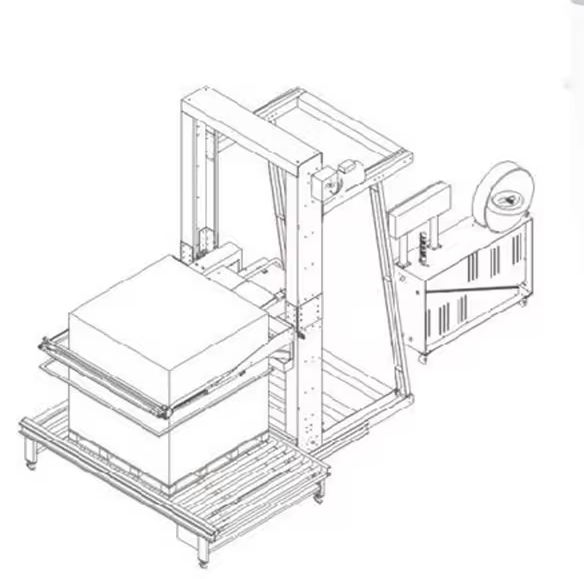

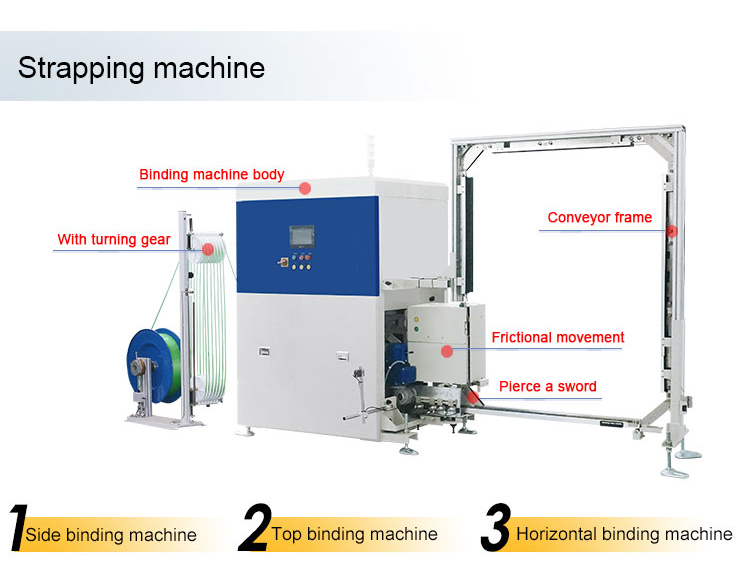

Sword strapping machine

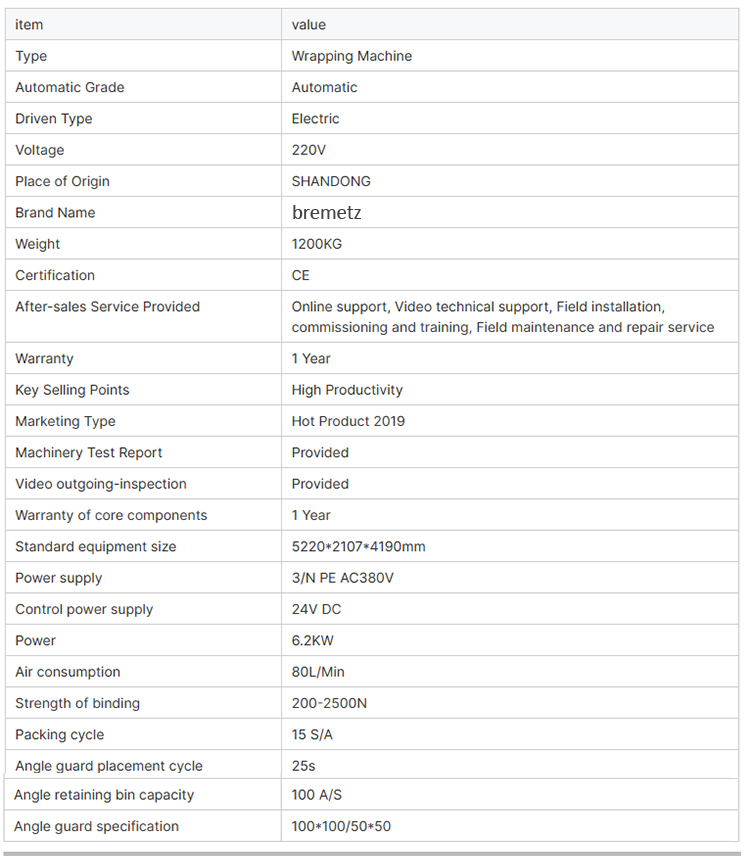

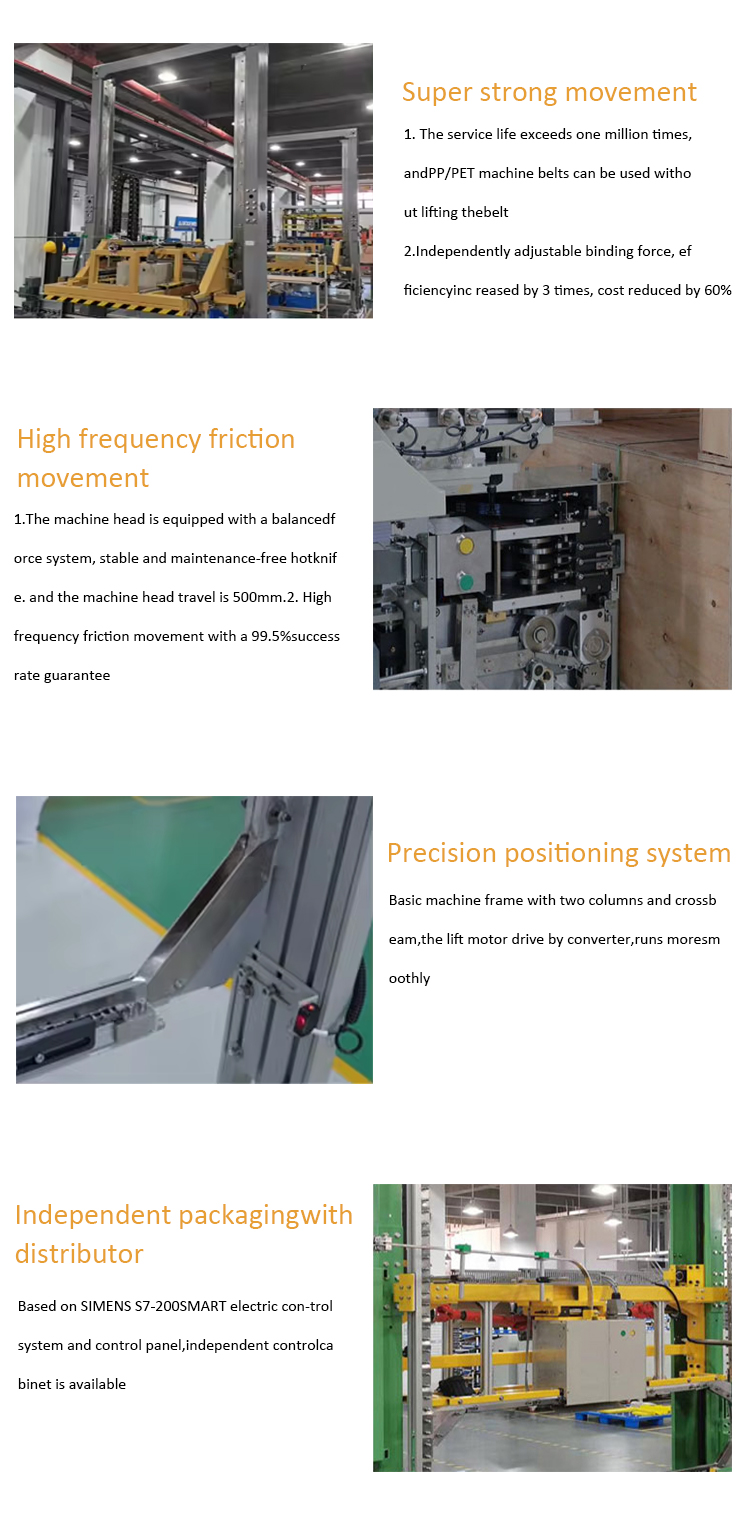

1. Equipped with high-precision positioning devices, it can accurately determine the position of the strapping tape, whether it is for regular-shaped products or slightly irregular objects.

2. It is usually designed with an adjustable working platform, track width, and strapping arm extension range, so that it can easily handle items of various sizes.

3. It supports strapping tapes of different materials such as common PP straps, PET straps, and steel straps. Users can flexibly choose the most suitable strapping material according to the packaged items.

4. The fuselage and key components are made of high-quality materials, and a strict quality inspection process is carried out to ensure that the equipment has stable and reliable performance under long-term and high-intensity use.

5. It is particularly suitable for strapping the top of items. Its unique sword-like structure can fit the strapping tape to the top with precise angles and strength.

In today's highly competitive packaging market, Sword Strapping Machine stands out with its unique design and excellent performance, providing efficient, accurate and reliable strapping solutions for many industries.The whole machine presents a refined and tough industrial aesthetic, with smooth lines and compact shape.

With optimized mechanical structure and intelligent control system, the sword-type strapping machine has extremely high strapping efficiency and can easily complete dozens of strapping operations per minute, far exceeding traditional manual strapping.

Equipped with a highly sensitive positioning device, whether it is a regular rectangular carton or a special-shaped package with a certain curvature, it can ensure that the strapping belt is accurately positioned, making each strapping neat and beautiful, effectively improving the product packaging image.

With flexible adjustment functions, the work surface, track width, etc. can be adjusted as needed, easily meeting various packaging requirements from small electronic equipment packaging boxes to large pallet goods.

The user-friendly touch screen operation interface is equipped with a concise and easy-to-understand operation guide. Operators only need a short training to master the operation and easily control the start, stop, parameter setting and daily maintenance of the equipment.

Equipped with multiple safety protection measures such as overload protection, leakage protection, emergency stop button, protective door interlock, etc., to protect the safety of operators in all aspects and ensure that the equipment runs stably in a safe environment.