Organic fertilizer packaging machine

1. Organic fertilizer packaging machines are usually equipped with high-precision weighing sensors and advanced metering control systems.

2. In addition to weight measurement, some high-end organic fertilizer packaging machines also support volume measurement or counting measurement.

3. Organic fertilizer packaging machines have efficient packaging speed and can complete the packaging task of a large amount of fertilizer in a short time.

4. The key components of the equipment are made of high-quality materials and advanced manufacturing processes to ensure that the machine can operate stably during packaging operations.

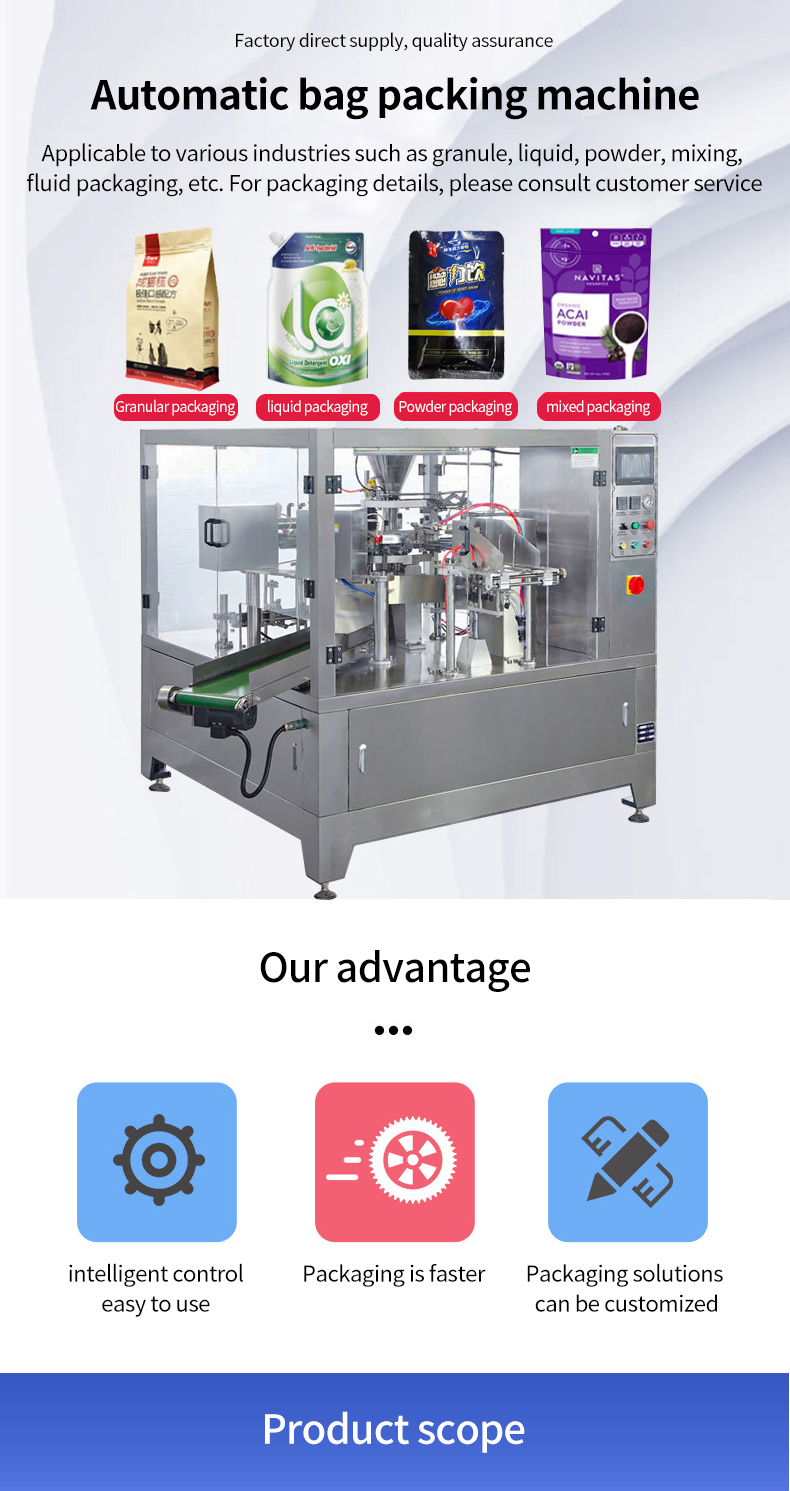

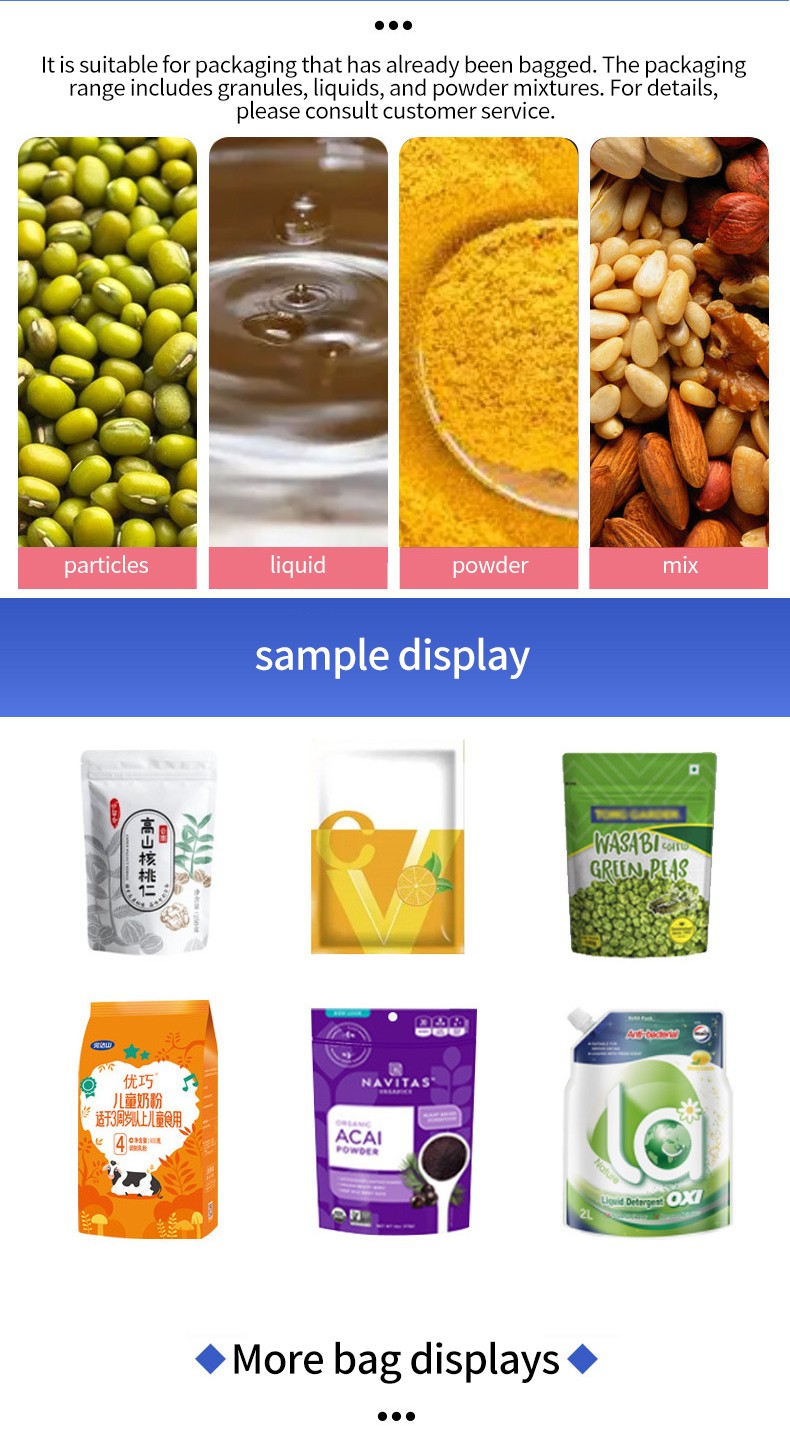

5. Organic fertilizers come in various forms, including granules, powders, blocks, etc. Organic fertilizer packaging machines can adapt well to these different forms of fertilizers.

Organic fertilizer packaging machine is an automated packaging equipment specially designed for organic fertilizer production enterprises. It aims to complete the packaging task of organic fertilizer efficiently and accurately, and meet the market requirements for organic fertilizer packaging quality and production efficiency.

