Powered Roller Conveyor

1. Powered roller conveyors can achieve high conveying speeds, usually 10 to 30 meters per minute or even higher. Effectively reduce production cycles or cargo delivery time.

2. Multiple powered rollers are arranged in sequence to form a conveying plane, and the uniform rotation of the rollers is used to achieve smooth advancement of items.

3. Whether it is a small component, a large box, or even an irregularly shaped object, as long as its bottom can contact the roller and obtain sufficient friction, it can be smoothly conveyed on the powered roller conveyor.

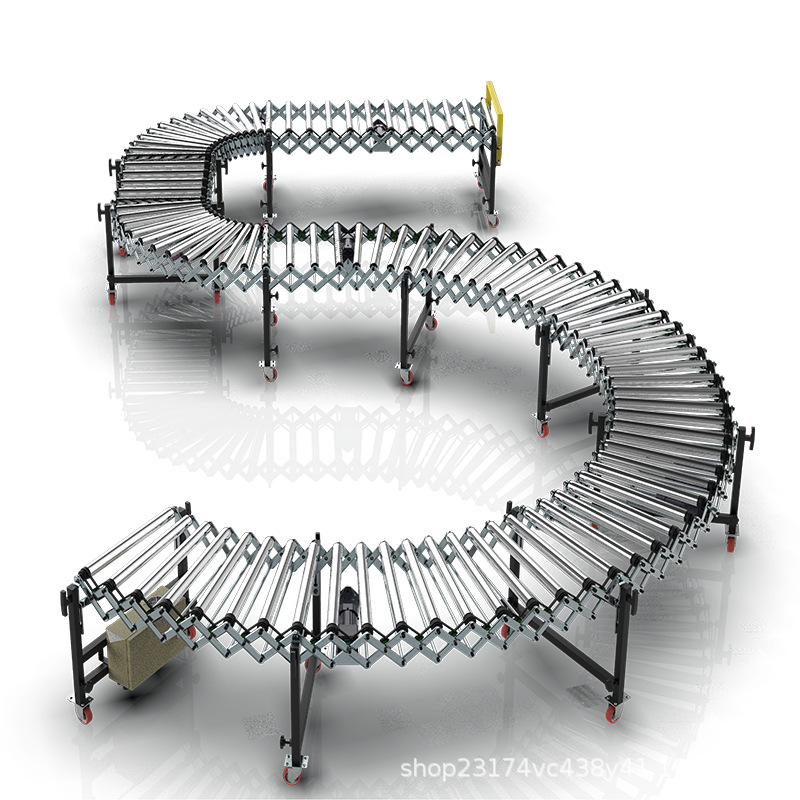

4. The structure of the powered roller conveyor is relatively simple, and it can be flexibly designed according to the actual site space and production process requirements.

5. It is easy to add new roller segments, change the conveying direction, or add branch lines on the basis of the original conveyor system.

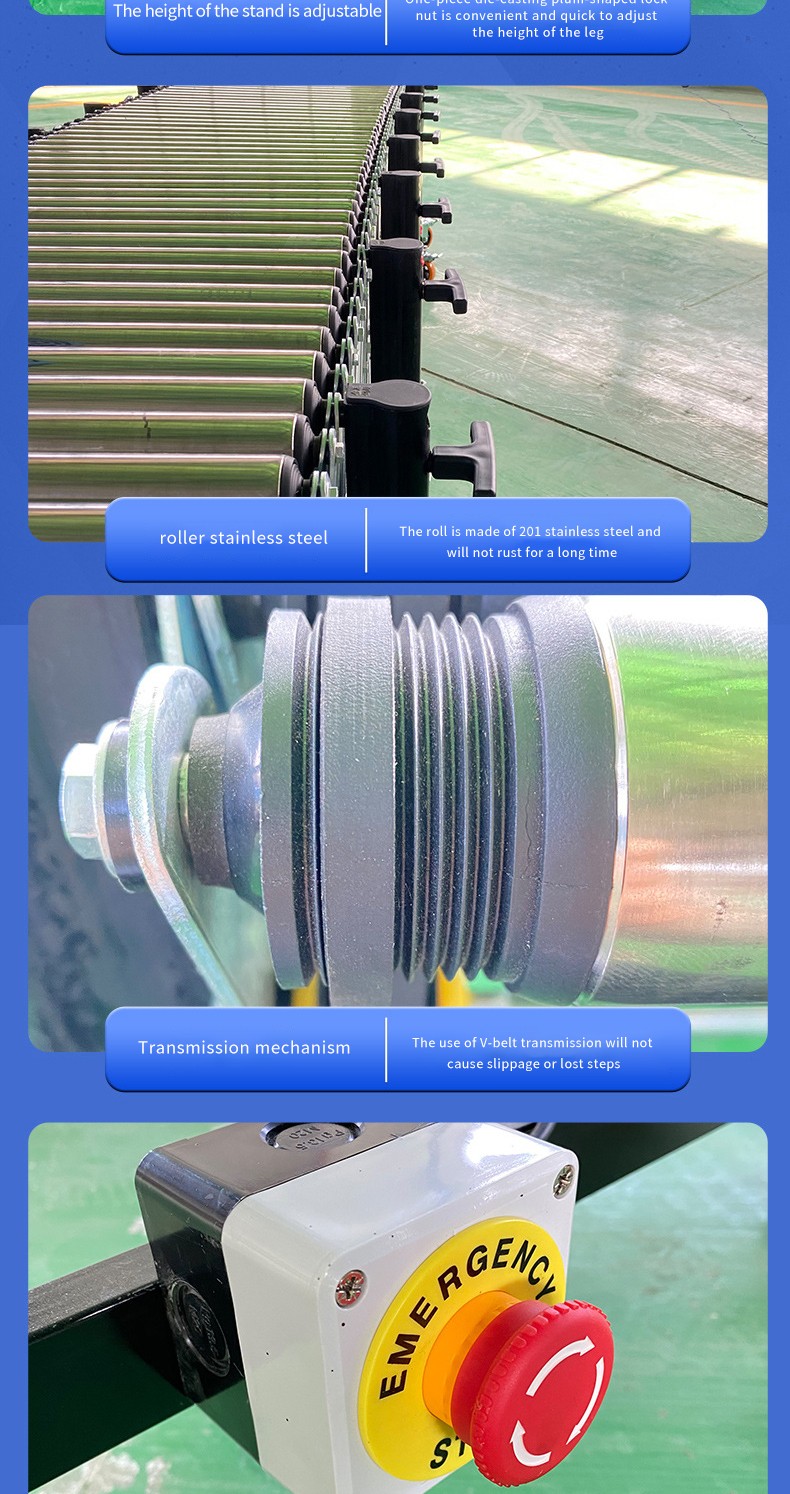

6. The use of high-quality materials and advanced manufacturing processes ensures the high reliability and long service life of the equipment.

Powered roller conveyor is a kind of material conveying equipment widely used in industrial production, logistics warehousing and other fields. It drives the roller to rotate through the motor and uses the friction between the roller and the conveyed objects to achieve smooth transportation of the objects.

It can achieve a relatively high conveying speed, generally up to 10 to 30 meters per minute or even higher, and the running posture of the items during the conveying process is stable, reducing the risk of damage to the items due to bumps and collisions. It is suitable for large-scale, high-efficiency production and logistics operations.

