Fully automatic powder granule packaging machine

1. High-precision weighing system: equipped with advanced weighing sensors and precise metering control technology, it can quantify powder or granular materials with high precision and a very small error range.

2. Multiple metering methods are available: in addition to weighing and metering, some models also support volumetric metering and other methods, which can be flexibly selected according to the characteristics of the material to further improve the accuracy and adaptability of the metering.

3. High-speed automated operation: it realizes a fully automated process from material conveying, metering, filling, sealing to finished product output, with fast packaging speed.

4. Continuous and stable operation: it adopts high-quality mechanical structure and advanced control system, has good stability and reliability, and can operate continuously for a long time without failure.

5. Ability to handle special materials: For some materials with special properties, such as powders or granules that are easy to absorb moisture and agglomerate, the equipment can ensure the smooth progress of the packaging process and ensure that the product quality is not affected through special design and configuration.

6. Accurate filling and molding: During the filling process, it can ensure that the material is evenly and accurately filled into the packaging bag to avoid material accumulation or partial vacancies.

Fully Automatic Powder Granule Packaging Machine is an advanced equipment specially used for automatic packaging of powder and granular materials. It integrates multiple functions such as high-precision metering, filling, sealing and automatic control. It is widely used in many industries such as food, medicine, chemical industry, agriculture, etc., and can meet the needs of enterprises of different sizes for efficient and accurate packaging of powder and granular products.

With the synergy of high-precision weighing sensors and advanced control systems, extremely accurate quantitative weighing of materials is achieved with a very small error range, which effectively ensures the consistency of product packaging weight and avoids quality problems caused by inaccurate measurement, such as overweight or underweight products affecting sales and use. It also helps companies to strictly control production costs and reduce waste of raw materials.