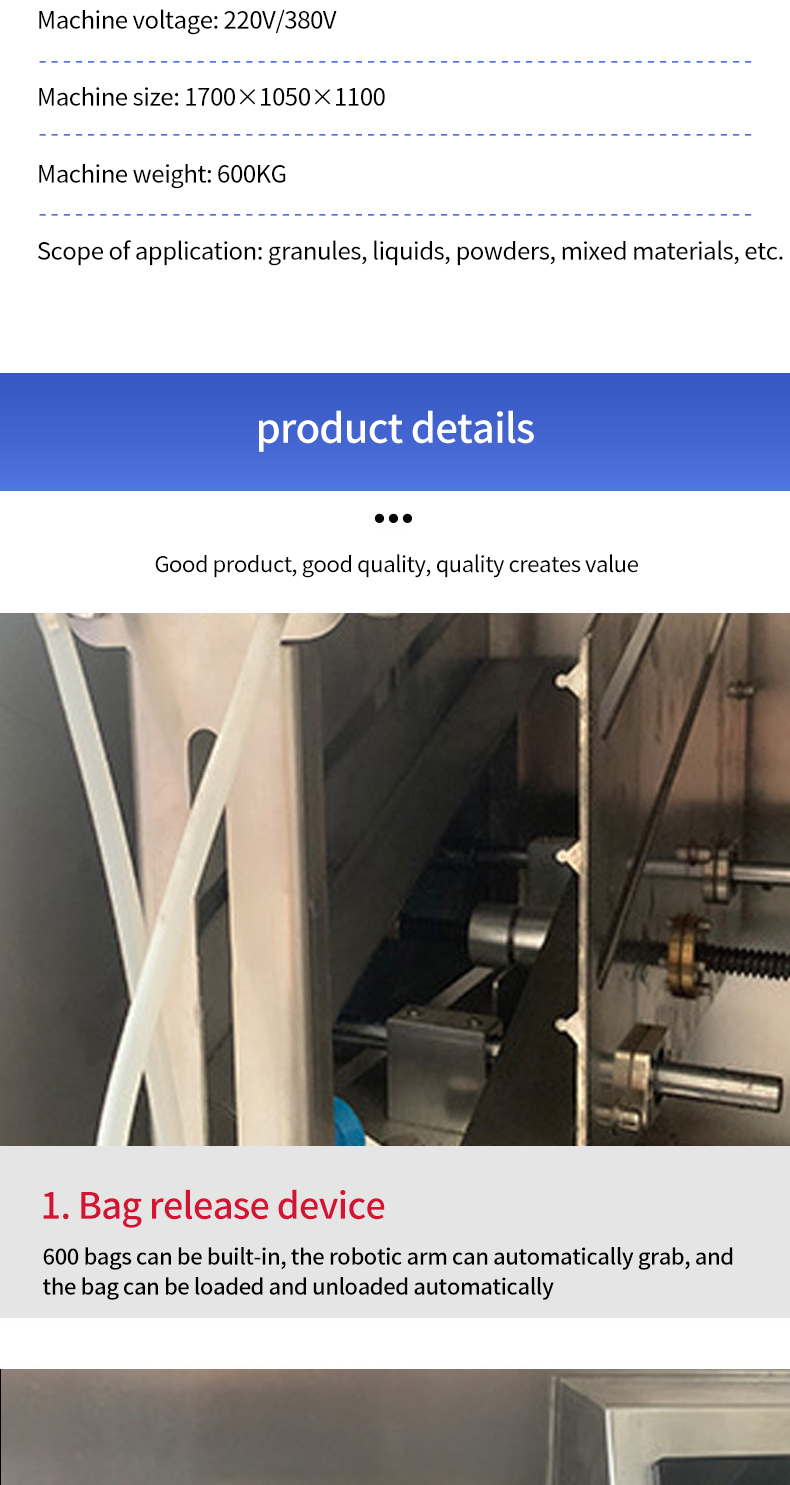

The vibrating feeder uses the vibration force generated by the vibrating motor to fluidize the organic fertilizer in the hopper and evenly enter the metering device; the spiral feeder pushes the organic fertilizer through the rotation of the spiral blade.

The metering controller accurately controls the start and stop of the feeding system according to the preset packaging weight parameters. When the target weight is reached, the feeding is stopped immediately to achieve accurate metering of organic fertilizer.

