Fertilizer palletizing production line

1. The use of advanced control systems and sensor technology can accurately control the position and posture of palletizing to ensure that the fertilizer packages are neatly and stably stacked on the pallet.

2. The equipment structure is relatively simple, the main components are highly reliable, the failure rate is low, and it is easy to repair and maintain.

3. The palletizing operation is carried out strictly in accordance with the preset procedures to avoid the randomness and errors that may occur during manual palletizing.

4. Through simple adjustments or programming settings, it can quickly adapt to fertilizer packages of different specifications, shapes and weights to meet the diversified production needs of enterprises.

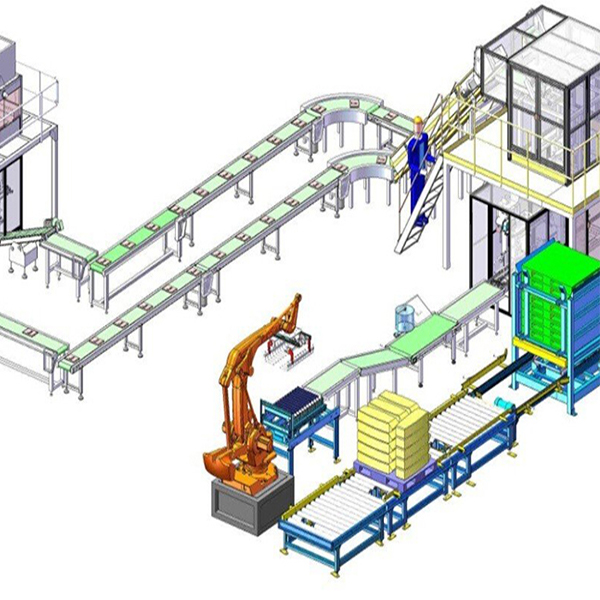

5. It supports multiple palletizing modes, such as horizontal palletizing, vertical palletizing, etc., and can also be customized according to the special requirements of customers to achieve different pallet designs.

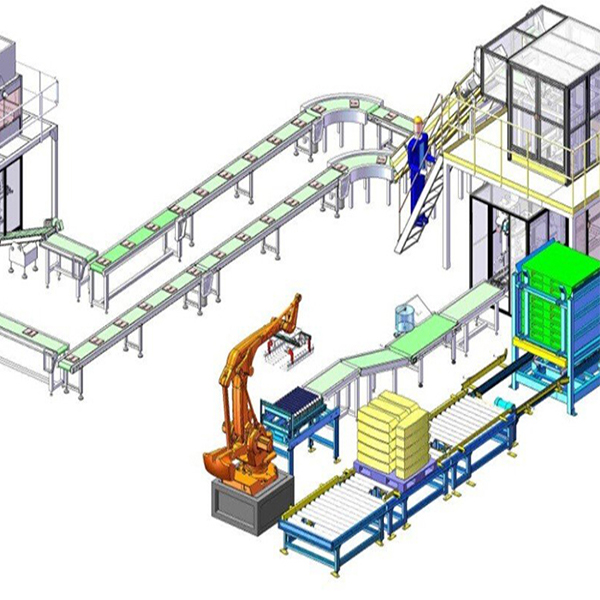

As a key equipment for modern fertilizer production enterprises, the Fertilizer palletizing production line integrates mechanical automation, intelligent control and precision sensing technology, aiming to efficiently, accurately and safely complete the series of processes of fertilizer products from packaging to standardized palletizing.