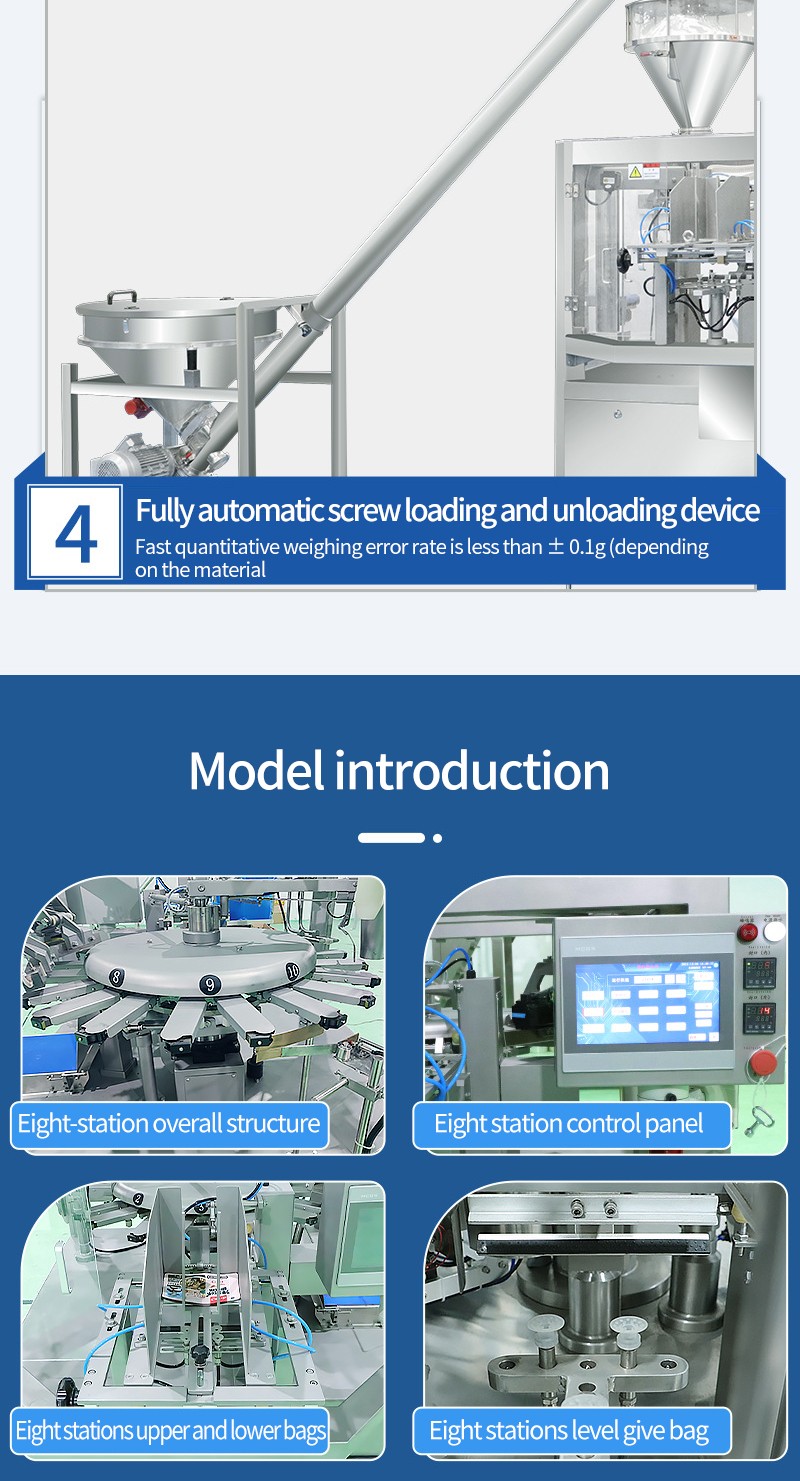

One-button automatic bag width adjustment Eight stations can be adjusted at the same time, only one button is needed to change the bag.

zipper device, For bags with zippers, this device can be added.

Full servo vacuum feeding device,Fast quantitative weighing error rate is lower than ±0.1g (depending on the material).

Fully automatic screw loading and unloading device,Fast quantitative weighing error rate is less than ± 0.1g (depending on the material).

