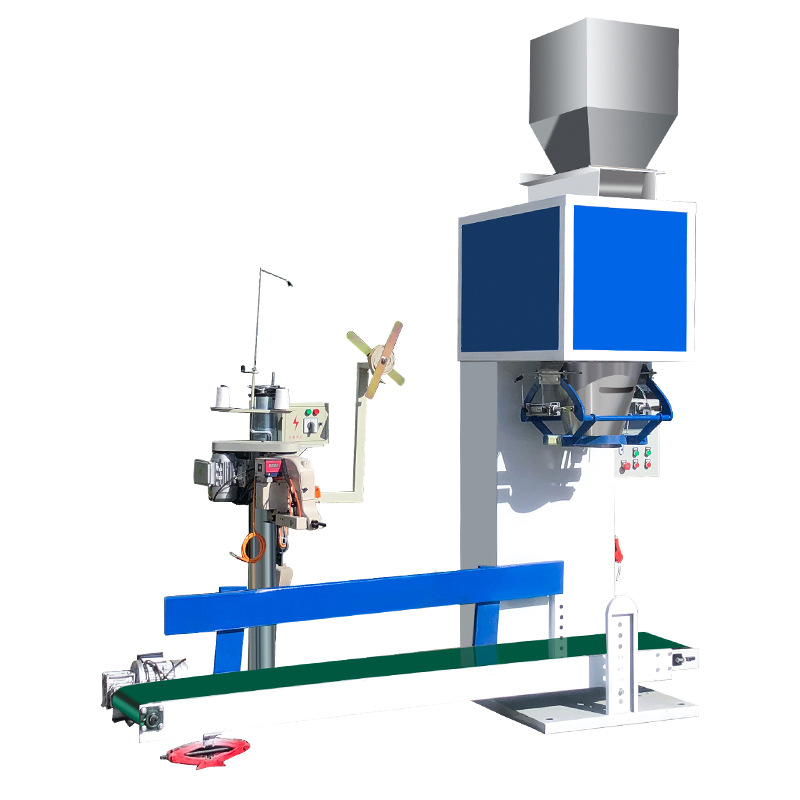

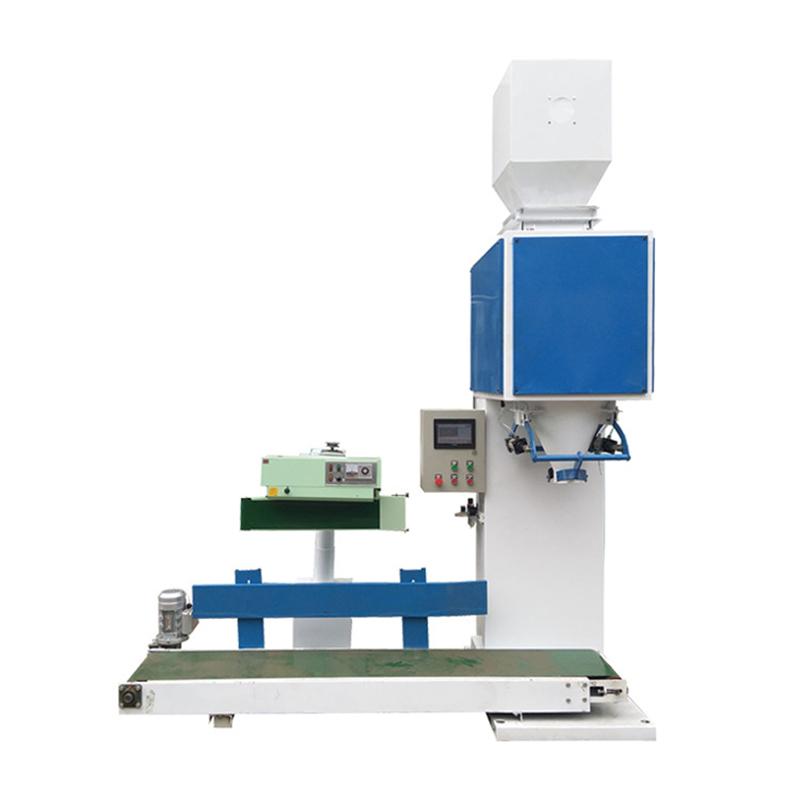

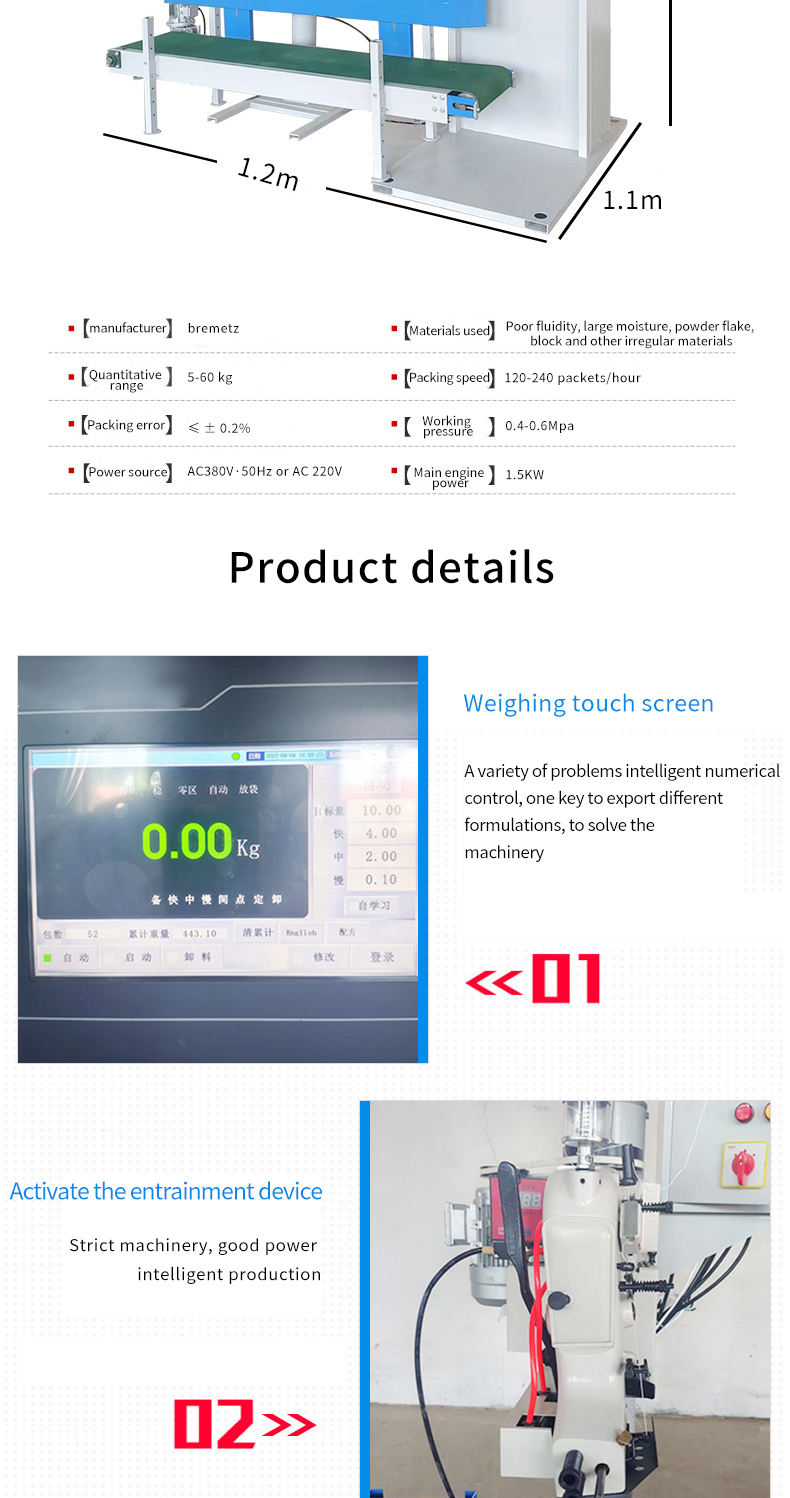

Automatic quantitative weighing pellet machine

1. The use of high-precision weighing sensors and advanced weighing control systems can accurately control the weight of the material.

2. Through the precisely designed granulation mold and stable extrusion system, particles with uniform size and regular shape can be produced.

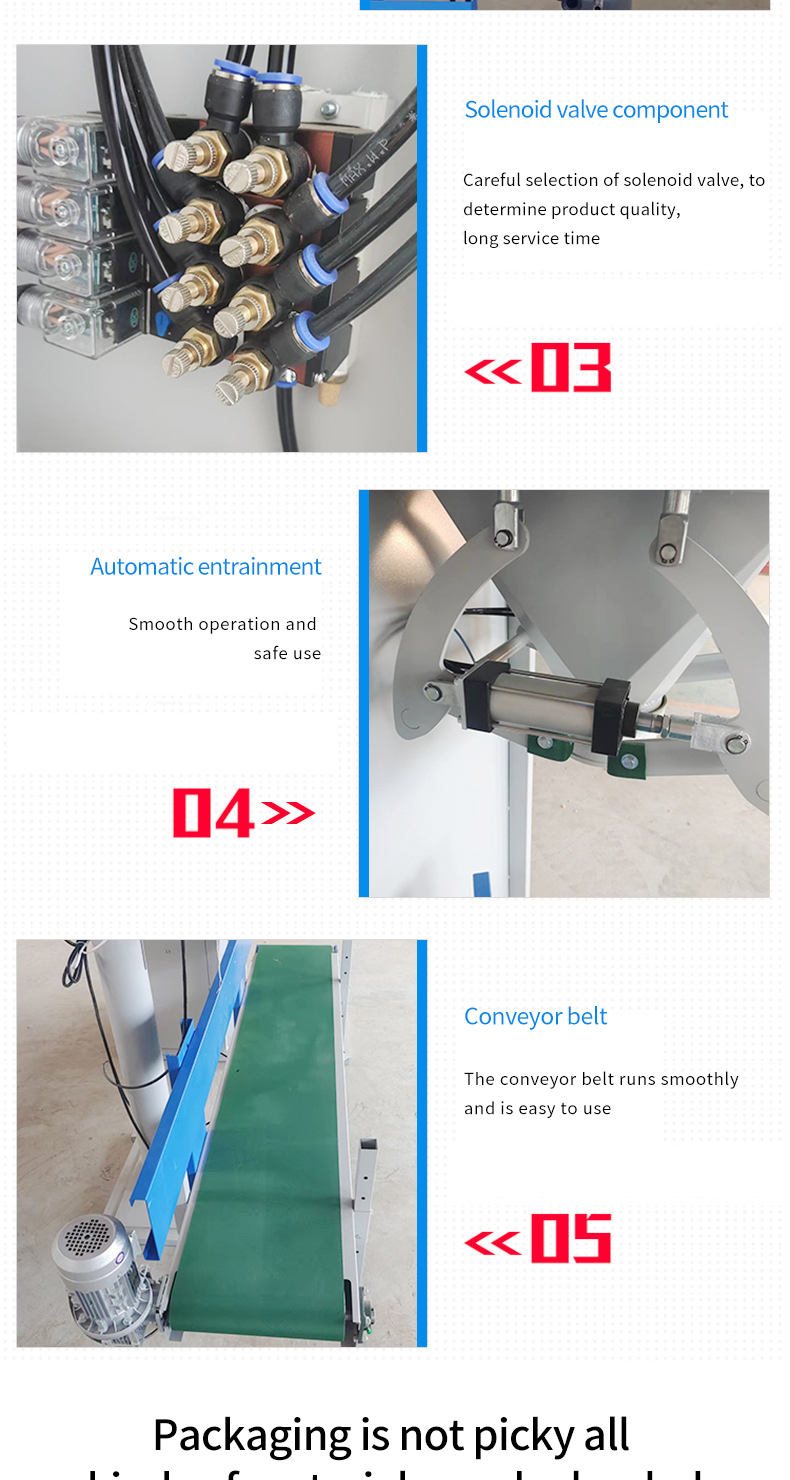

3. It has the functions of automatic feeding, weighing, granulation, and discharging, and the entire production process does not require frequent manual intervention.

3. Advanced granulation technology and efficient power system enable the material to complete the granulation process in a short time.

4. Using high-quality steel and advanced manufacturing technology, the overall structure of the machine is sturdy and can withstand long-term high-intensity operation.

5. Equipped with an advanced intelligent control system, it has fault self-diagnosis, automatic alarm and automatic protection functions.

The high-precision weighing system is combined with intelligent control to ensure accurate material quantification and provide a basis for stable product quality.

The machine has a high degree of automation, and the whole process from weighing to granulation is automatically operated, which greatly improves production efficiency and reduces labor costs.

Advanced granulation technology and high-quality molds make the particles regular in shape and uniform in density, thus improving product quality.