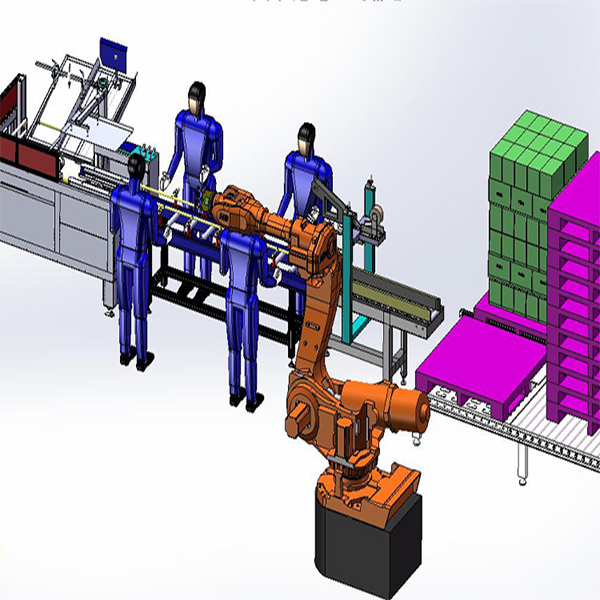

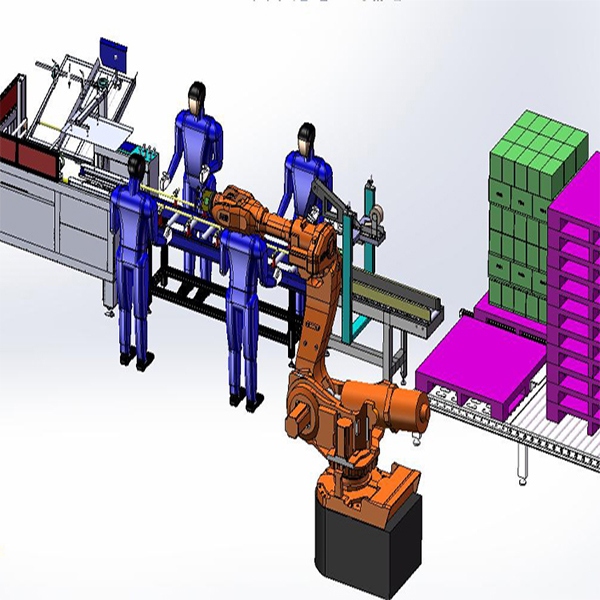

Equipped with high-performance robot arms or mechanical grippers, it can accurately grab and smoothly carry fertilizer packages according to different packaging forms. It can flexibly adapt to packaging in a wider weight range of 5kg - 50kg or even wider, and stack fertilizer packages on pallets in an orderly manner according to the preset stacking mode.

High-precision laser positioning and visual recognition systems are used to work together to monitor the position, posture and load condition of the fertilizer packaging in real time.

Supports a variety of common palletizing methods to adapt to different warehouse layouts and logistics transportation requirements. At the same time, it can also customize personalized palletizing solutions according to the special needs of enterprises.

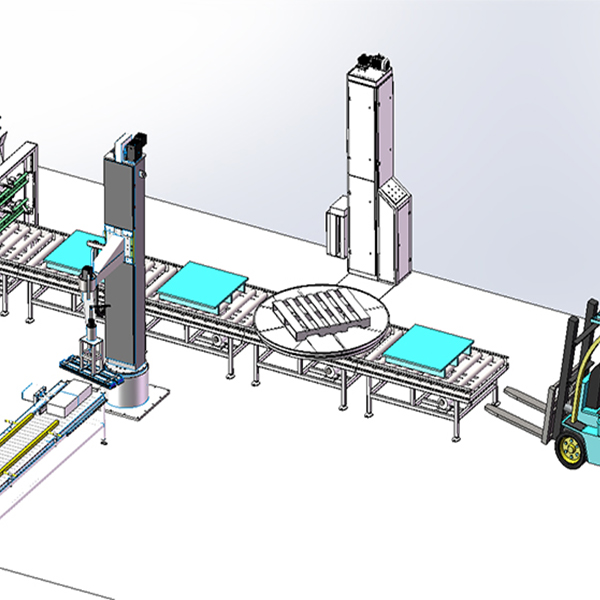

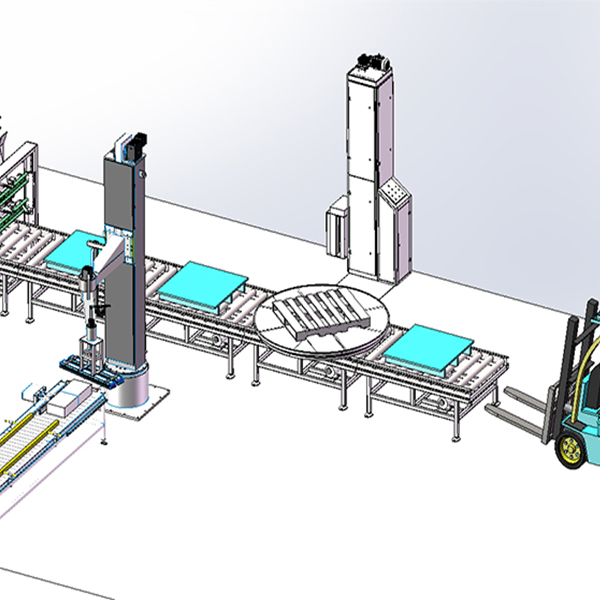

With excellent compatibility, it can seamlessly connect to the front-end fertilizer packaging production line and automatically receive the packaged products; the back-end can also efficiently connect with transportation equipment, forklifts and other logistics tools to achieve smooth material transportation from production to storage.

The highly automated operation mode has basically replaced the heavy and repetitive manual palletizing work, greatly reducing the company's manpower allocation in the palletizing process.With precise control systems and intelligent sensors, problems such as unevenness, looseness and easy to fall over that are common in manual palletizing are eliminated.

Equipped with multiple safety protection mechanisms such as safety light curtains, emergency stop buttons, overload protection, etc., which not only ensure the stable operation of the equipment, but also completely eliminate the safety hazards of operators when working around the equipment.