening: The use of advanced screening technology and reasonable structural design enables the materials to be quickly layered and screened on the screen surface.

3. High screening accuracy: It has a precise screening function and can accurately separate stones from other materials according to the set parameters such as stone size.

4. Multi-stage screening: Some high-efficiency stone screening machines can be equipped with multi-layer screens or use multi-stage screening processes to screen and grade materials multiple times, making the removal of stones more thorough.

5. Smooth operation: Through the optimized mechanical transmission system and balanced design, the stone screening machine generates less vibration and noise during operation, and the operating state is more stable.

6. Automatic control: It is usually equipped with an advanced automatic control system, which can realize remote operation, monitoring and fault diagnosis of the equipment.

High-efficiency stone screening machine is a kind of mechanical equipment specially used for fast and accurate screening of stones from various materials. It is widely used in many fields such as construction, mining, agriculture, environmental protection, etc. It plays a vital role in the material processing process and effectively improves the material quality and subsequent processing efficiency.

Brand of screening stone removal machine: Bremetz

Power supply voltage of screening stone remover: 380 (V)

Power of screening stone removal machine: 1.1kw

Product packaging of screening stone removal machine: simple

Size of screening stone removal machine: 1400*1680*2160 (mm)

Weight of screening stone removal machine: 630 (kg)

Screening stone removal machine processing capacity: 1000-15000 (kg/h)

The use of precise screening technology and reasonable structural design enables the materials to be quickly layered and screened on the screen surface. The stones can be accurately separated according to the particle size difference between the stones and the materials, ensuring that the screened materials meet the specific particle size requirements and improving product quality. This high-precision screening is particularly important for some industries that have extremely high requirements for material purity, such as the production of high-end building materials or the preparation of fine chemical raw materials.

