Power roller telescopic line

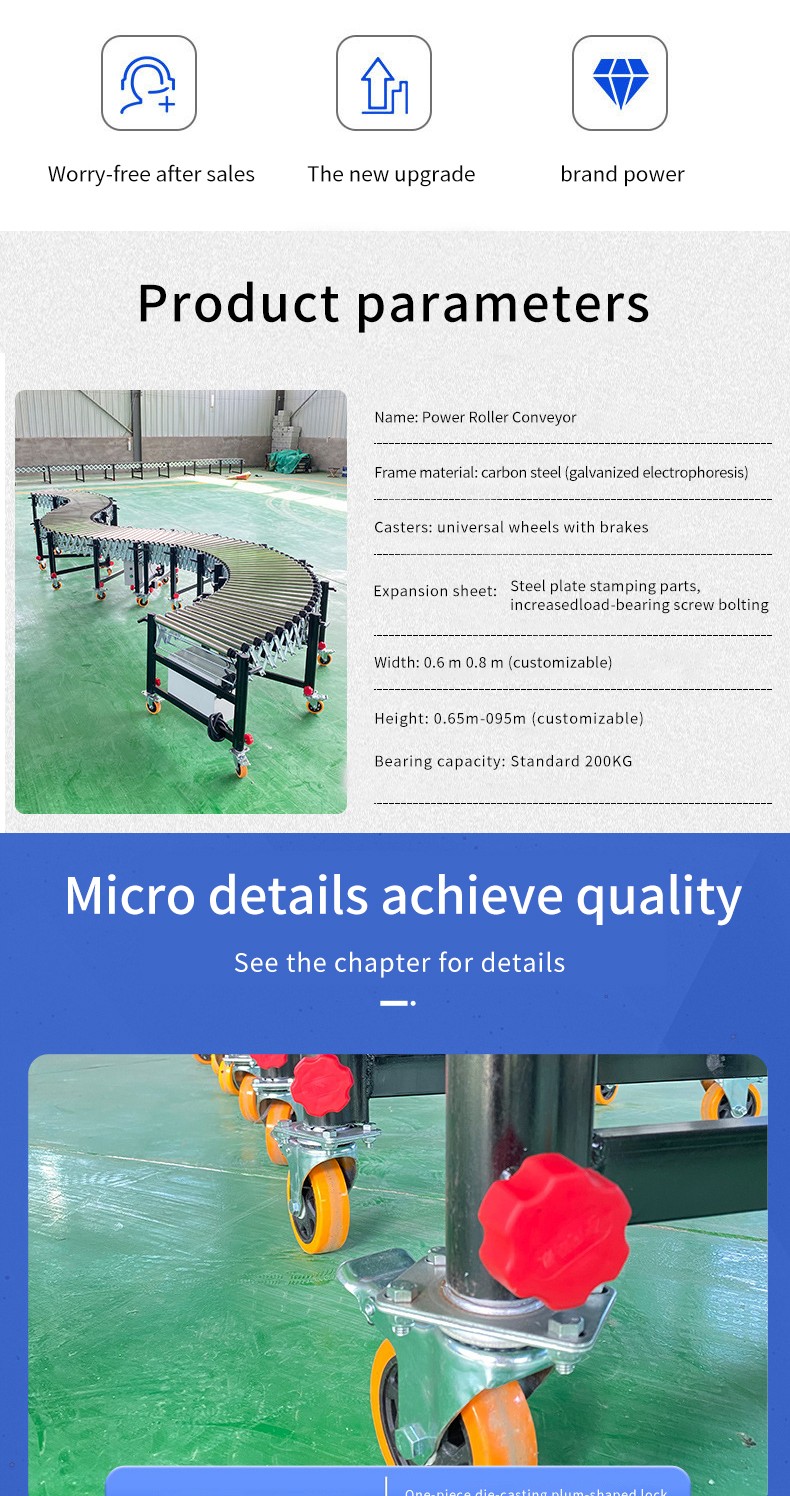

1. High flexibility: The length of the conveyor line can be freely adjusted according to actual operation needs. It can be shortened in areas with limited space to save space, and can be extended when long-distance transportation is required.

2. Changeable direction: The conveying direction can be flexibly changed, and even 180 or 360 degrees can be turned, which is very suitable for occasions where the direction of cargo transportation needs to be changed.

3. Strong applicability: It can not only convey various types of common goods such as pallets, bags, bagged materials, cartons, etc., but also can convey some irregularly shaped goods well.

4. Adapt to various terrains: Whether on flat ground or on a certain slope or uneven ground, the power roller telescopic line can operate well, and the height of the legs can be adjusted according to the actual terrain to ensure the stability and smoothness of the transportation.

5. High work efficiency: The power-driven roller can move the goods quickly, which greatly improves the conveying speed of the goods compared to manual handling or other non-powered conveying methods, and helps to improve the efficiency of the entire production or logistics operation.

6. Strong load-bearing capacity: After special design and manufacturing, the power roller telescopic line has a strong load-bearing capacity and can withstand heavier goods, ensuring the stability and safety of the equipment during the transportation process.

Organic fertilizer bucket elevator is a highly efficient equipment specially used for vertical lifting of organic fertilizer. It plays a vital role in the production, processing and storage of organic fertilizer. It can stably and quickly lift organic fertilizer from a low place to a high place, ensuring the smooth progress of the entire production process. The equipment realizes reliable transportation of organic fertilizer through a series of hoppers in a vertical cycle, and is widely used in various organic fertilizer production enterprises and related processing facilities.

Name: Power Roller Conveyor

Frame material: carbon steel (galvanized electrophoresis)

Casters: universal wheels with brakes

Expansion sheet: Steel plate stamping parts, increasedload-bearing screw bolting

Width: 0.6 m 0.8 m (customizable)

Height: 0.65m-095m (customizable)

