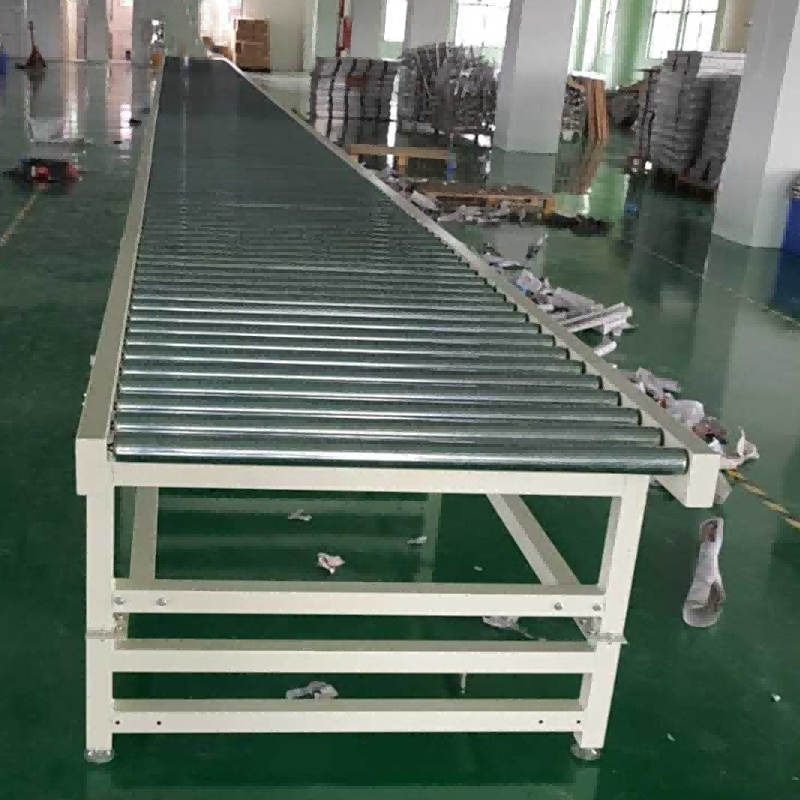

High speed roller conveyor

1. High-speed operation: With a high conveying speed, it can achieve a conveying speed of tens of meters or even hundreds of meters per minute according to different configurations and requirements, and can quickly transport a large amount of materials in a short time.

2. Stable and continuous operation: With high-quality mechanical structure and power system, it can still maintain good stability under high-speed operation to ensure the continuity of material transportation.

3. Adapt to heavy object transportation: The structural characteristics of the roller conveyor itself determine that it has a strong bearing capacity, and its roller is generally made of sturdy and durable metal materials.

4. Dispersed bearing pressure: Multiple rollers share the weight of the material, which can disperse the pressure more evenly than some other conveying methods.

5. Flexible layout: It can be flexibly designed and installed according to the spatial layout, process flow and material conveying path requirements of the actual site.

6. Good material compatibility: It is suitable for conveying materials of various shapes, sizes and materials. Whether it is regular-shaped items or some irregular-shaped goods, they can be placed on the rollers for transportation.

High speed roller conveyor is a kind of mechanical equipment that uses rollers as bearing and conveying components and relies on power drive to achieve high-speed and efficient material transportation. It plays an extremely important role in many fields such as modern industrial production, logistics and warehousing. With its unique structure and excellent performance, it can meet the needs of various enterprises for fast, stable and accurate material transportation.

Eight core strengths:

Preferred material;Lifetime maintenance;

Easy installation;Professional team;

Easy maintenance;Meticulous workmanship;

Strong and durable;Meet the demand.

Depending on the structural design and configuration, the load capacity varies greatly, ranging from tens of kilograms to several tons. Small high-speed roller conveyors can carry lighter materials such as electronic products and small packaged foods, and their load capacity may be from tens of kilograms to hundreds of kilograms; while large conveyors used for industrial production or logistics warehousing can carry heavy materials such as pallet cargo and mechanical equipment parts, and their load capacity can reach several tons, which can meet the transportation needs of materials of different weight levels.

The bracket and frame are usually welded or assembled from steel sections, with sufficient strength and rigidity to stably support the roller and the weight of the material carried, ensuring that the entire conveyor will not deform or shake during high-speed operation, providing a solid foundation for the smooth transportation of materials.

Some brackets have height and angle adjustment functions, which facilitates the flexible adjustment of the installation position and posture of the conveyor according to different site conditions and docking requirements with other equipment, enhancing the adaptability and versatility of the equipment.

A variety of transmission methods are used to transmit power, the most common of which are chain transmission, belt transmission and gear transmission. Chain transmission has the characteristics of large load-bearing capacity and high transmission efficiency, and is suitable for heavy-load and high-speed conveying occasions; belt transmission is relatively stable, low-noise, and can buffer and reduce shock to a certain extent, and is often used in places with high requirements for running stability; gear transmission has high precision and strong reliability, and can achieve accurate speed and power transmission.

It has automatic control logic and can realize precise control of the conveyor, such as automatically adjusting the conveying speed according to the preset program, controlling the start and stop of the roller according to the material sensing signal, etc. At the same time, it also has fault diagnosis and alarm prompt functions. When abnormal situations such as motor overload, roller jamming, conveyor belt deviation (if there is a conveyor belt) occur, the fault information can be displayed on the operation interface in time, and an audible and visual alarm will be issued, which is convenient for maintenance personnel to quickly locate and solve the problem and ensure the stable operation of the equipment.

A professional technical team provides on-site installation services, and accurately installs the equipment according to the actual situation of the customer's site and the equipment requirements. After the installation is completed, the equipment is fully debugged, including checking the installation firmness of each component, the rotation flexibility of the roller, the power transmission of the drive system, and the parameter setting of the control system, etc., to ensure the normal operation of various functions of the equipment and achieve the best conveying effect.

Provide users with operation training and maintenance training, and guide operators on-site to become familiar with the equipment's operation interface, parameter settings, daily maintenance points, and methods for handling common faults, so that operators can operate and maintain the equipment correctly and skillfully, reduce equipment failures caused by misoperation, and ensure the long-term stable operation of the equipment.

We have established a complete after-sales maintenance network and equipped it with professional maintenance personnel. After receiving the user's fault report, we can respond quickly and rush to the site for maintenance in time. The maintenance personnel have rich maintenance experience and professional knowledge, can accurately diagnose the cause of equipment failure, and take effective maintenance measures to repair it.