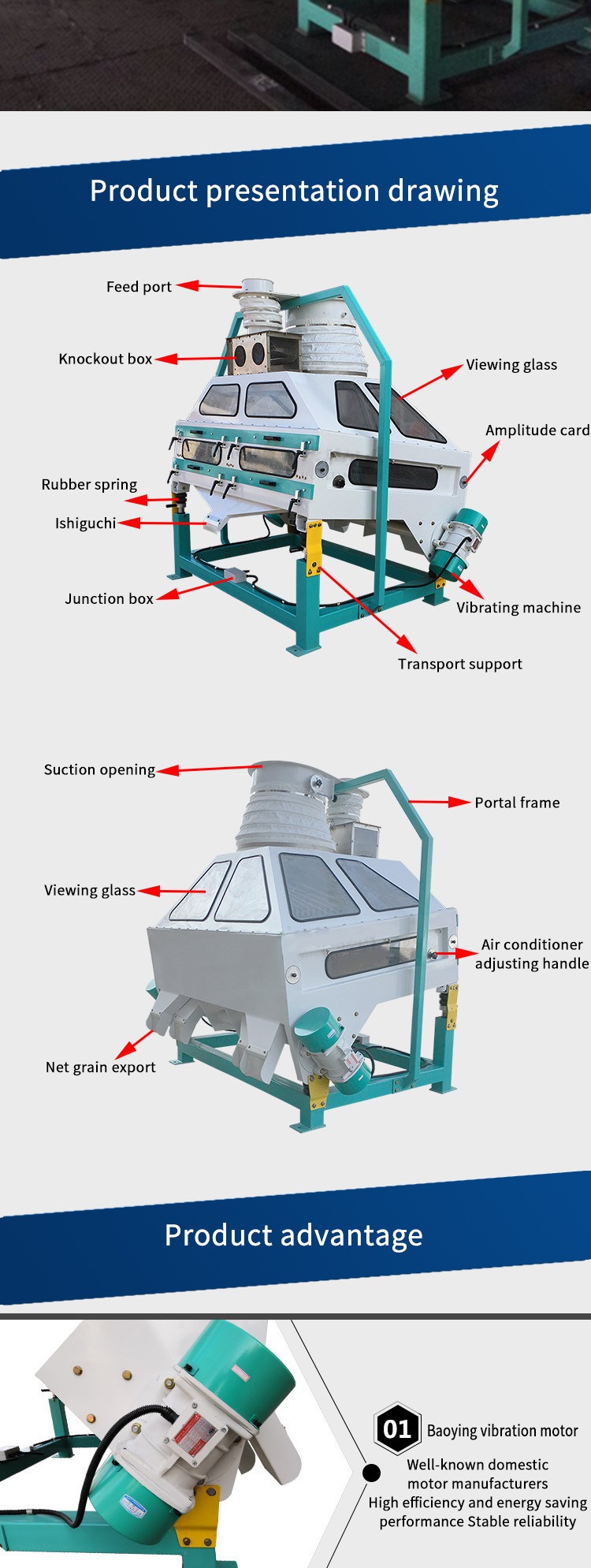

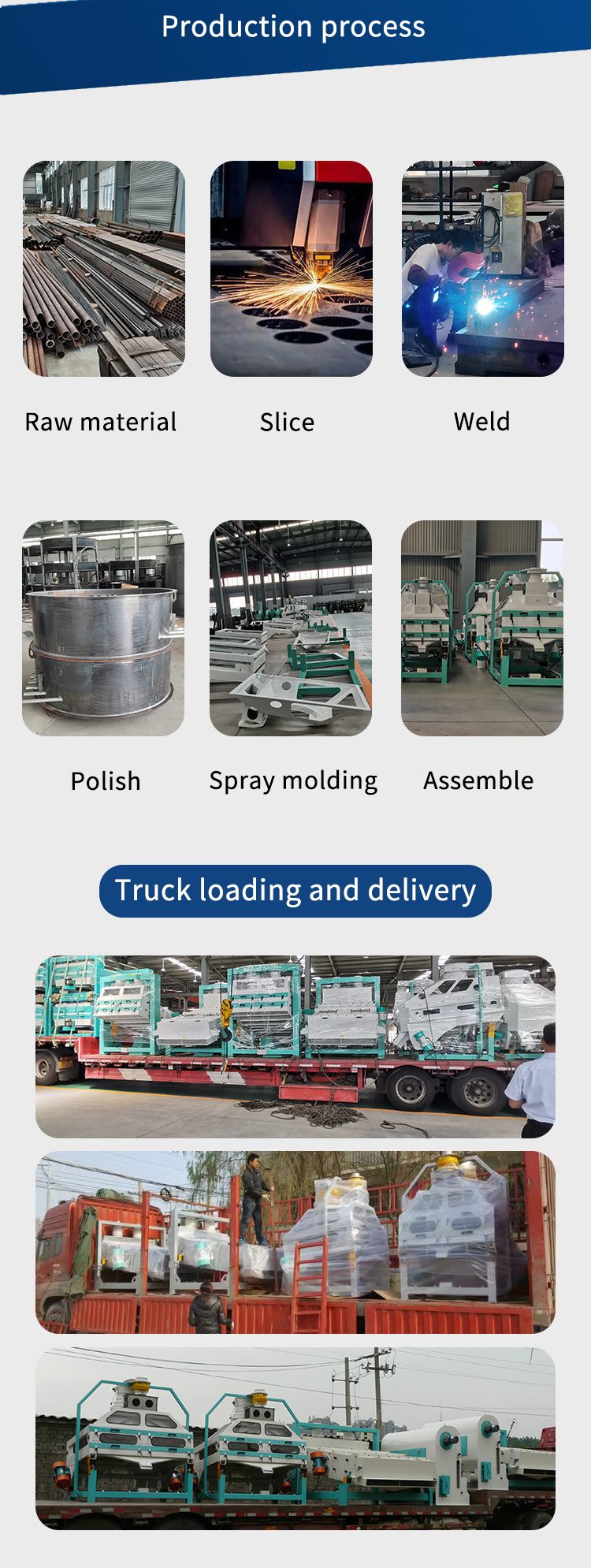

The overall structure of the equipment is reasonably designed, and key components are made of high-strength materials and undergo special treatment and reinforcement. For example, the screen body has exquisite welding technology and can withstand large material impact and vibration, ensuring that the equipment will not suffer from deformation, cracking and other problems during long-term operation, significantly extending the service life of the equipment and reducing the need for equipment updates. cost.

Through the optimized mechanical transmission system and balanced design, the stone screener generates less vibration and noise during operation. The stable operation state not only reduces the interference and health hazards to the operators, but also helps to improve the consistency and reliability of the screening effect, while reducing the failure rate and maintenance costs of the equipment, and reducing the production delays caused by equipment downtime for maintenance.

It can adapt to various types of materials, including ore, coal, sand, grain, construction waste, etc. Whether it is dry or wet materials, whether it is granular or block materials, it can effectively screen stones. This powerful versatility makes the efficient stone screener have a wide range of applications in many industries and meet the diverse needs of different users.

Wide particle size range processing: It can effectively screen and separate stones and materials of different particle size ranges. From small particles of stone to larger stones, efficient screening can be achieved with the corresponding stone screener model or by adjusting the appropriate parameters. This feature provides users with greater flexibility without having to purchase multiple specialized screening equipment for materials of different particle sizes.