Steam Corn Tablet Solution

Steam corn pressure background

Grain steam-pressure tablets were first tested (in the early 1960s) on growing and fattening cattle and proved to improve their feeding efficiency, which was related to the increase of starch digestibility and the increase of propionic acid proportion in the rumen and the decrease of acetic acid proportion.

Because of the role of acetate in milk fat synthesis, which in turn plays an important role in milk pricing, grain steam-compression technology has not been widely used in dairy farming. After the 1990s, when milk protein content became a more important factor in milk pricing than milk fat content, grain steam-compression technology was widely adopted in the dairy industry around the world.

In 2005, Professor Meng Qingxiang of China Agricultural University and Mr. Yang Haizeng, chairman of Hebei Kite Group, introduced a full set of steam corn compression technology from the United States.

In 2018, Bremetz provided Kaite Group with automatic steam corn press with a daily processing capacity of 350 tons, and since then Bremetz has entered the field of steam corn press, becoming a pioneer in China's corn press industry.

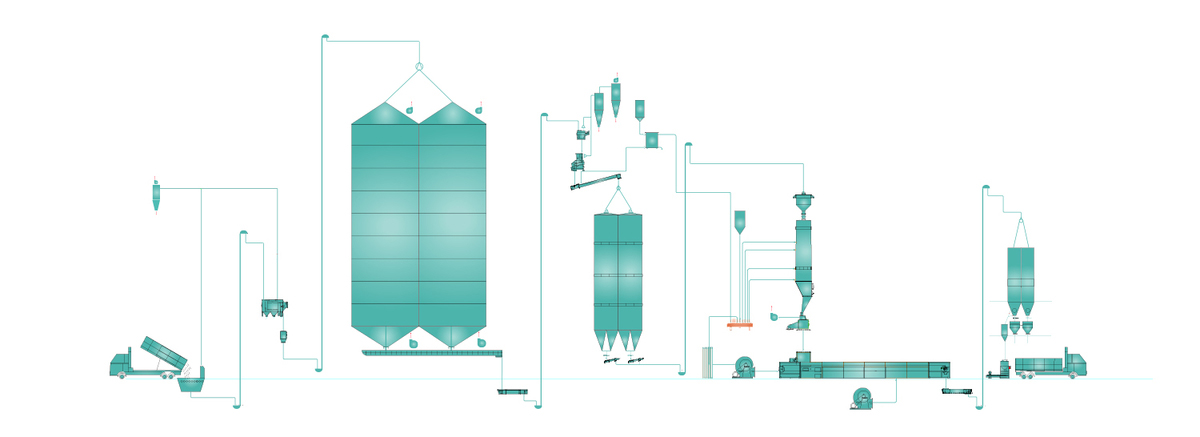

Steam corn tablet process introduction:

Inlet → primary cleaning screen → Steel plate bin → Cleaning → Soaking bin → tempering tower (cooking) → sheet pressing → drying box → finished product bin → packing scale/bulk

Steam corn tablet process introduction:

Steam corn flakes are matured and softened by steam heat treatment, and then processed into 1.5mm-2mm flake shape by corn flakes. The principle of steam corn compression is actually a gelation process, which is to destroy the hydrogen bond of tightly bound corn starch through gelation, so as to improve the digestibility of corn starch to animals.

The chemical structure of protein in corn was changed during steam-compressed corn, which was beneficial to rumen absorption of starch. The main factors that promote the gelation process and improve the overall digestibility of corn by steam compression are water, energy, treatment time and mechanical action. The role of water is to expand and soften, and heating can make electrons move, destroy hydrogen bonds, and promote the gelation reaction. Sufficient steam tempering treatment time is the guarantee of adequate gelation process. The function of corn flake roll is a process of roll forming and reaching the specified flake density.

Finished product index: gelatinization degree: 65-75% adjustable volume weight: 380-400 Finished moisture: 13-16% adjustable

Equipment energy consumption: 10 tons per hour (200 tons per day) corn press workshop, total power of about 260kw Steam demand: 5-6 tons/saturated steam/pressure 0.8Mps

Infiltration system: Material optional carbon steel or stainless steel infiltration is conducive to improving the degree of gelatinization and reducing the modulation time for pasture own use can not be dried after adding water can use scraper or separator soaking time 6-24 hours to improve moisture 2-4%. According to the site requirements, 4-12 soaking silos can be designed, with a total volume of 320m³, and a total of 224 tons of soaked corn can be stored based on the corn bulk weight of 700

Advantages of steam corn tablet for animal consumption:

Steam corn flakes are mainly used in the feeding of ruminants, such as beef cattle, dairy cows, sheep, horse feed, and will be used in chicken feed and pig feed in the future, which has been widely used in Europe. At this stage, domestic or small-scale farming, while foreign countries are already large farms, the cost is lower than that of China, and Chinese livestock enterprises want to make profits, can not sacrifice food safety, then you need to start from the cost of feeding. If a large-scale ranch uses 10,000 tons of crushed corn a year, the use of corn compacts can save at least 15% of corn use, and the high gelatinization of corn compacts can increase the absorption rate of feeding livestock, thereby reducing the use of crushed corn that is not digested and absorbed, while reducing the residue from animal feces, so that all corn is digested and absorbed.

Advantage 1 Saving raw grain: estimated to save 1,500 tons of corn per year, 1800 yuan/ton of corn price, can help the ranch save nearly 3 million yuan a year;

Advantage 2 Improved digestion and absorption rate: from the original direct consumption of unmatured corn absorption rate of 60% to 98% consumption of matured corn tablet;

Advantage 3: Reduce the production cost: the production cost of expanded feed is 420 yuan (7×24 hours) and the production cost of corn flakes is 115 yuan (7×24 hours);

Advantage 4: Improving animal palatability: changing from eating raw corn to eating aged corn, greatly improving animal palatability;

On-site equipment display: