Organic fertilizer bucket elevator

1. Good conveying sealing: Material conveying in a closed pipe or tank body can prevent leakage and dust for materials such as organic fertilizer that may produce odor or dust, and reduce pollution to the environment.

2. Multiple conveying directions can be achieved: It can be conveyed horizontally, tilted within a certain angle range, and even complex conveying paths with multiple bends and turns in the middle can be achieved, which can adapt to different sites and process requirements.

3. Strong adaptability to materials: It can convey organic fertilizers in various forms, whether it is granular, powdery or small pieces, it can be conveyed stably.

4. Simple structure and convenient operation and maintenance: Its structure is relatively simple, mainly composed of a screw shaft, a housing, a drive device, etc., with fewer parts and easy installation and disassembly. The daily maintenance cost is low.

5. Large conveying volume: It has a large conveying capacity and can meet the material conveying needs of large-scale organic fertilizer production. The bandwidth and belt speed can be selected and adjusted according to actual conditions.

6. Smooth operation: The speed of the conveyor belt is relatively stable during operation, and the distribution of materials on the conveyor belt is also relatively uniform, which is conducive to protecting the particle integrity of the organic fertilizer and reducing the breakage and loss of materials.

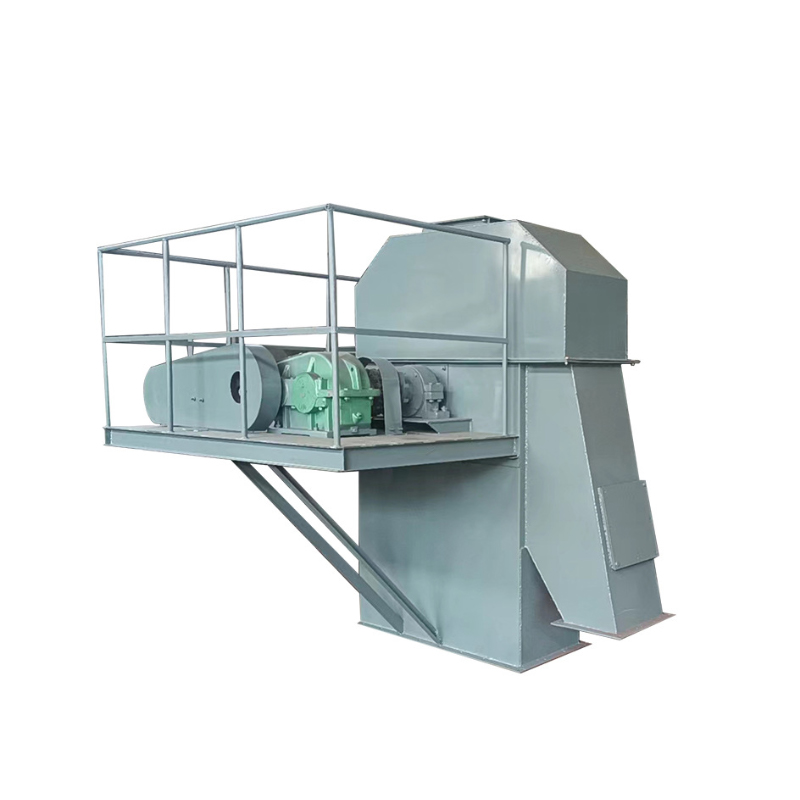

Organic fertilizer bucket elevator is a highly efficient equipment specially used for vertical lifting of organic fertilizer. It plays a vital role in the production, processing and storage of organic fertilizer. It can stably and quickly lift organic fertilizer from a low place to a high place, ensuring the smooth progress of the entire production process. The equipment realizes reliable transportation of organic fertilizer through a series of hoppers in a vertical cycle, and is widely used in various organic fertilizer production enterprises and related processing facilities.

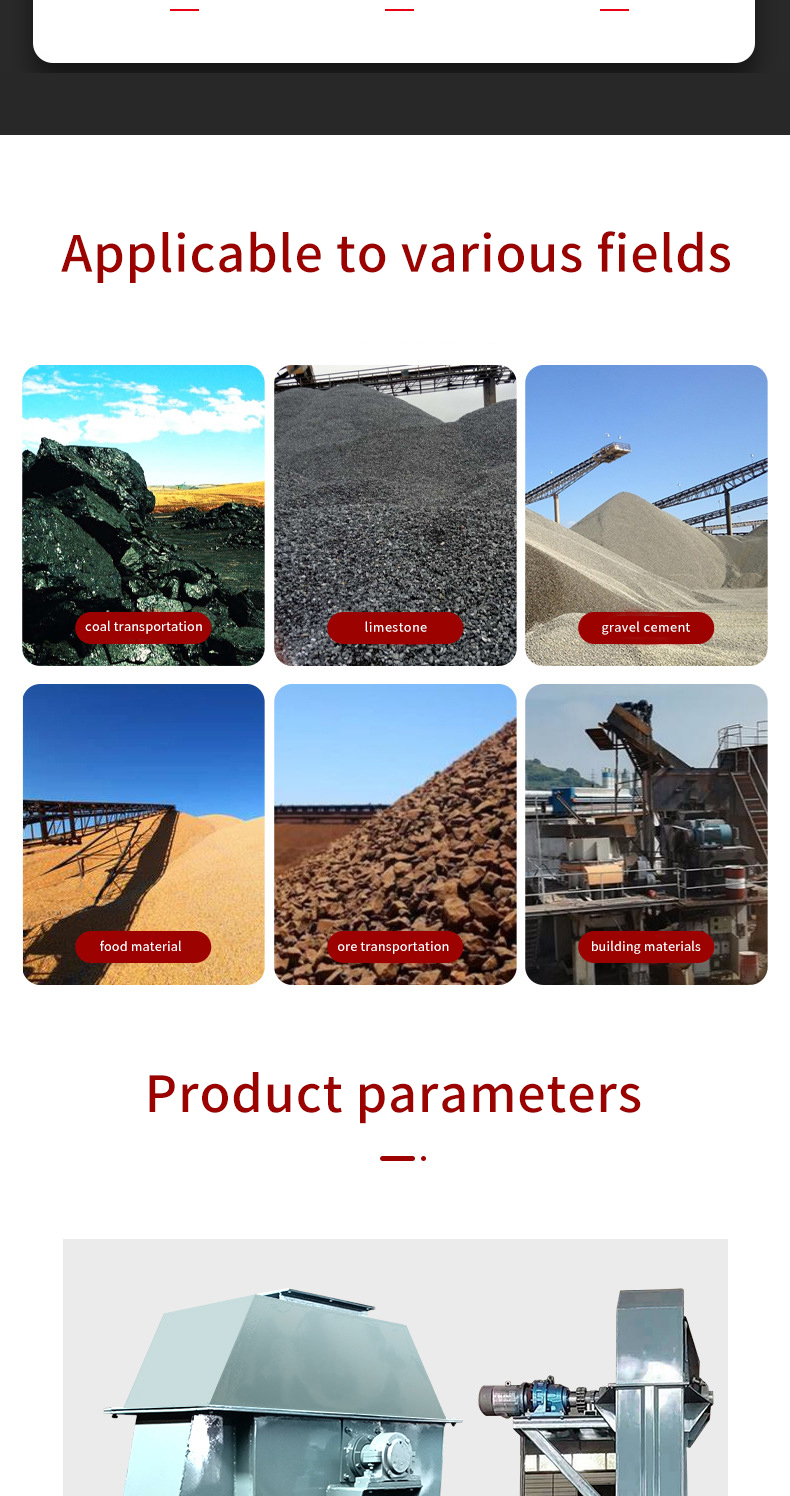

Applicable to various fields:coal transportation,limestone,gravel cement,food material,ore transportation,building materials.

In the process of organic fertilizer production, it is used to lift various raw materials, such as livestock and poultry manure, crop straw, peat soil and other materials that have been fermented. It is lifted from the raw material collection area to the pre-treatment workshop for crushing, mixing and other operations. At the same time, during the production process, organic fertilizer products at different stages are transported from one process to the next to ensure the continuity of production.

product name:Bucket elevator

Manufacturer:bremetz

Material:NE15, NE30, NE50, NE100, NE150, etc.

Be applicable:For the transportation of cement, stone, sand, coal, grain, ore, etc.

Wide range of promotion,Powder, granular, block and other materials can be lifted.

low driving power,The chain speed is low, the lifting capacity is

large, and the reactive power is small, and the power consumption is 70% of the chain power.

Large conveying capacity,The chain speed is low, the car conveying capacity is large, the operation is stable and the sealing is good.

long lasting,The surface of the carbon steel material of the plate chain chain is painted to prolongthe service life.

Low cost of use,Low energy consumption, less maintenance and low.

The structural design and working principle of the organic fertilizer bucket elevator ensure its stability during long-term operation. High-quality transmission components, firm hopper connection and stable casing structure enable the equipment to withstand the continuous loading of organic fertilizer and various stresses during operation. At the same time, a reasonable control system and overload protection mechanism can effectively prevent the equipment from being damaged due to abnormal conditions, ensuring the reliability of the equipment and reducing the time and frequency of equipment downtime for maintenance.

The operation of the equipment is relatively simple, and the operator can master the basic operation methods such as starting, stopping, and speed regulation after simple training. In terms of maintenance, the structure of the organic fertilizer bucket elevator is simple, and each component is easy to inspect and repair. The replacement of vulnerable parts such as hoppers, chains, and belts is convenient and quick, and there is also sufficient spare parts supply on the market. In addition, the cleaning and maintenance of the equipment is also relatively easy, which helps to extend the service life of the equipment.

The company provides a professional installation team to install the organic fertilizer bucket elevator to the location specified by the user. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.