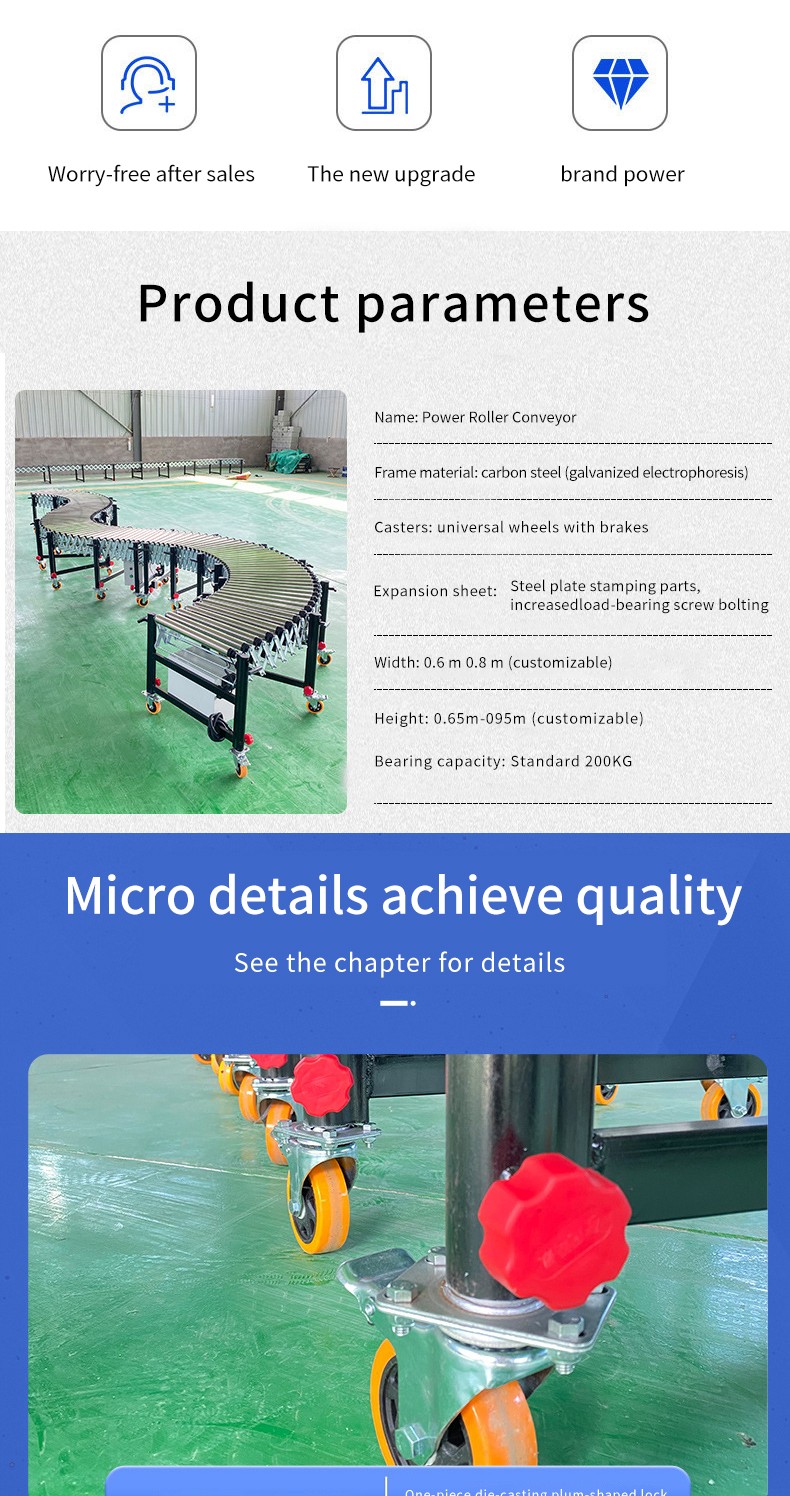

Name: Power Roller Conveyor

Frame material: carbon steel (galvanized electrophoresis)

Casters: universal wheels with brakes

Expansion sheet: Steel plate stamping parts, increasedload-bearing screw bolting

Width: 0.6 m 0.8 m (customizable)

Height: 0.65m-095m (customizable)

Bearing capacity: Standard 200KG

It can transport items of various shapes, sizes and weights, from tiny parts to large boxes and pallets. It can play an excellent role in the transportation of raw materials, semi-finished products and finished products in the manufacturing industry, as well as in the sorting, storage and distribution of goods in the logistics and warehousing industry.

The structure is simple and can be easily designed into various shapes and layouts, such as straight, curved, branched, converging, etc. It can be customized according to the actual needs of the site space and production process. In addition, when it is necessary to expand the production scale or adjust the logistics line, it can be easily expanded and modified, adding new roller sections or changing the conveying direction.

The structure of the main components is relatively simple, and the maintenance work mainly focuses on the cleaning and lubrication of the drum and the inspection and maintenance of the transmission parts and motors. It is easy to operate and has low maintenance costs. At the same time, the use of high-quality materials and advanced manufacturing technology has high reliability of the equipment.

The motor drive method is relatively energy-saving, especially after adopting energy-saving motors and intelligent control technology, it can reasonably adjust the power output according to the actual transportation task and reduce energy consumption. In addition, the noise generated during its operation is small, and generally no dust, leakage or other environmental pollution problems will be generated, which meets environmental protection requirements.