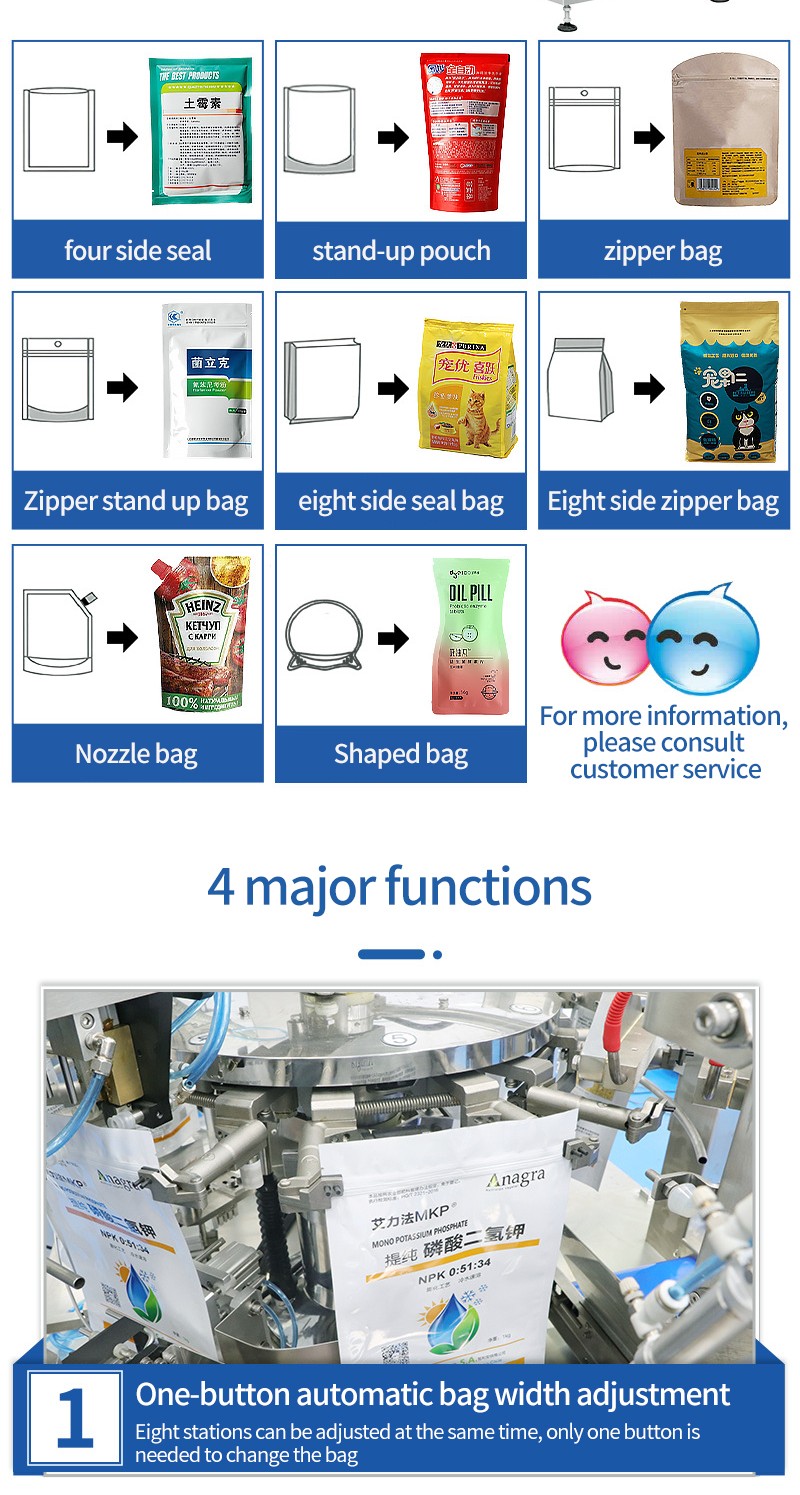

It can handle materials in various forms (such as powders, granules, etc.) and with different properties (such as viscosity, fluidity, etc.), and can flexibly adjust packaging specifications and bag types. It only needs to simply configure or replace some accessories to adapt to the packaging requirements of different industries and different products. It has strong versatility and is widely used in many fields such as food, medicine, chemical industry, agriculture, etc.

Packaging machine parameters

name:Bag Type Powder Packaging Machine

model:GY-200,GY-250,GY-300

Suitable for bag type:Stand-up pouch, zipper bag, special-shaped bag, four-side seal bag, paper bag, eight-side seal bag, etc.

Adaptation range:Powder type is suitable for flour, edible soda powder, traditional Chinese medicine powder and other materials.

packing speed:80bags/min Look at the material,80bags/min Look at the material,80bags/min Look at the material.

bag size:L≤360mm, W≤250mm,L≤360mm, W≤300mm,L≤360mm, W≤210mm.

Air consumption:6Kg/m², 0.4m³,6Kg/m², 0.4m³,6Kg/m², 0.4m³

power:380V/8.5KW,380V/8.5KW,380V/8.5KW

weight:about 700kg,about 700kg,about 720kg

External dimensions:1950*1400*1520 (mm),1950*1400*1520 (mm),2100*1500*1520 (mm)

Whether it is filling, sealing or other packaging links, high-quality operating results can be guaranteed, so that the finished packaging product has a neat and beautiful appearance, a firm seal and good sealing, which effectively improves the overall image and market competitiveness of the product. At the same time, it also ensures the quality and safety of the product during storage and transportation, and enhances consumers' trust in the product.

