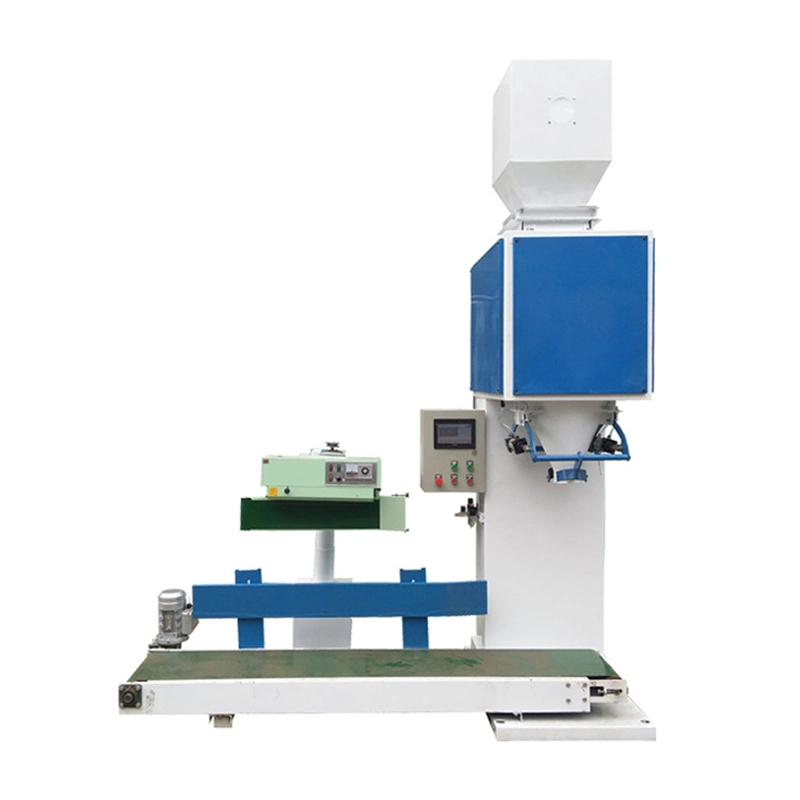

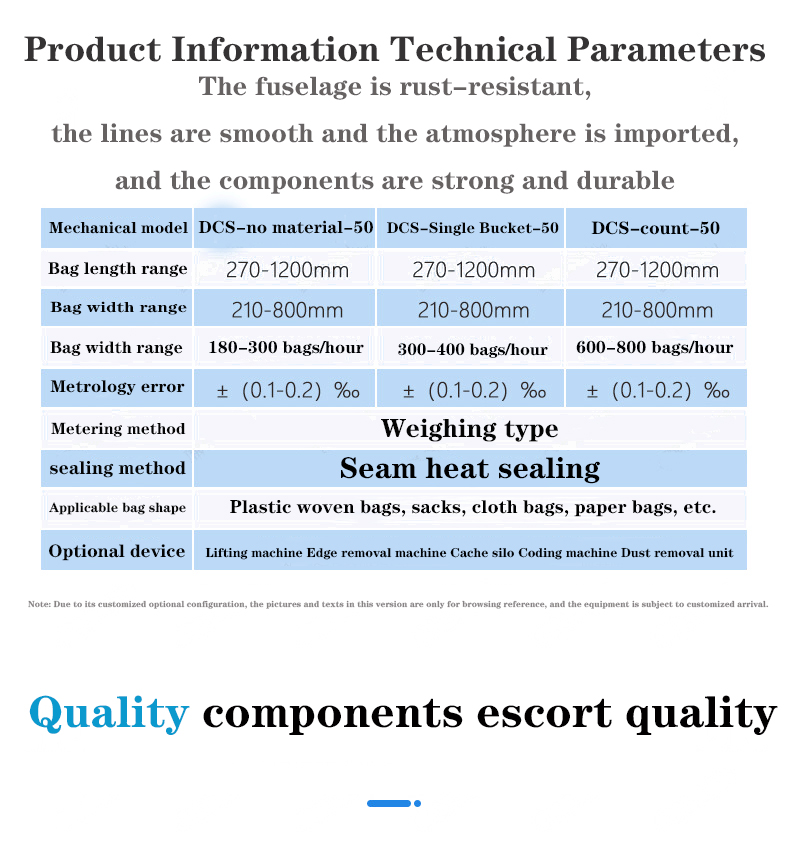

Spiral powder packaging machine

1. It can control the discharge amount of powder more accurately. By adjusting the speed, pitch and other parameters of the spiral, it can achieve accurate measurement of powders of different weights.

2. Equipped with high-precision weighing sensors, it can provide real-time weighing feedback on the material based on the spiral feeding, further improving the accuracy of measurement.

3. The spiral structure can achieve continuous and stable material transportation, which greatly improves the packaging efficiency compared to other intermittent feeding methods.