The user-friendly operation interface makes parameter settings simple and intuitive, so even novices can quickly get started.

The user-friendly operation interface makes parameter settings simple and intuitive, so even novices can quickly get started.

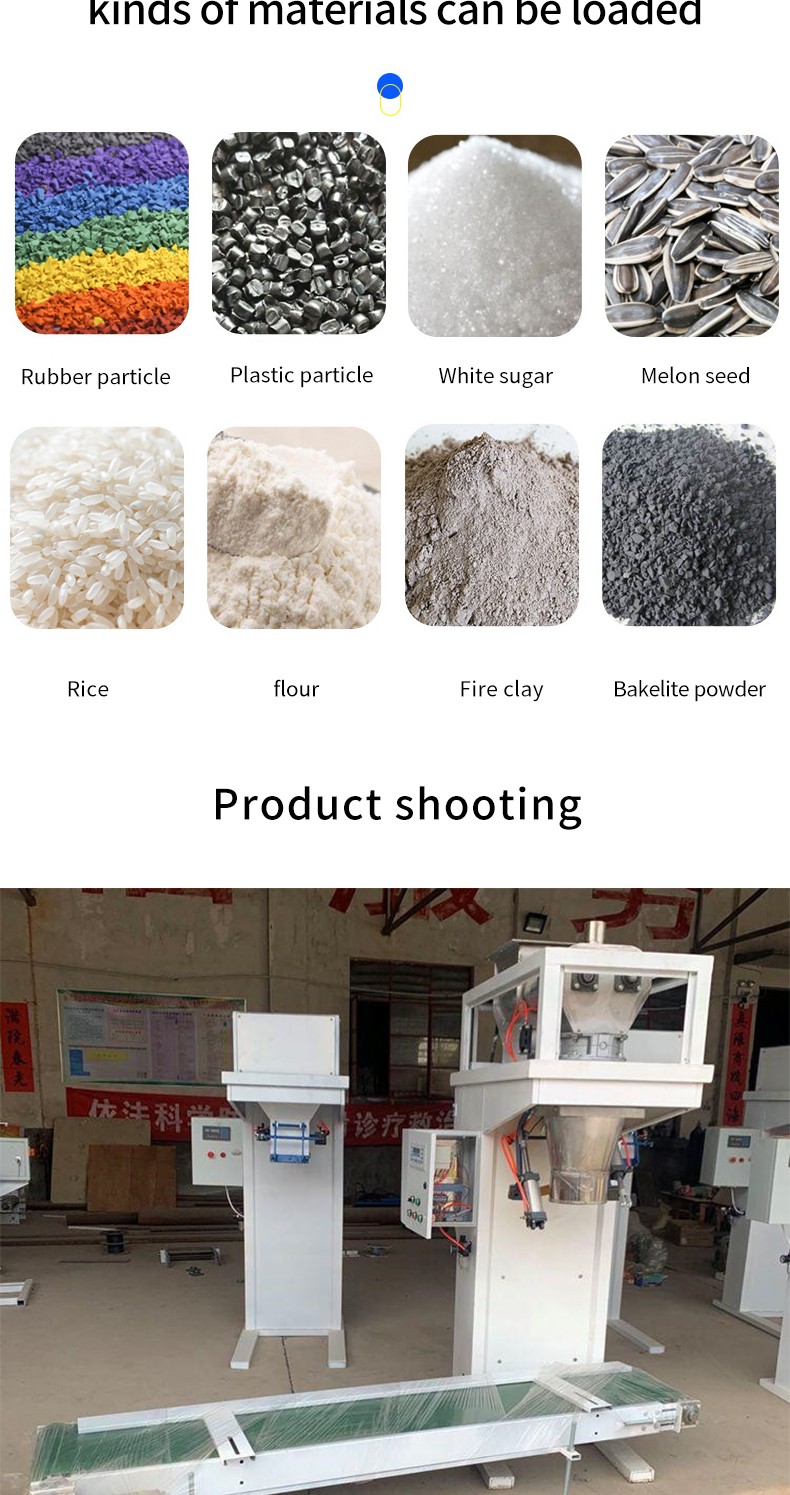

It is suitable for many industries such as feed, pharmaceuticals, chemicals, and food, and can handle materials with various characteristics.

Feed industry: various feed raw materials are made into nutritionally balanced and uniformly granulated feed to meet the feeding needs of different farmed animals.