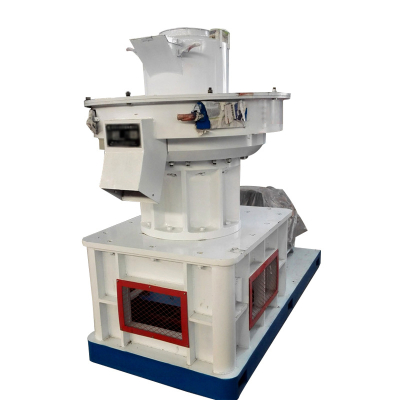

Drum agitator compound granulator

1. Good granulation effect: Combining the organic fertilizer stirring tooth granulation and drum granulation process, a new wet continuous push rod granulation process is adopted.

2. High work efficiency: Made by process processing, it has the characteristics of high bearing capacity, stable operation and high output efficiency.

3. Beautiful particles: The cylinder adopts special rubber plate or acid-resistant stainless steel lining plate, which can automatically remove scars and desulfurize the particles to maintain the sphericity of the particles.

4. Energy saving: There is no need to dry and crush the materials before granulation. Spherical particles can be processed by direct batching, saving a lot of energy and cost.

Organic fertilizer rotary drum agitator composite granulator is also called three-in-one granulator. This granulation equipment is a molding machine that can make materials into a specific shape. Through the combination of wet agitator granulation and rotary granulation, the pelletization rate of the pellets is higher, the pellets are more beautiful, and energy is saved.

The rotating gear compound granulator is one of the key equipment in the compound fertilizer industry. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The main working mode is wet granulation. A certain amount of water or steam is used to make the basic fertilizer fully chemically react after being humidified in the barrel. Under certain liquid phase conditions, the rotating motion in the barrel is used.

A model of high efficiency and energy saving: The equipment has efficient transmission and stable and reliable operation. The output of large-scale equipment can reach 5-10 tons per hour. The small and medium-sized models can stably achieve an output of 1-5 tons per hour depending on the specifications, meeting the demands of diversified scale production; and with the help of advanced Frequency conversion technology, optimized power transmission and heating and ventilation design reduce energy consumption by 10% - 20% compared with traditional granulation equipment, and the long-term operation can significantly reduce costs and increase efficiency.

Strong formula compatibility: It is highly adaptable to various compound fertilizer formulas, whether it is high-nitrogen type, high-potassium type, or complex formulas with multiple trace elements and bioactive ingredients added, it can be accurately processed into granules. The equipment parameters can be flexibly adjusted according to the characteristics of different formula materials to ensure smooth granulation and quality compliance.

Application areas:

Agricultural planting full scene: provide adaptive compound fertilizers for various crops such as food crops and cash crops, customize granules according to crop nutrient requirements, accurately release nutrients, and improve soil physical and chemical properties.

Garden garden fine maintenance: In the context of flower and lawn maintenance, the granular compound fertilizer produced by the drum mixing compound granulator has excellent slow-release characteristics, neat appearance, accurate fertilizer supply, and odor reduction.

Ecological restoration and improvement project: For damaged and degraded soils such as mining, land desertification, and saline-alkali land, the compound fertilizers it produces can specifically replenish nutrients and regulate soil pH and structure.