4. It can handle a variety of powder materials of different properties. For some powders that are easy to agglomerate and dust, the corresponding stirring device or vibration device can be equipped to keep the material in good fluidity.

5. The speed of the spiral, the size of the feeding port and other parameters can be flexibly adjusted according to the characteristics of the material to meet the packaging needs of different materials.

The spiral powder packaging machine is an advanced equipment specially used for packaging powder materials. It is widely used in many industries such as food, chemical industry, building materials, etc. It can achieve accurate measurement and efficient packaging of powder materials through the unique spiral metering principle and combined with the automated packaging process.

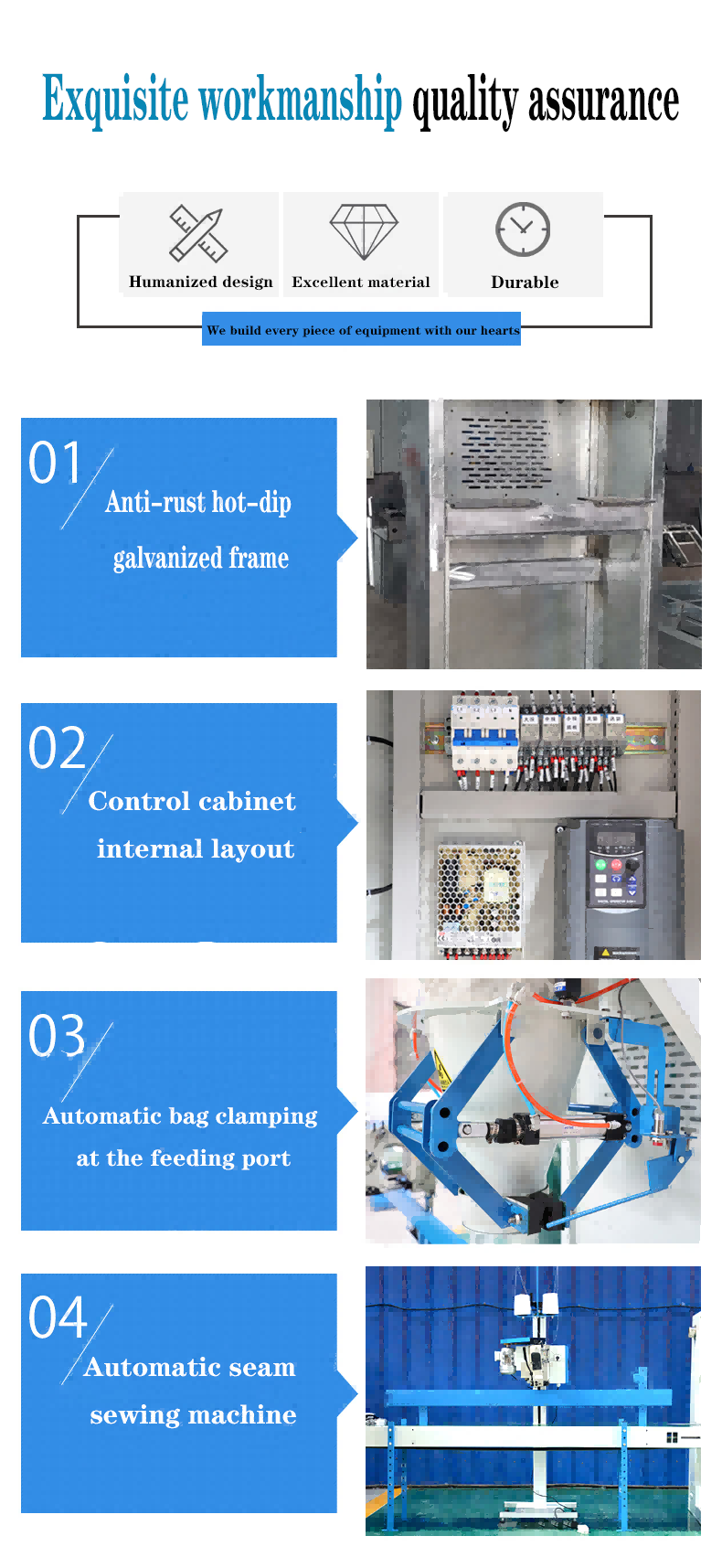

The spiral metering device adopts advanced frequency conversion speed regulation technology, which can accurately control the speed of the spiral shaft, thereby achieving precise regulation of the powder material flow rate.

The intelligent control system can not only achieve precise control of the basic functions of the equipment, but also has a variety of intelligent functions.

In addition to providing a convenient human-computer interaction interface, the automated operation software also has production data management and statistical analysis functions.

Regardless of the nature of the powder material, such as flour and chemical powder with different fluidity, or milk powder and pigment powder with different densities, the spiral powder packaging machine can achieve high-precision metering.