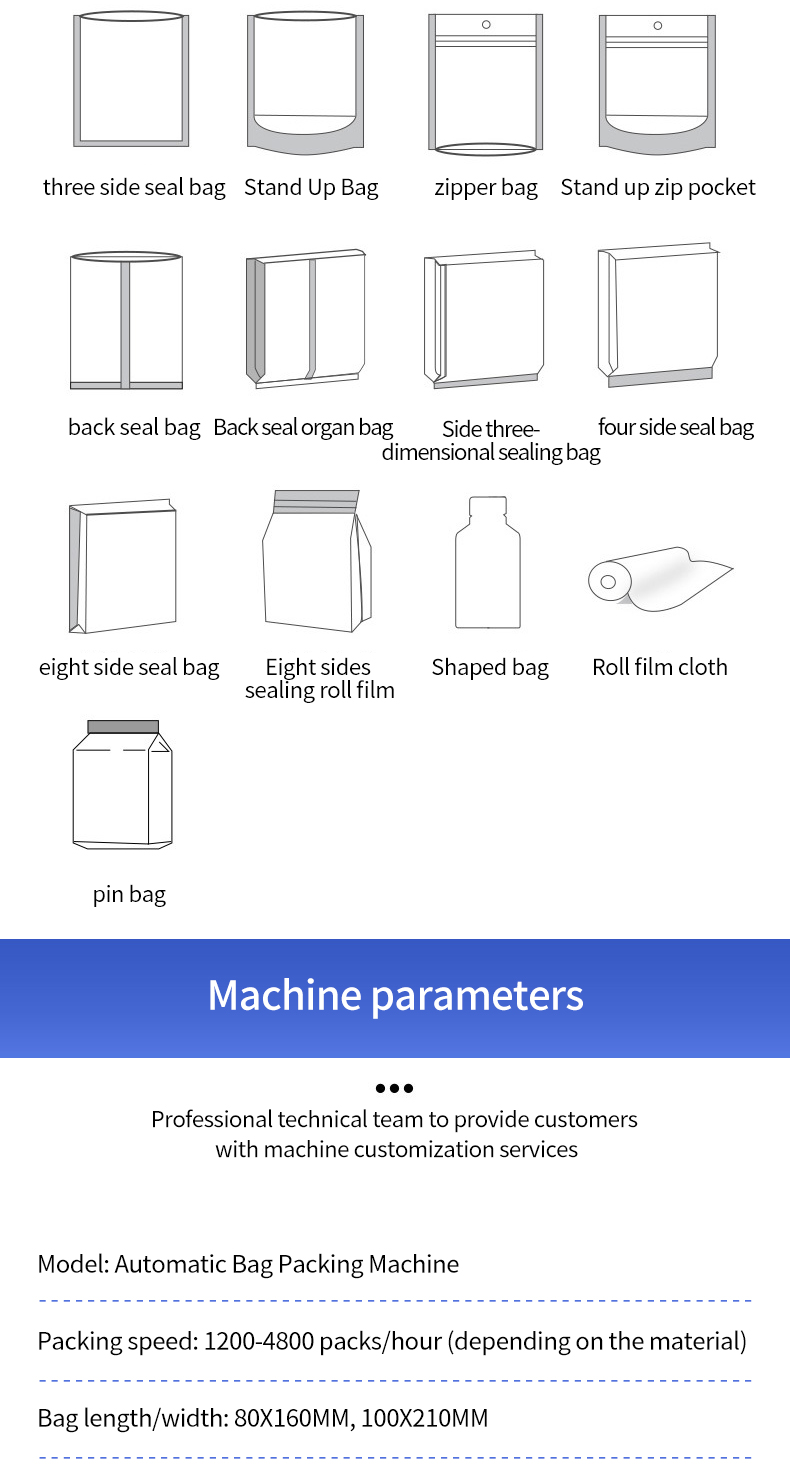

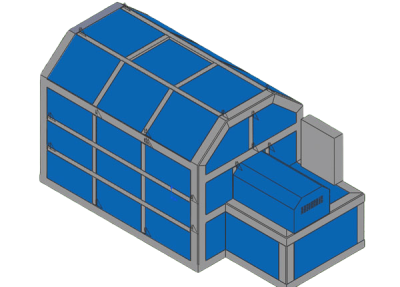

Model: Automatic Bag Packing Machine

Packing speed: 1200-4800 packs/hour (depending on the material)

Bag length/width: 80X160MM, 100X210MM

Machine voltage: 220V/380V

Machine size: 1700×1050×1100

Machine weight: 600KG

Scope of application: granules, liquids, powders, mixed materials, etc.

The packaging film roll holder can be installed with packaging film rolls of different specifications and materials, such as plastic film, paper film or composite film, etc., so that the film roll can be replaced conveniently and quickly.

The machine body adopts a solid metal frame structure, generally made of high-quality carbon steel or stainless steel. After fine welding and processing, it has sufficient strength and stability to withstand various vibrations and impacts during the packaging process.