Granule filling and packaging machine

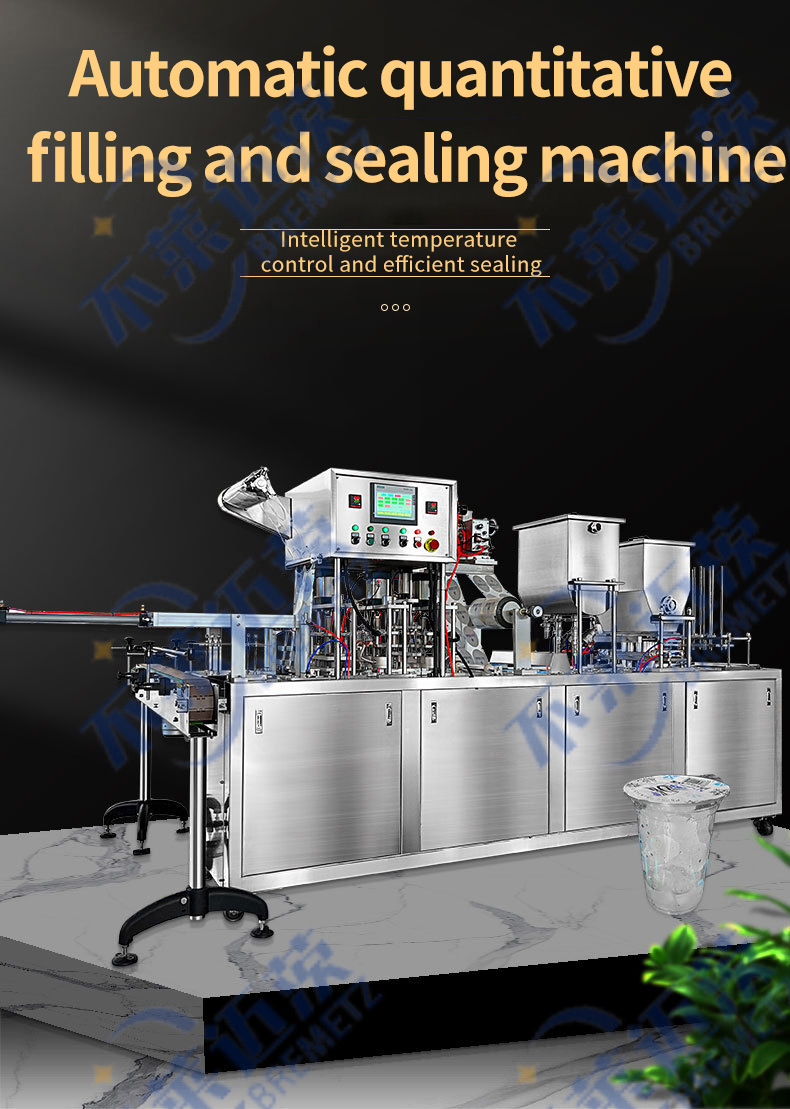

1. It can automatically complete a series of packaging processes such as material conveying, metering, filling, and sealing, greatly reducing manual operation time.

2. Its design and operating principle enable it to quickly complete the packaging of granular materials, and can process a large number of products in a short time to meet the needs of large-scale production.

3. The use of high-precision sensors and metering devices, such as advanced weighing sensors and intelligent control systems, can accurately control the filling amount of granular materials.

4. Through precise mechanical control and automated operation, the shape, size and other specifications of the packaging can be highly consistent.

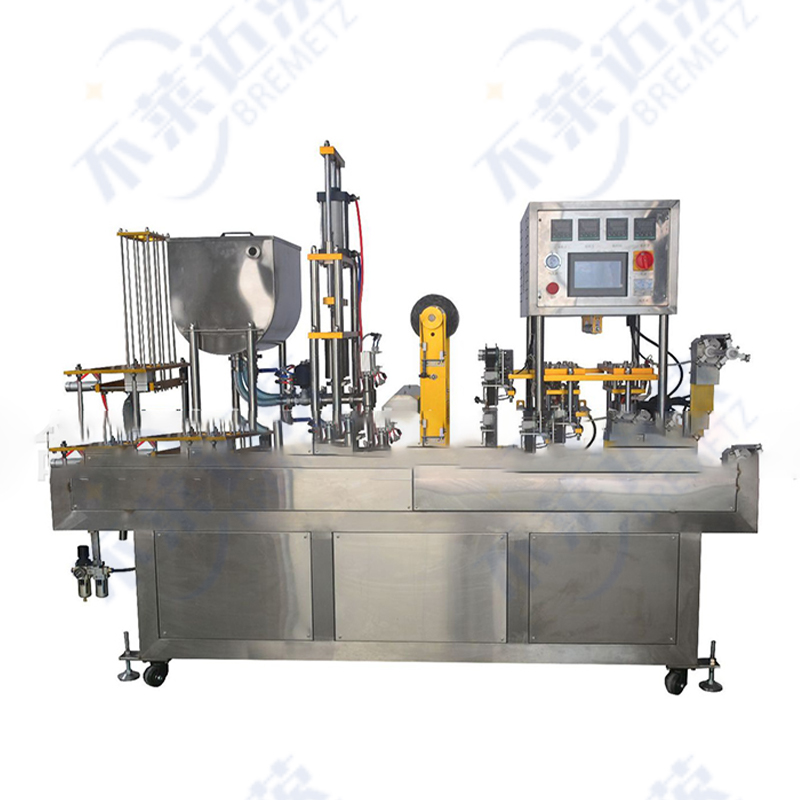

5. The body is mostly made of stainless steel and other materials that meet the food hygiene and drug production quality management standards, and the parts that contact the materials are also specially treated.

Granular filling and packaging machine is an advanced equipment specially used for accurate metering and packaging of granular materials. It is widely used in many industries such as food, medicine, chemical industry, agriculture, etc.

The use of advanced sensors and signal processing technology has achieved ultra-high precision measurement of granular materials.

The metering system has a dynamic compensation function, which can automatically adjust the metering parameters in real time according to factors such as changes in material fluidity, changes in ambient temperature and humidity, and equipment operation wear.

The intelligent filling control algorithm developed based on big data analysis and artificial intelligence technology is another core highlight of the granule filling and packaging machine.

In the actual packaging process, the intelligent filling control algorithm can monitor parameters such as material flow and pressure changes in real time during the filling process, and dynamically adjust the filling strategy according to the changes in these parameters.

It can process various granular materials of different shapes, sizes, densities and fluidities. Whether it is fine pharmaceutical particles, food additive particles, or larger feed particles, plastic particles, etc.

With its automated packaging process, advanced mechanical structure and high-performance power system, the granule filling and packaging machine has extremely high packaging efficiency.

Energy conservation and environmental protection factors are fully considered in the design and manufacturing process. The equipment uses energy-saving motors and drivers, optimizes the power transmission system, and reduces the operating energy consumption of the equipment.