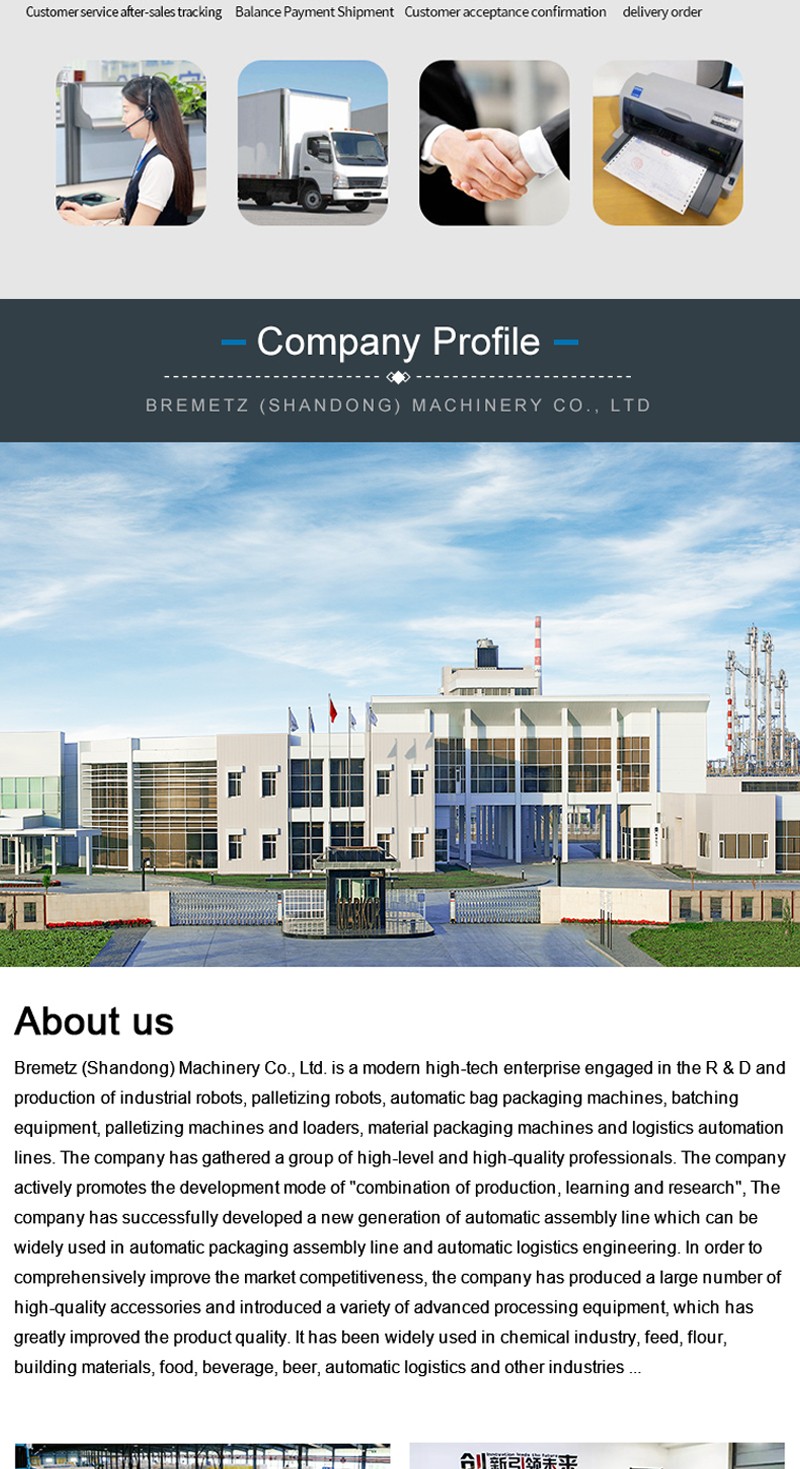

Our professional technical team will provide on-site installation services and perform precise installation according to site conditions and equipment requirements to ensure that all equipment components are firmly connected and reasonably laid out.

Provide users with comprehensive operation training and maintenance training, including on-site training and remote training. During on-site training, experienced engineers will provide one-on-one guidance to operators at the equipment installation site, explaining in detail the equipment's operation methods, parameter settings, daily maintenance points, and common fault handling measures, etc., to ensure that operators can master and use them correctly. Remote training can provide users with continuous technical support and answer questions during subsequent use, so that users can solve problems in a timely manner and ensure the normal use of the equipment.

We continue to pay attention to the development of industry technology, provide users with technical upgrade services for equipment in a timely manner, and continuously improve the performance, function and intelligence level of equipment through software updates, hardware improvements, etc., so that the equipment always maintains advanced performance and meets the growing production needs and market competition requirements of users.

We have sufficient stock of original spare parts, including key components of the equipment (such as weighing sensors, motors, conveyor belts, filling devices, sealing components, etc.) and commonly used control components, to ensure that when equipment fails and parts need to be replaced, the required spare parts can be provided in time, shortening equipment downtime and reducing the impact on user production operations.

In short, Fully Automatic Powder Granule Packaging Machine has become an indispensable packaging equipment in many industries with its advanced functions, excellent performance, wide applicability and perfect after-sales service system. It has provided strong support for enterprises to achieve efficient, accurate and high-quality product packaging, and promoted the automation and standardization of product packaging links in various industries.