Bearing capacity: Standard 200KG

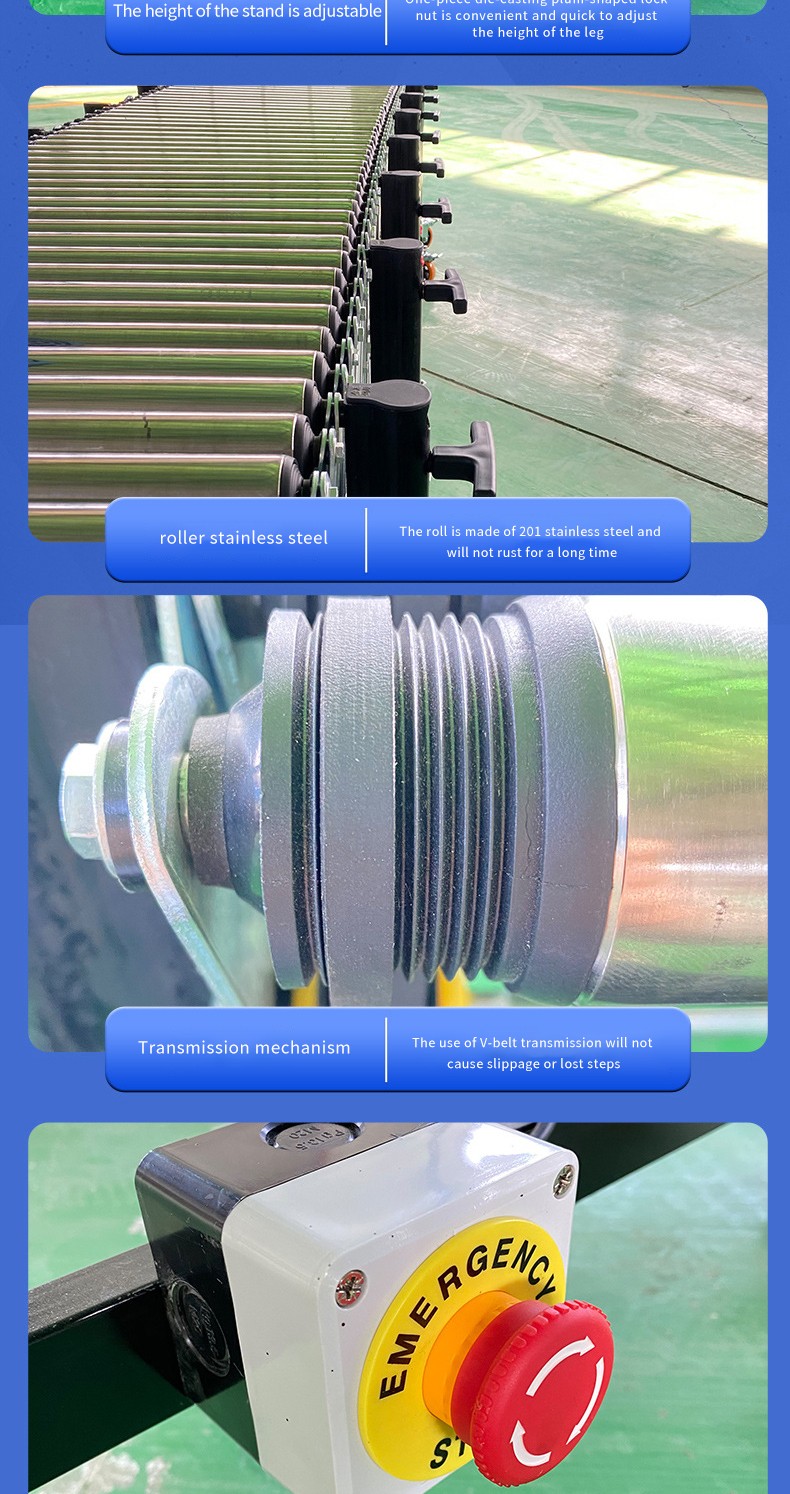

The height of the stand is adjustable,nut is convenient and quick to adjust the height of the leg.

The roll is made of 201 stainless steel and will not rust for a long time.

Transmission mechanism,The use of V-belt transmission will not cause slippage or lost steps.

Safety switch,The tail is equipped with an emergency stop switch, and the receiving personnel can control the start and stop of the conveyor

Control circuit,The standard configuration of Changsha Beishide inverter adopts module control, Chint electronic components.

The organic fertilizer bucket elevator can quickly and stably lift organic fertilizer vertically to a higher position. Its lifting speed can be adjusted within a certain range according to actual needs to meet the requirements of different production scales and organic fertilizer flow rates. In large-scale organic fertilizer production, such as the production lines of large-scale organic fertilizer factories, it can significantly improve production efficiency, reduce organic fertilizer transportation time, and ensure the efficient operation of the production process.

The structural design and working principle of the organic fertilizer bucket elevator ensure its stability during long-term operation. High-quality transmission components, firm hopper connection and stable casing structure enable the equipment to withstand the continuous loading of organic fertilizer and various stresses during operation. At the same time, a reasonable control system and overload protection mechanism can effectively prevent the equipment from being damaged due to abnormal conditions, ensuring the reliability of the equipment and reducing the time and frequency of equipment downtime for maintenance.

Application areas: Organic fertilizer production enterprises, used to lift various raw materials in the process of organic fertilizer production. Lift them from the raw material collection area to the pretreatment workshop for crushing, mixing and other operations.

Agricultural planting bases, in some large agricultural planting bases. Organic fertilizer bucket elevators can lift organic fertilizers from the composting field to the transport vehicle for fertilization in the field.

Organic fertilizer storage and logistics center, used for storage and transportation of organic fertilizers in the warehouse. Lift the organic fertilizer entering the warehouse from the ground to shelves or storage bins at different heights to achieve efficient storage management.

We have a professional after-sales maintenance team that can respond promptly to user fault reports. Our maintenance personnel have rich maintenance experience and professional knowledge and can quickly diagnose and solve equipment problems.